35

Entering the wrong tool number (or even entering a non-existent or empty tool holder number) may

damage your machine and/or cause it to fail.

When you command the machine to measure a tool, it will return whatever tool is currently on

the spindle to its original place first, then proceed to measuring. The machine with the new

tool will then go down to the tool measuring device three times to take the measurements.

This next part is for informational purposes only. Changing the default values may cause your

machine to fail.

See the Step-by-Step chapter at the end of this manual for Measuring Larger Tools.

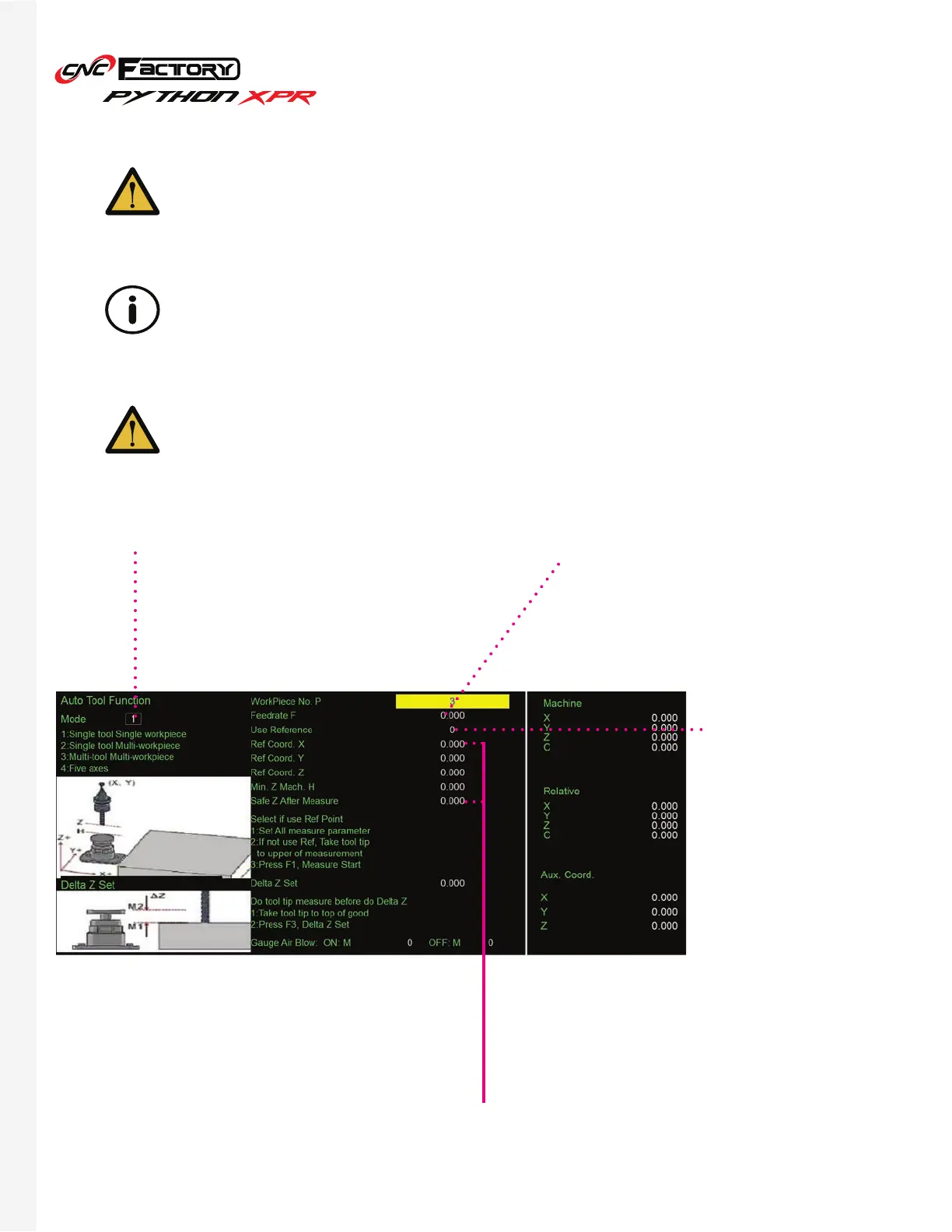

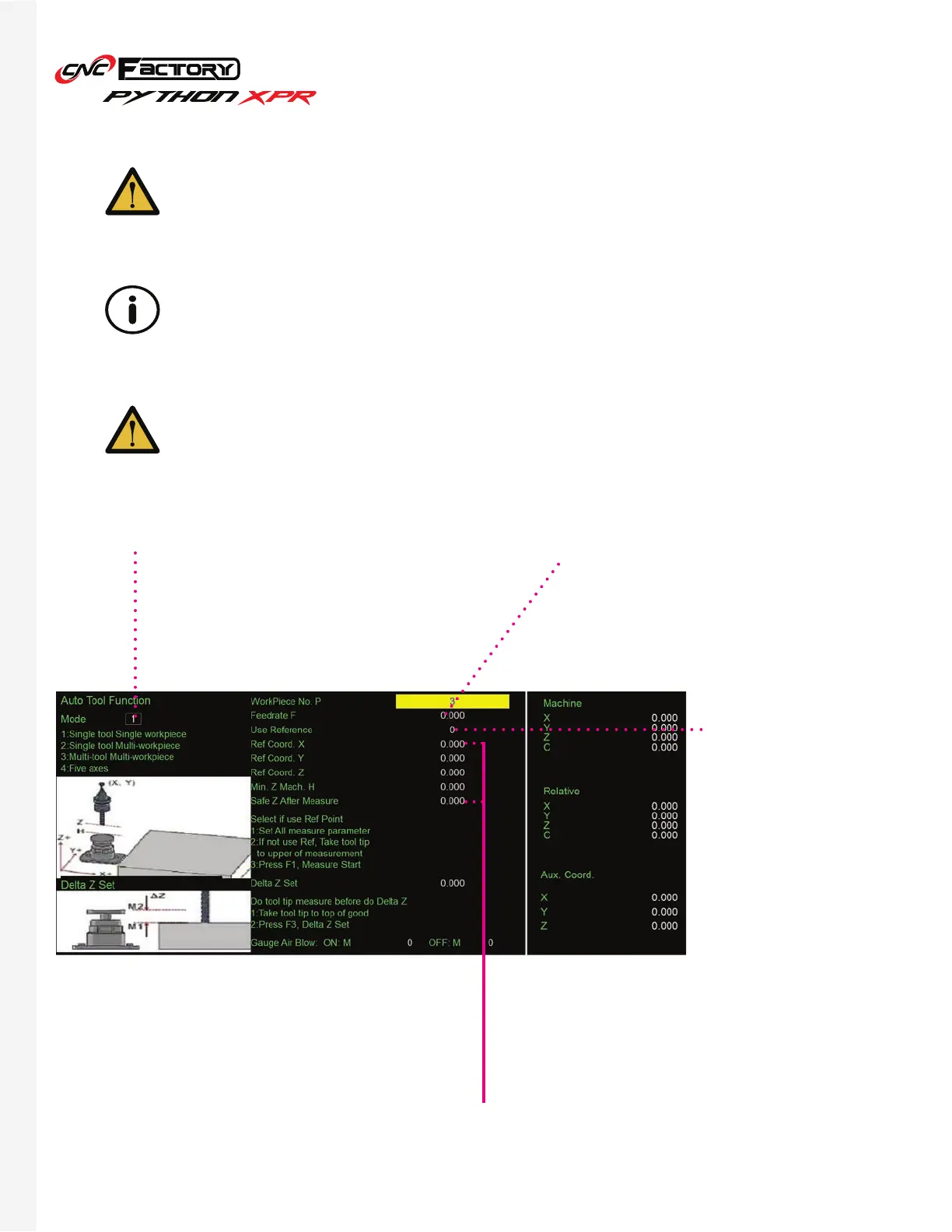

Mode Feedrate F

Use Reference

Reference Coordinates

You router should always be in Mode 3:

Multi-tool, multi-workpiece.

Speed the machine will be moving

as it goes through the tool change in

mm/min.

Grants or denies

permission to use the

succeeding reference

coordinate values. “1”

means “true” or allows

you to use the reference.

“0” means “false” or does

not allow you to use the

reference.

Identifies the location of/

directional limits for your tool

measuring device.

Loading...

Loading...