3-5. Disassembly, Reassembly and Lubrication

3-17 CLP-621 & CLP-631

Notes on reassembling:

• Distinguish the Ribbon Tension Spring F (used here) and the Ribbon Tension Spring R (used in

the next 3-5-9 “Ribbon Tension Shaft R SA”). They look like the same, but the number of turns

differs.

18 turns (Spring F, Ribbon Tension)

20 turns (Spring R, Ribbon Tension)

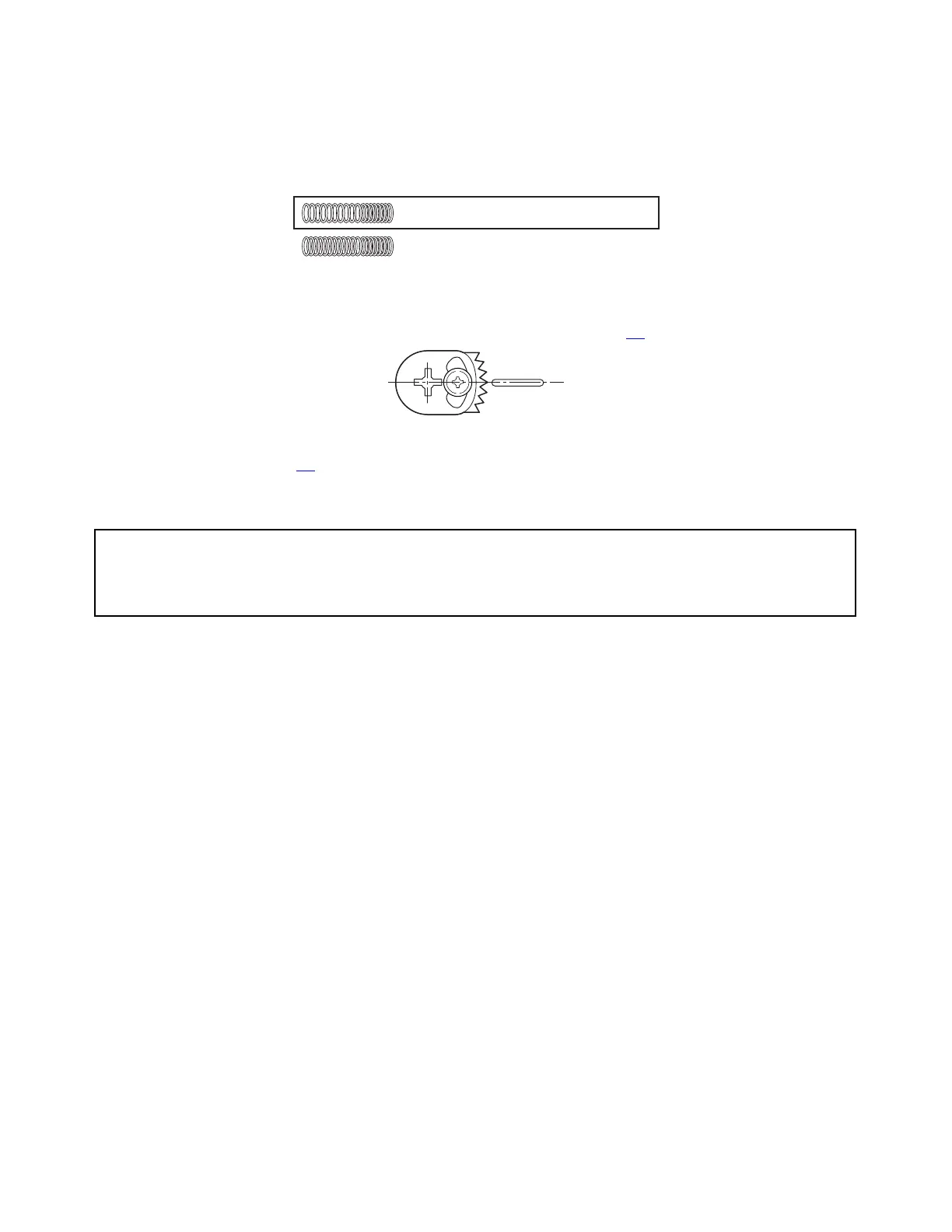

• When assembling the Tension Base Adjust Cam, adjust its position as shown in the figure to set

it at the mechanical center. Then, perform adjustment according to 3.6.2-(2-1) “Tension base

adjust cam position adjustment (For service personnel)” on page 3-

47.

• When assembling the tension adjust screw (PH, M1.7x4), perform 3-6-3 “Ribbon Tension

Adjustment” on page 3-

52.

3-5-9. Ribbon Tension Shaft R SA and Tension Sensor SA

Caution:

DO NOT disassemble the Tension Base Adjust Cam and tension adjust screw (PH,

M1.7x4) unless you need to replace them.

1. Open the Top Cover SA.

2. Remove the Ribbon Sensor R Unit. Refer to 3-5-7 “Ribbon Sensor F/R Unit”.

3. Remove 2 screws (NO.0, TFH (BT), M2x4 (NI)) at both ends, and detach the Ribbon Tension

Shaft R SA and Ribbon Guide Roller Bush 2 (2 pcs.).

4. Remove 1 screw (PH (PW), M2x8), and detach the Tension Adjust Lever R Block and Tension

Adjust Shaft.

5. Remove the Ribbon Sub Adjust Lever R SA and Ribbon Tension Spring R (2 pcs.) from the

Tension Adjust Lever R SA.

6. Remove the tension adjust screw (PH, M1.7x4) from the Tension Adjust Lever R SA.

Note: Do not remove this tension adjust screw unless you need to replace it.

7. Remove 2 screws (NO.0, TFH, M2x3 (NI)) and detach the Tension Sensor SA.

8. Remove 1 screw (NO.0, TFH, M2x3 (NI)), and detach the Tension Base Adjust Cam from the

Ribbon Sensor Frame R SA.

Note: Do not remove the Tension Base Adjust Cam unless you need to replace it.

Loading...

Loading...