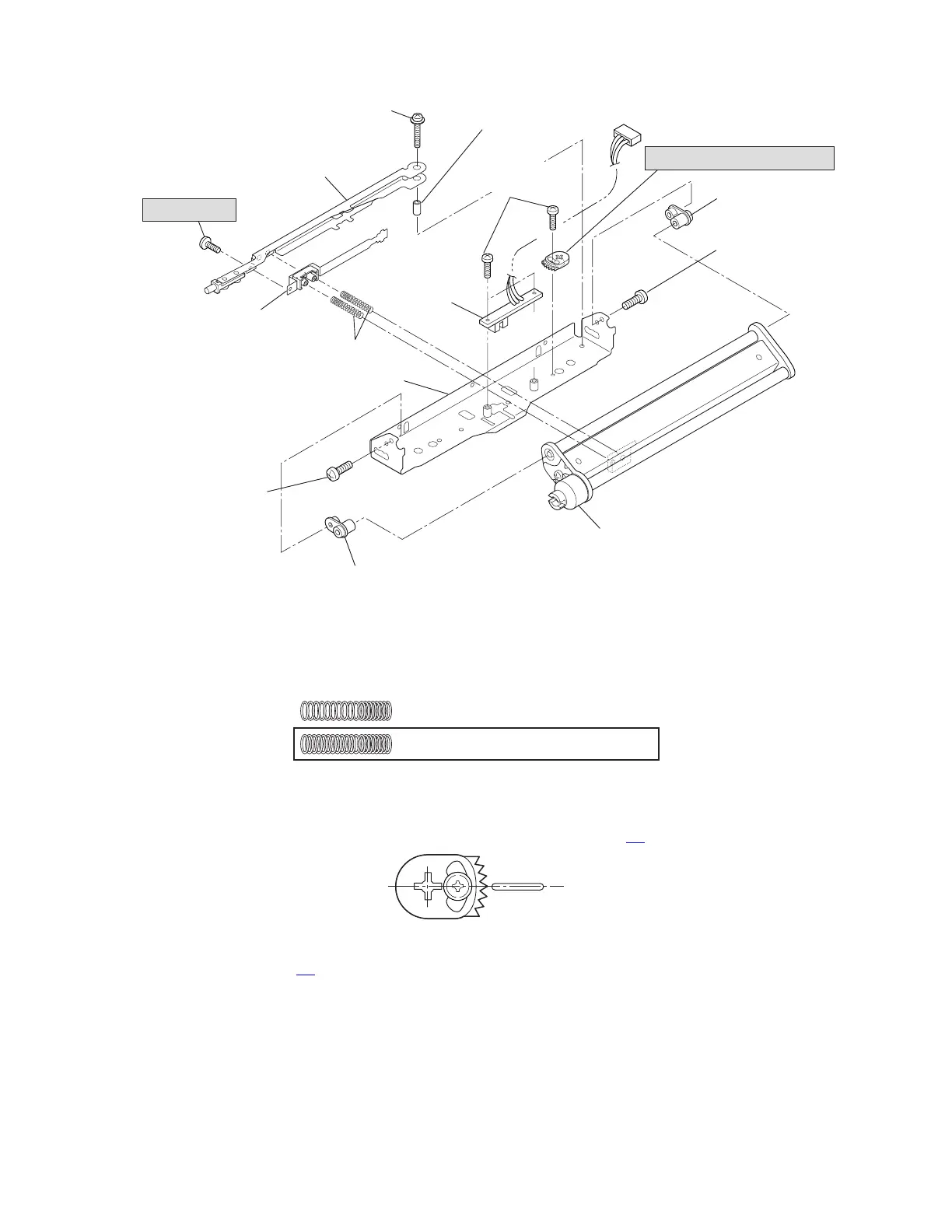

3-5. Disassembly, Reassembly and Lubrication

CLP-621 & CLP-631 3-18

SA, Ribbon Tension Shaft R

NO.0, TFH (BH),

M2x4 (NI)

NO.0, TFH (BH),

M2x4 (NI)

SA, Ribbon Sensor Frame R

Spring R, Ribbon Tension

SA, Ribbon Sub Adjust Lever R

SA, Tension Adjust Lever R

SA, Tension

Sensor

PH (PW), M2x8

NO.0, TFH,

M2x3 (NI)

Bush 2, Ribbon

Guide Roller

Bush 2, Ribbon Guide Roller

Shaft, Tension Adjust

Cam, Tension Base Adjust

PH, M1.7x4

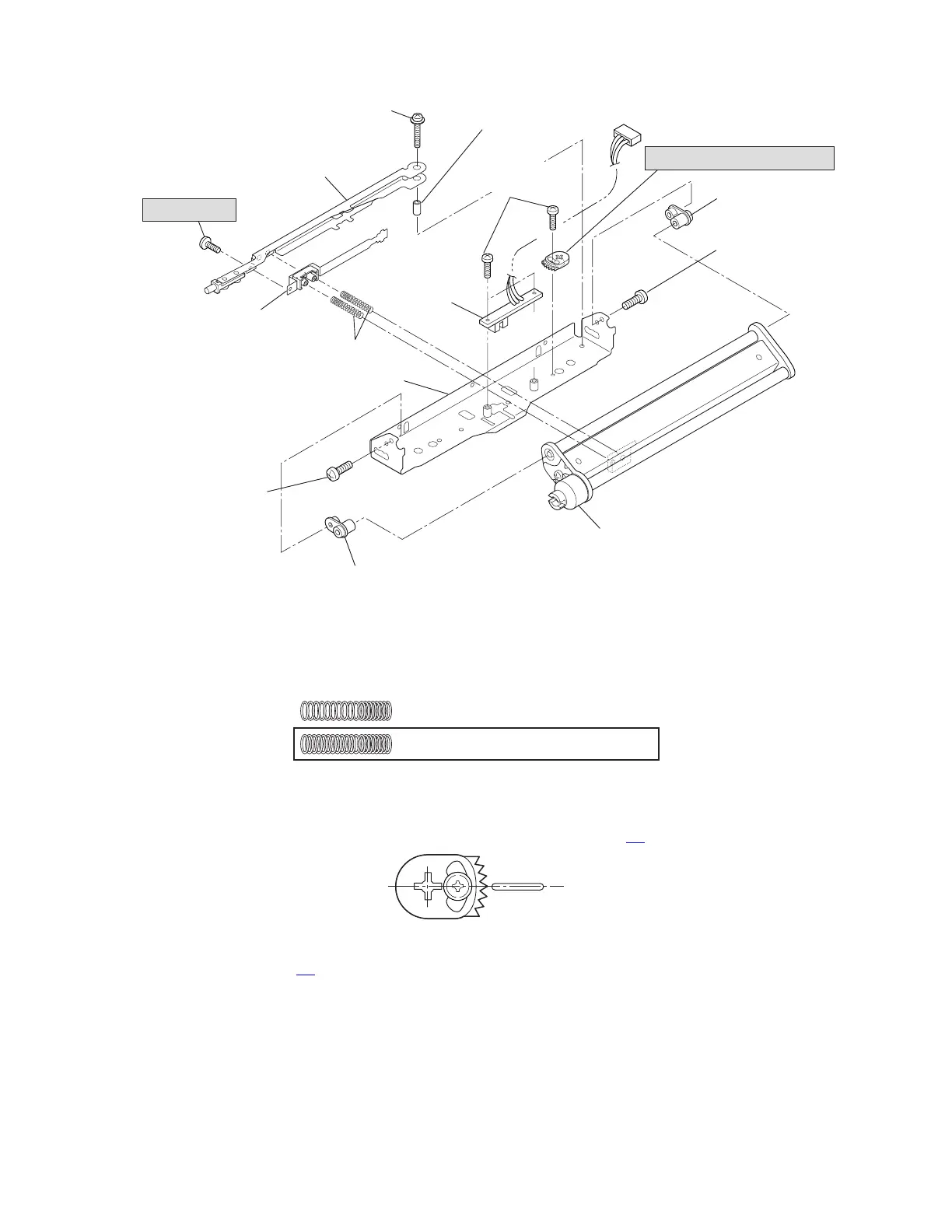

Notes on reassembling:

• Distinguish the Ribbon Tension Spring R (used here) from the Ribbon Tension Spring F (used in

3-5-8 “Ribbon Tension Shaft F SA”). They look like the same, but the number of turns differs.

18 turns (Spring F, Ribbon Tension)

20 turns (Spring R, Ribbon Tension)

• When assembling the Tension Base Adjust Cam, adjust its position as shown in the figure to set

it at the mechanical center. Then, perform adjustment according to 3.6.2-(2-1) “Tension base

adjust cam position adjustment (For service personnel)” on page 3-

47.

• When assembling the tension adjust screw (PH, M1.7x4), perform 3-6-3 “Ribbon Tension

Adjustment” on page 3-

52.

Loading...

Loading...