8 Technical appendix

8.1 Adjusting the predispensing

Predispensing is the length by which the label is pulled forward after detection of the leading edge of

the label. Its value can be entered in 0.1 mm steps. The predispensing is normally used to optimize

the label position. Adjust it so, that the label is sticked to the goods at the time, when it has the same

speed as the goods. Only so the label position on the goods is always exact and does not vary.

If a new value is entered exceeding the old one, the label is pulled forward correspondingly.

But if the new value exceeds the old one, predispensing will be corrected only after one label has be-

en dispensed.

If the entered predispensing length exceeds the label length, a malfunction of the labeller may result

since the gap between labels is measured at a wrong time.

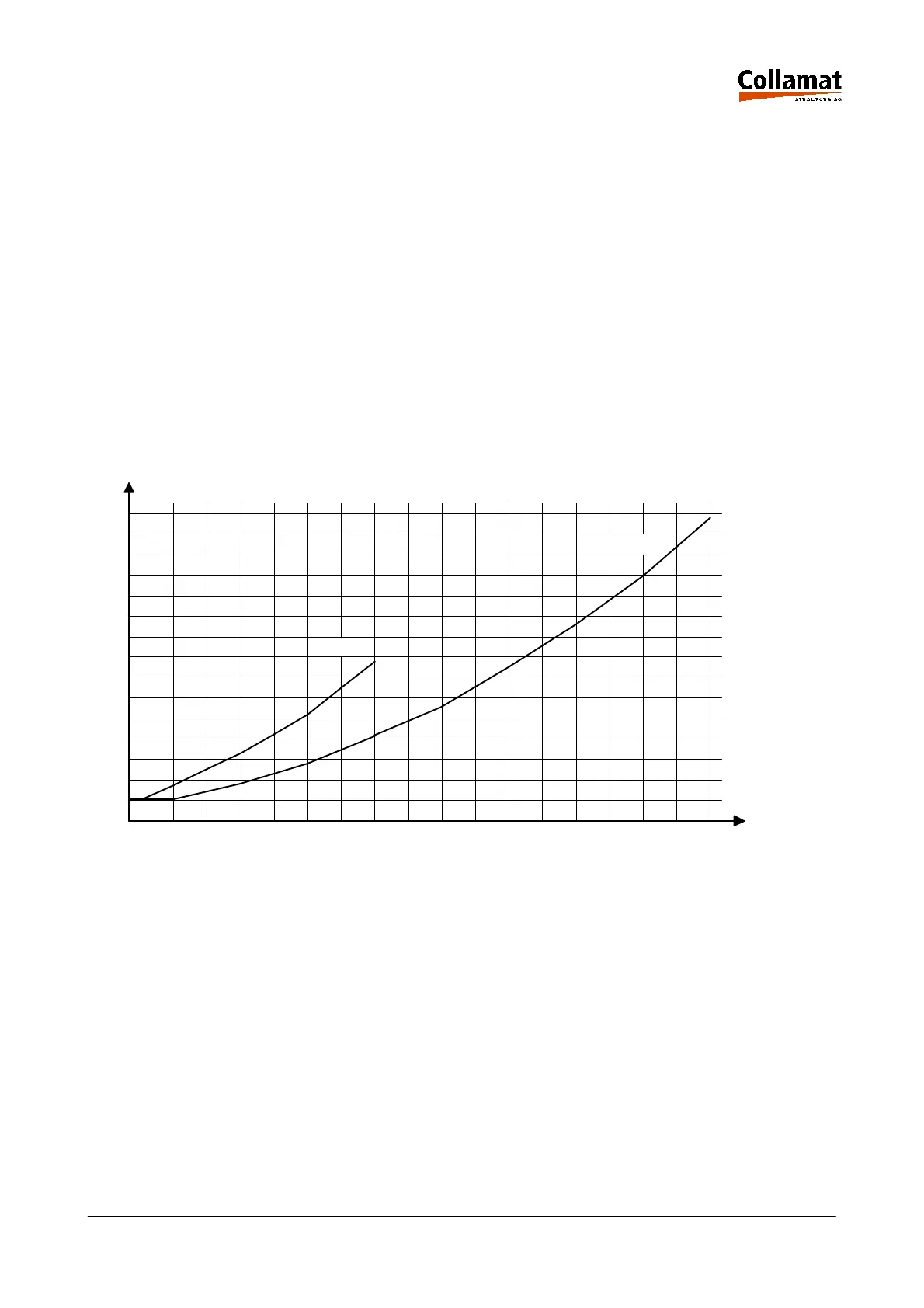

The minimum predispensing depends on the maximum labelling speed. The labeller needs more time

at high labelling speed to brake the label after having detected its leading edge. The following diagram

shows predispensing vs. labelling speed:

Predispensing [mm]

Labelling speed [m/min]

Diagram predispensing vs. labelling speed.

C9100

C8600

0 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

5999.530-01E 14.01.2004 CSWM 4 42

Loading...

Loading...