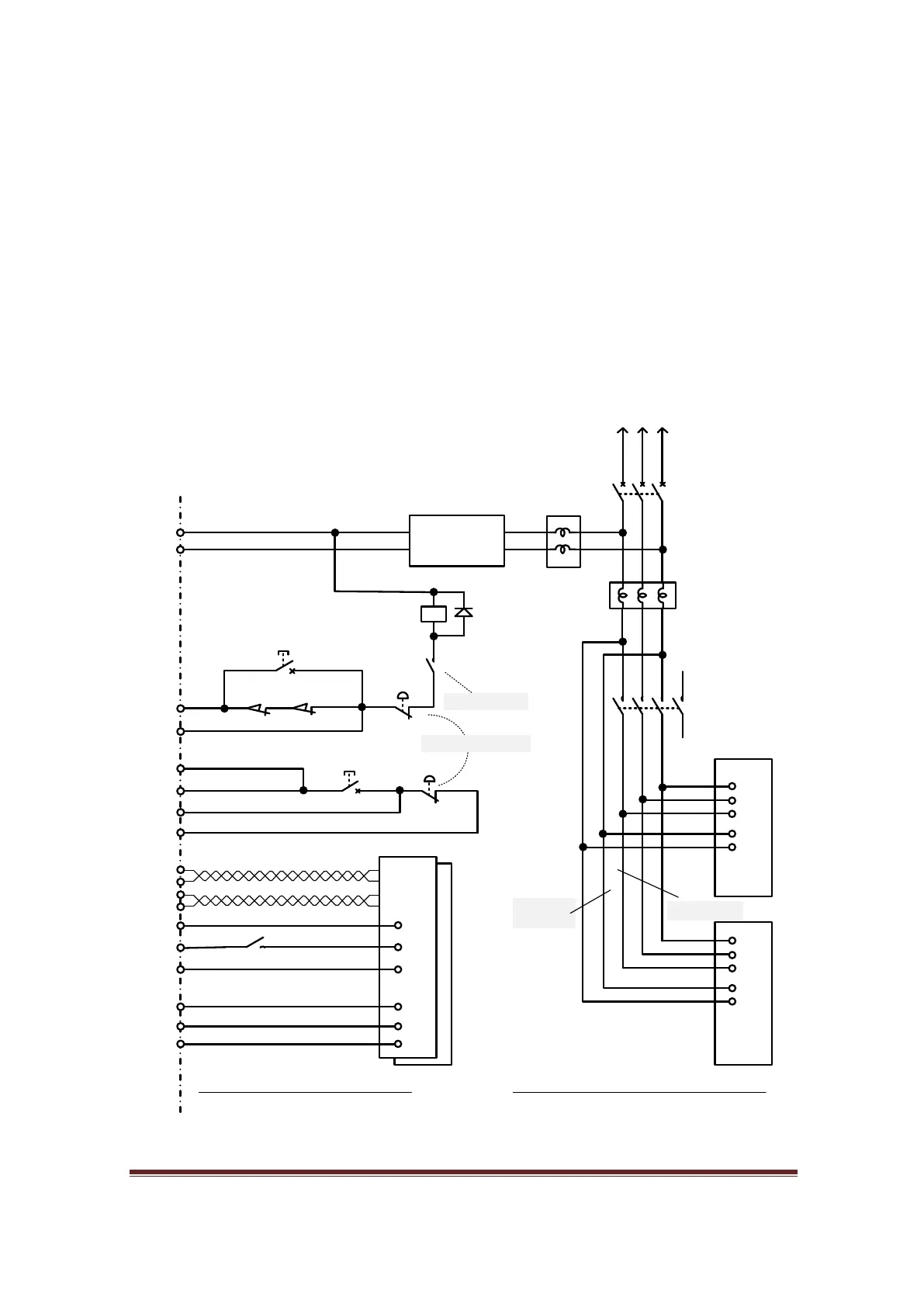

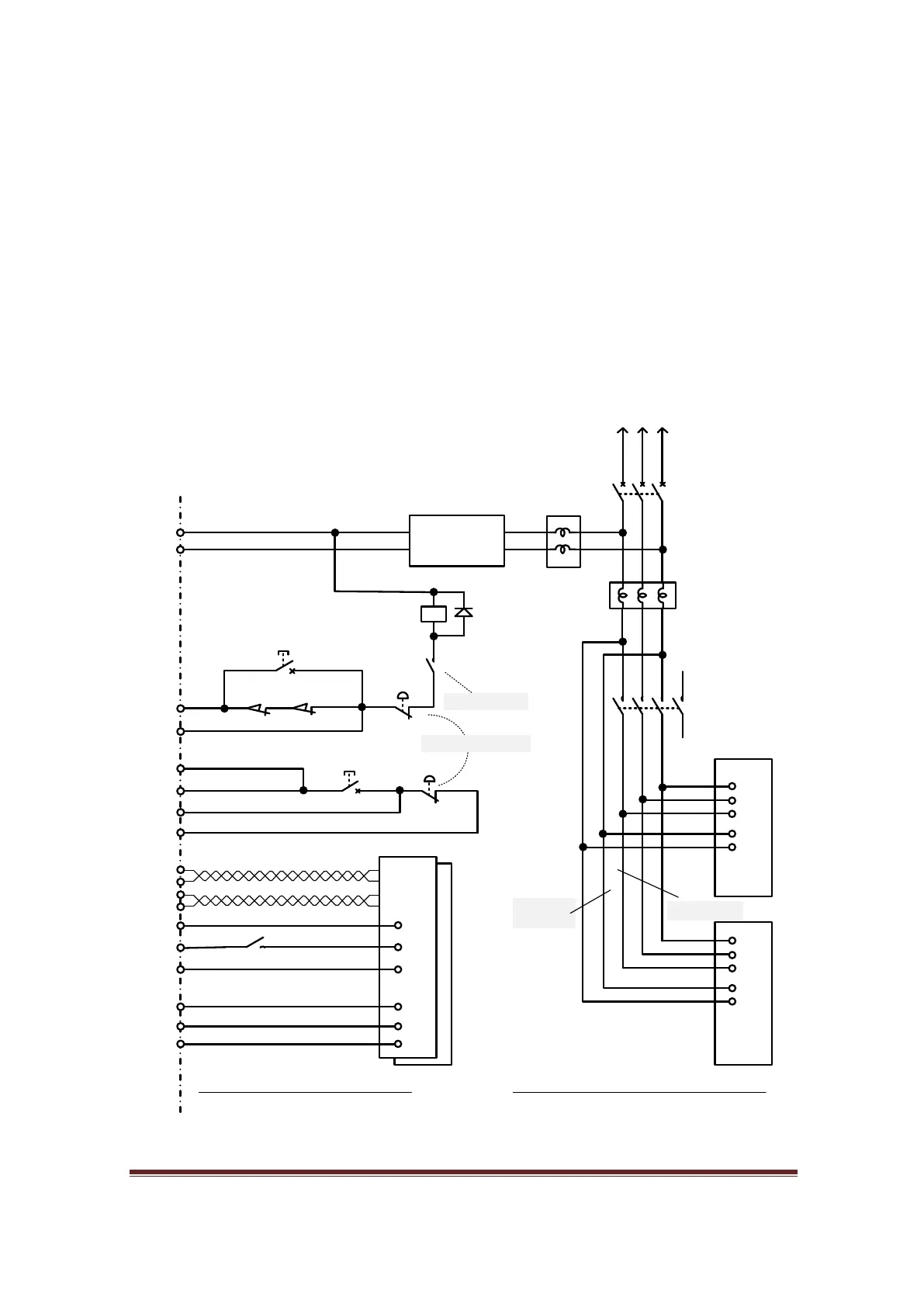

Safety Circuit 2

Safety circuit 2 is more for the user who prefers not to rely on electronics for safety and would

prefer the option of disengaging power from the drives or hazardous devices by the use of

unintelligent components, such as limit switches, the Estop button or a magnetic contactor.

In a situation where a motor runs out of control, being caused either by electromagnetic

interference or even human error, a well-designed system should be able to halt the machine

by the use of limit switches alone or by hitting the Estop button.

However, in normal circumstance, the MB3 with an external circuit and connection to a

computer should work well together. In some drive connections you may need to implement

the use of timer relays to handle an “Under Voltage” error.

PANASONIC MINAS-

A

M1

24V

NO2 (Y214)

E-Stop.2

Step command

Series of limit switches

0V

X115 (Limit signal)

M1

PANASONIC MINAS-A

PANASONIC MINAS-A

MB3 Board

Servo Drive

Power Cicuit

Noise Filter

Circuit

Breaker

Magnetic

Contactor

1 body, 2 contacts

On board relay

1N2004

Control

power

Main power

0V

24V

24V

0V

OVR (safety override)

X110 (Reset signal)

E-Stop.1

0V

X203 (E-Stop signal)

Reset

M1

Servo On

Alarm clear

Y316

0V

24V

24V

Fault (Drive2)

0V

X209 (Fault input)

X210 (Fault input)

Fault (Drive1)

Direction command

External Circuit

Limit override

Servo Drive

Control circuit

Noise Filter

24Vdc

Power supply

To main power

1ph or 3ph

Figure 82, Safety Circuit 2

1. Make X203, X209, and X210 as inputs of safety circuit

by soldering their bridges underneath of MB3 board.

Then assign X202 as the E-Stop input.

2.Assign X115 as Limit input

3.Assign X110 as OEM Trigger, Then assign “Reset OEM

code” or 1021 to System hotkey > External button.

4. Assign Y214, Y316 as Enable1, Enable2 respectively.

www.CNCRoom.com Page 55

Loading...

Loading...