Maintenance

136

C3M2-OM-EN-02

X X

Note

The wear pads must only be in light contact with the channels to allow the

carriage to travel freely. Do not over tighten the adjustment bolts as the

force between the wear pads and the channel will cause the carriage to

stick. Maximum torque of the bolts should not exceed 25Nm (18.5ft.lb).

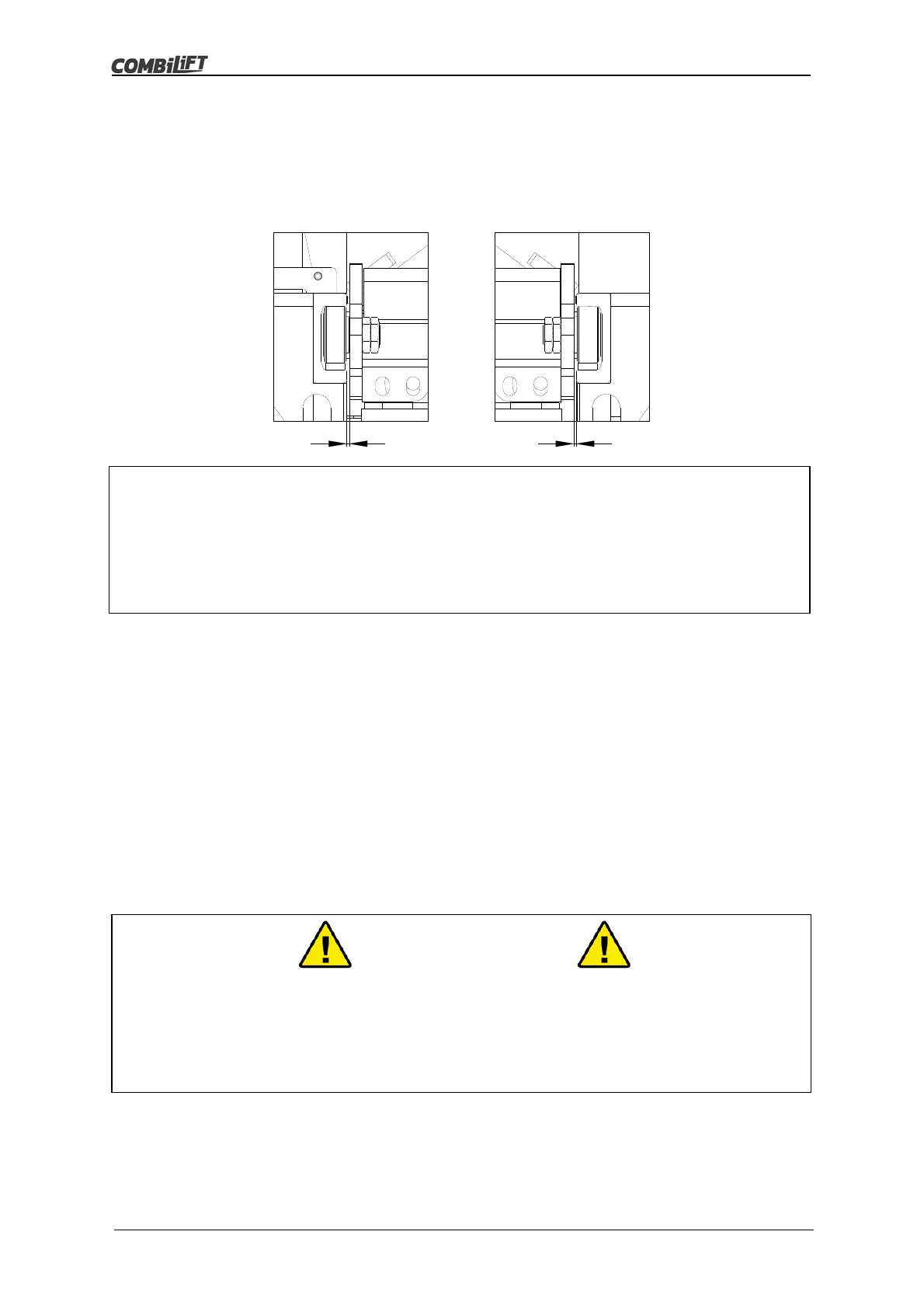

4. Measure the distance (x) between the mast carriage side plate and the channel

at the front of the machine on both sides of the truck. The distance (x) must be

equal on both sides. Turn the front wear pad adjustment bolts clockwise to push

the wear pads up against the channels. Adjust the wear pads until the distance

(x) is equal on both sides.

5. Adjust the wear pads on the rear as described in point 4.

6. Check that the vertical faces of the channels where the wear pads run are clean

and adequately lubricated. Operate the reach function to move the mast in and

out several times through the full extent of its travel.

7. Check the torque of all the adjustment bolts. The torque must not exceed 25Nm

(18.5ft.lb).

8. Tighten all the locking nuts up against the mast carriage side plates to lock the

adjustment bolts in place. Use a spanner to prevent the adjustment bolts from

turning while the locking nuts are being tightened.

6.19 Fork Maintenance

Inspect the forks as required by the pre-use checks and the maintenance schedule.

This section provides details on how to perform a complete fork inspection with the aim

of detecting any damage, failure, deformation, etc., that may impair safe use. Any fork

that bears such a defect must be removed from service.

Warning

Never operate the truck if the forks are damaged. If a defect is found in the

forks or mounting components take the truck out of service until the fork is

repaired or replaced. Report any fork damage to the relevant supervisor

immediately. Failure to follow this warning can cause serious injury or

death.

Loading...

Loading...