Maintenance

124

C3M2-OM-EN-02

6. Enter the area between the left-hand and right-hand platforms behind the mast.

Ensure all surfaces are clean and dry and take great care to avoid slipping!

7. Close the shut-off valve (A) on the back of the hydraulic tank.

8. Clean the area around the suction filter (B) thoroughly before removing the used

filter element to prevent any contamination from entering the hydraulic system.

9. Position a suitable container under the used filter element to collect any

escaping oil.

10. Unscrew and remove the used filter element. Use a filter wrench if required.

11. Check the sealing surfaces and threads on the filter mount and on the new filter

element and clean if necessary.

12. Apply a thin film of clean hydraulic oil to the O-ring on a new suction filter

element.

13. Screw the new filter element on to the filter mount until it is hand tight only. DO

NOT over tighten the filter element. Use a genuine OEM component.

14. Open the shut-off valve on the back of the hydraulic tank before starting the

engine.

15. Start the engine and check around the suction filter for leaks. Repeat the check

when the hydraulic oil has reached operating temperature.

16. Top up the hydraulic oil if necessary (see section 5.6 ‘Checking Hydraulic Oil

Level’ on page 72).

17. Dispose of waste oil and used filter elements in compliance with local

regulations.

18. Clean up any oil spills immediately.

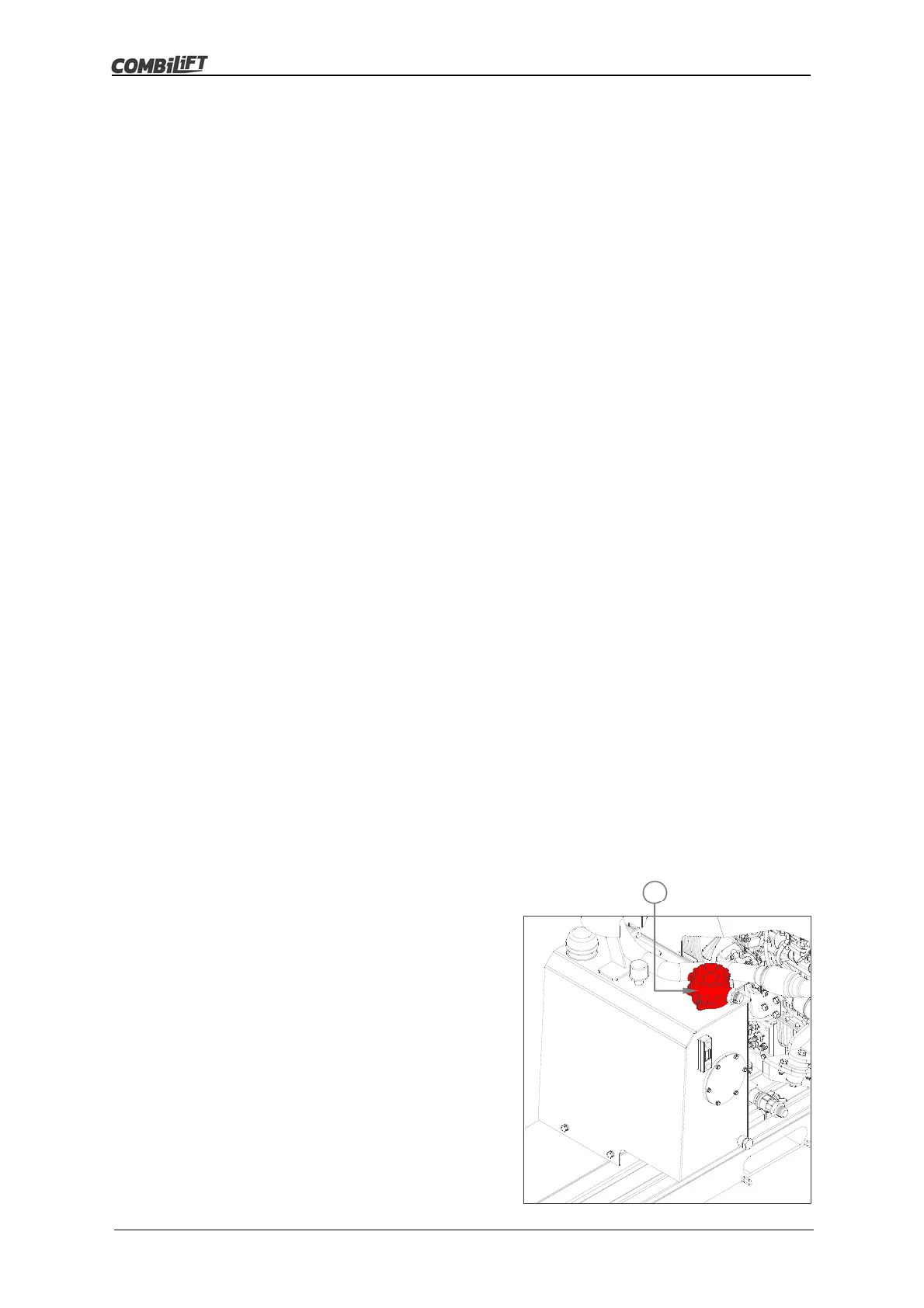

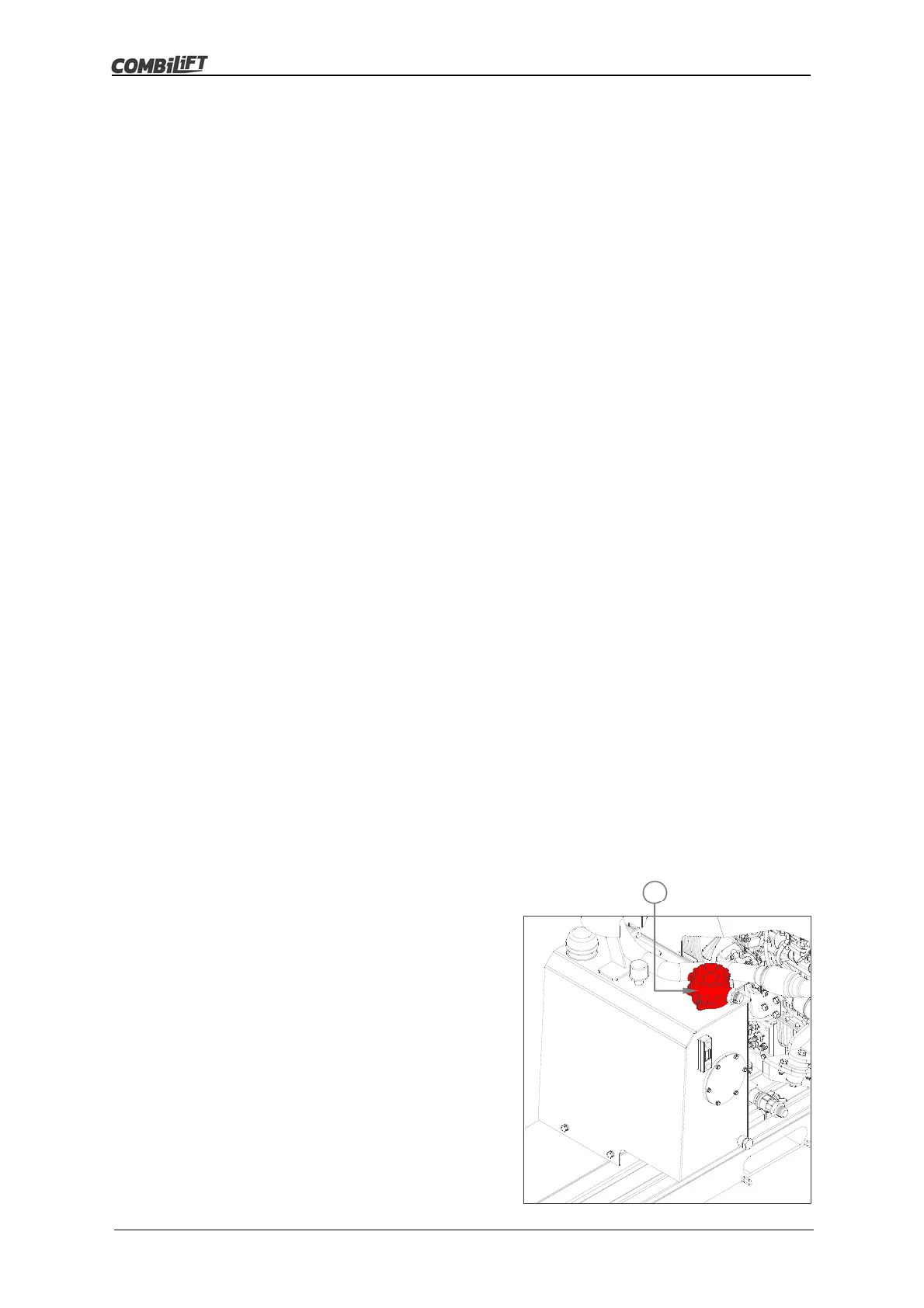

Return Filter

The hydraulic oil return filter is mounted on the top of the hydraulic tank. It filters the oil

as it is returned from the valve chest to the tank.

The return filter element must be replaced after the first 100 hours of operation and

then at regular intervals in accordance with the maintenance schedule.

To change the return filter element:

1. Stop the truck in a designated service

area.

2. Lower the mast fully and tilt the mast

forward fully.

3. Turn the ignition key switch to the ‘0’ off

position, then remove the key.

4. Ensure all parts concerned are cool

enough to touch, otherwise wear heat

resistant gloves before proceeding.

5. Clean and dry the return filter (A) and

the surrounding area thoroughly to

prevent any contamination from entering

the hydraulic system.

A

Loading...

Loading...