Technical Manual CODEL

22

Maintenance

The Tunnel Tech 700 Series system is designed for low maintenance. The sensors utilise the latest

microprocessor technology. The AQM sensor uses an infrared source that has a life expectancy of

over 3 years.

Routine Maintenance

VIS

6.1.1.1. Mechanical Check

Every 6 months - clean the optical surfaces of the AQM sensor and the reflector unit.

Access to the lenses is obtained by removing the sight tube on the front of the sensor mounting

bracket; this is done by removing the retaining bolts securing the tube to the flange. Removal of the

tube reveals the two lenses. Clean the lenses with a soft dry cloth and replace the sight tube. There

should be no need to re-align the sensor.

Access to the reflector is gained by removing the sight tube on the front of the reflector mounting

bracket. This is done by removing the retaining bolts securing the tube to the flange to reveal the

mirror on the inside of the cover plate. Clean the mirror with a soft dry cloth and replace the sight

tube. There should be no need to re-align the reflector.

The next stage of the mechanical check is to check detector levels. By following the steps below,

observe the detector levels to see if they correspond with the required levels of 10000 +/- 2000.

6.1.1.2. Press to return to the main display.

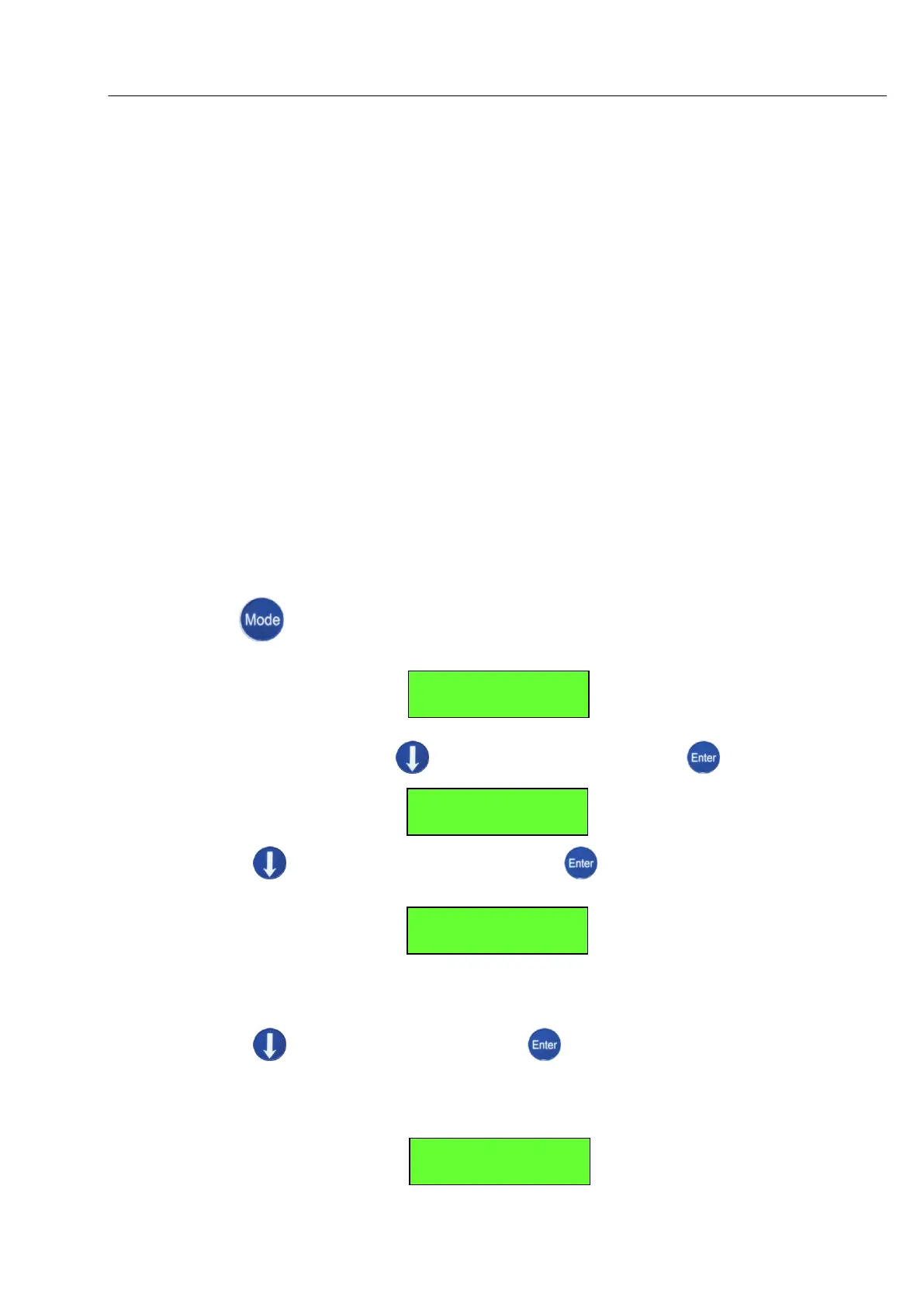

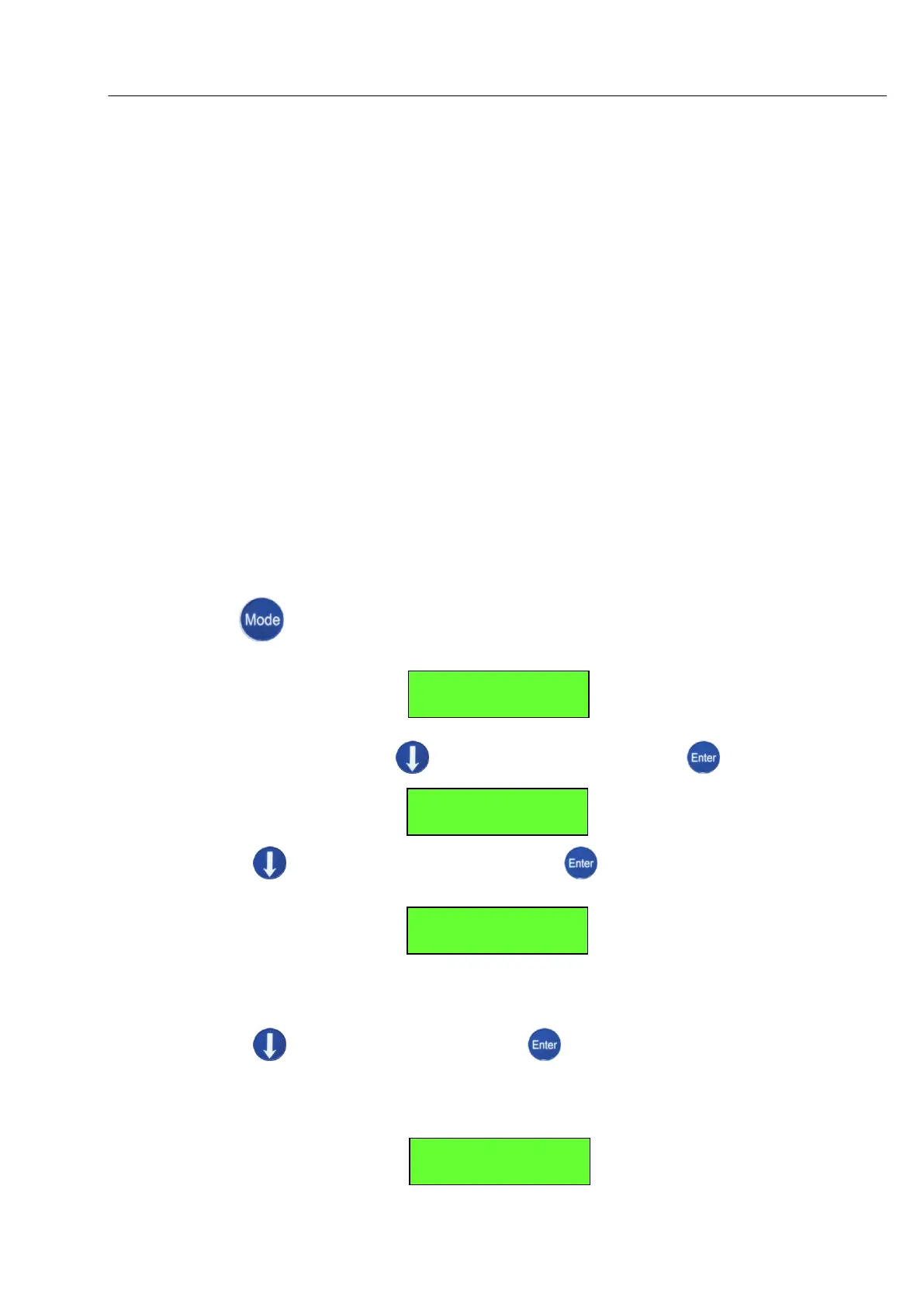

From the main display press to reach Diagnostics. Press to access

Diagnostic data.

.

6.1.1.3. Use the key to reach Vis Diag, and press to access.

6.1.1.4. Use the to reach Vis DRx, and press to access.

6.1.1.5. Vis DRx: Observe DRx Smoothed value while adjusting the optical alignment of the

instrument until this value has reached a plateau.

1. Meas - 09:24:29

CO: 21 ppm

3. DIAGNOSTICS

3.5. VIS Diag

Loading...

Loading...