750-392

CBEX-DE

1-9

Component Locations

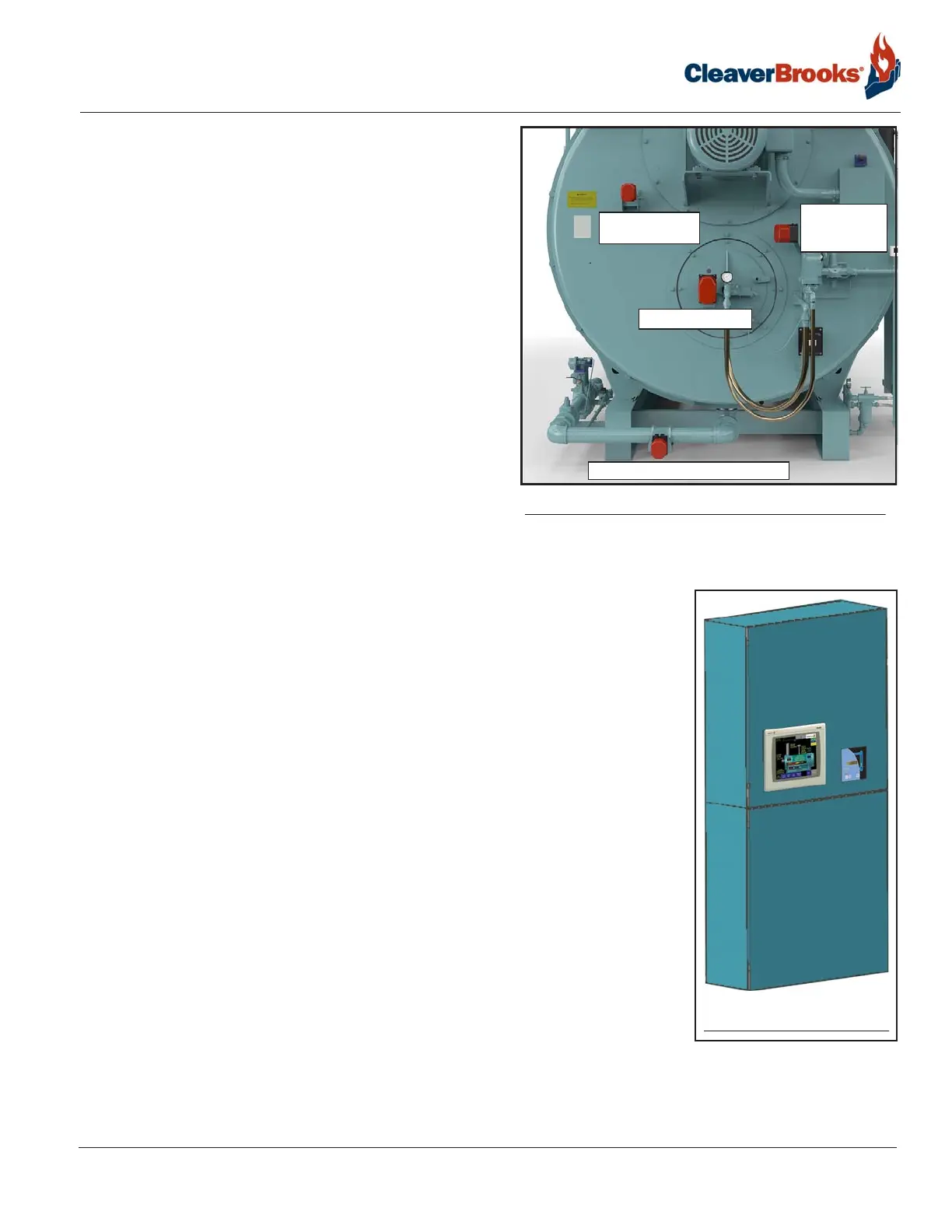

1.2.7 — Actuators

Individual actuators for fuel, air, and FGR are part of the

standard parallel positioning combustion control system,

and are positioned via Modbus signal from the Hawk con-

trol system.

Actuators are connected in series with the air damper actu-

ator last in the sequence. Actuators may use quick discon-

nect cables or may be hard wired depending on the

installation.

For actuator setup and configuration information as well as

combustion setup procedures, see the appropriate Hawk

controls manual.

A single-point positioning linkage system is available for

700/800 HP boilers.

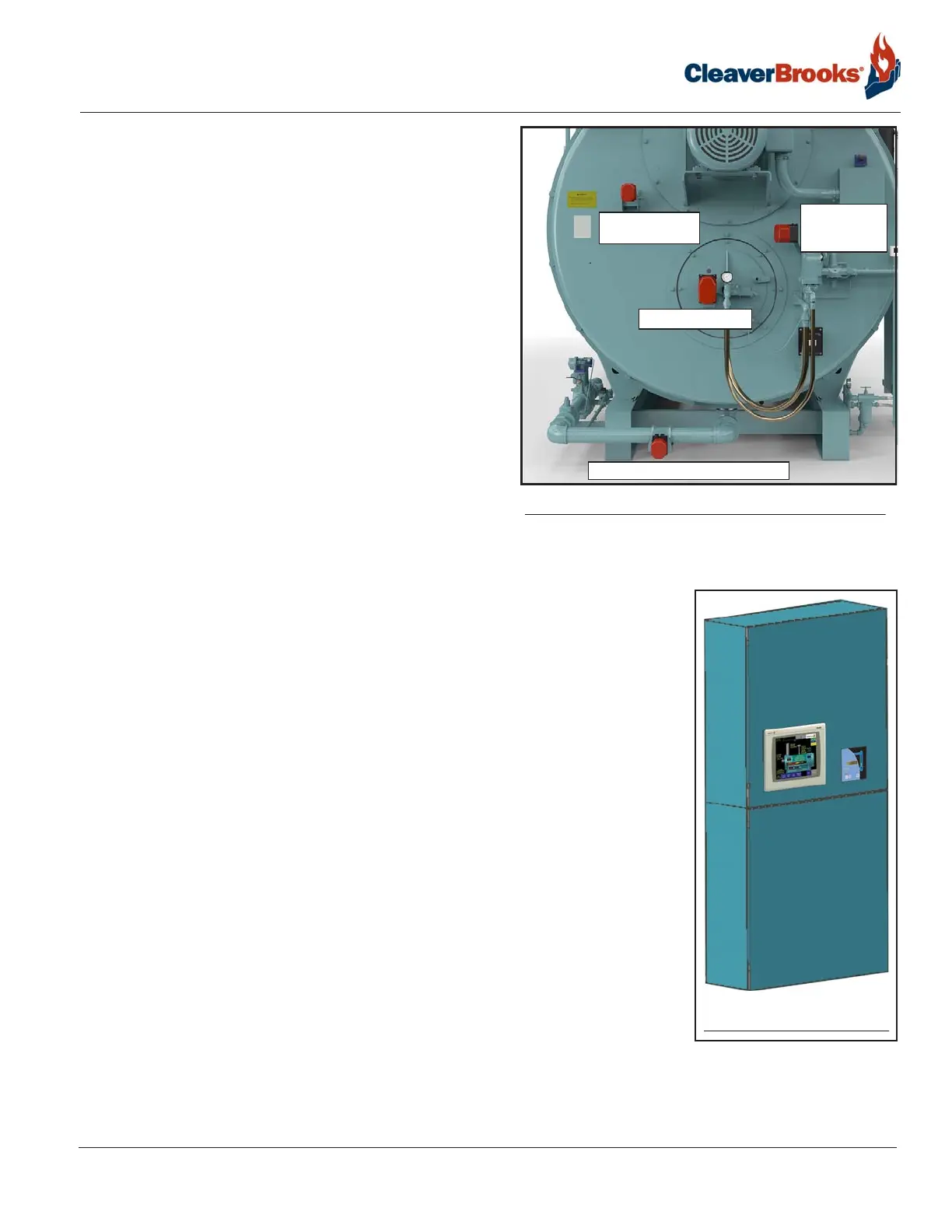

1.2.8 — Control Panel

A common enclosure houses both the control panel and the electrical entrance

panel. The upper and lower sections are divided by a partition with a separate

hinged door for each section.

The upper section (low voltage) houses the boiler control system, including the PLC

and associated modules, the flame safeguard, the Hawk HMI touch screen, and the

LevelMaster panel.

External switches and indicator lights can vary according to options selected. A typ-

ical configuration will include switches for:

• FSG reset

• ALWCO reset

• Burner switch

• Fuel selector switch

The standard control system is the Cleaver-Brooks Hawk 1000, which includes a

4” touch screen.

The optional Hawk 4000 features a 7” touch screen, with a 10” screen optional.

The principal components of the HAWK 1000 are the Programmable Logic Control-

ler (PLC), touch screen Human Machine Interface (HMI), and the Flame Safety

Control. The system also includes 24VDC power supplies and various relays and circuit breakers.

FUEL 1 (GAS BUTTERFLY VALVE)

FUEL 2

(FUEL OIL

CONTROLLER)

FLUE GAS

RECIRCULATION

COMBUSTION AIR

FIGURE 1-11. Actuators

FIGURE 1-12. Control/

entrance panel

Loading...

Loading...