Maintenance

96

C3M2-OM-EN-02

Note

All grease points indicated on the grease point chart MUST be greased

every 100 operating hours / 3 months using EP2 Grease.

Note

All wheel nuts should be visually checked daily and torqued every 250

hours

See section 6.6 – ‘Wheel Nut Torque’ on page 100

6.2 Initial Service – Conducted at 100 hours of Operation

The descriptions of work processes contained within this manual are provided only for

fully trained and competent maintenance staff with the necessary skills, knowledge and

experience to carry out the work safely. Follow the operator’s manual for the engine

for more details regarding engine servicing procedures.

To assure proper functioning of the truck, it is required that the first inspection be

performed at 100 operating hours or 3 months (depending on which comes first), after

initial start-up.

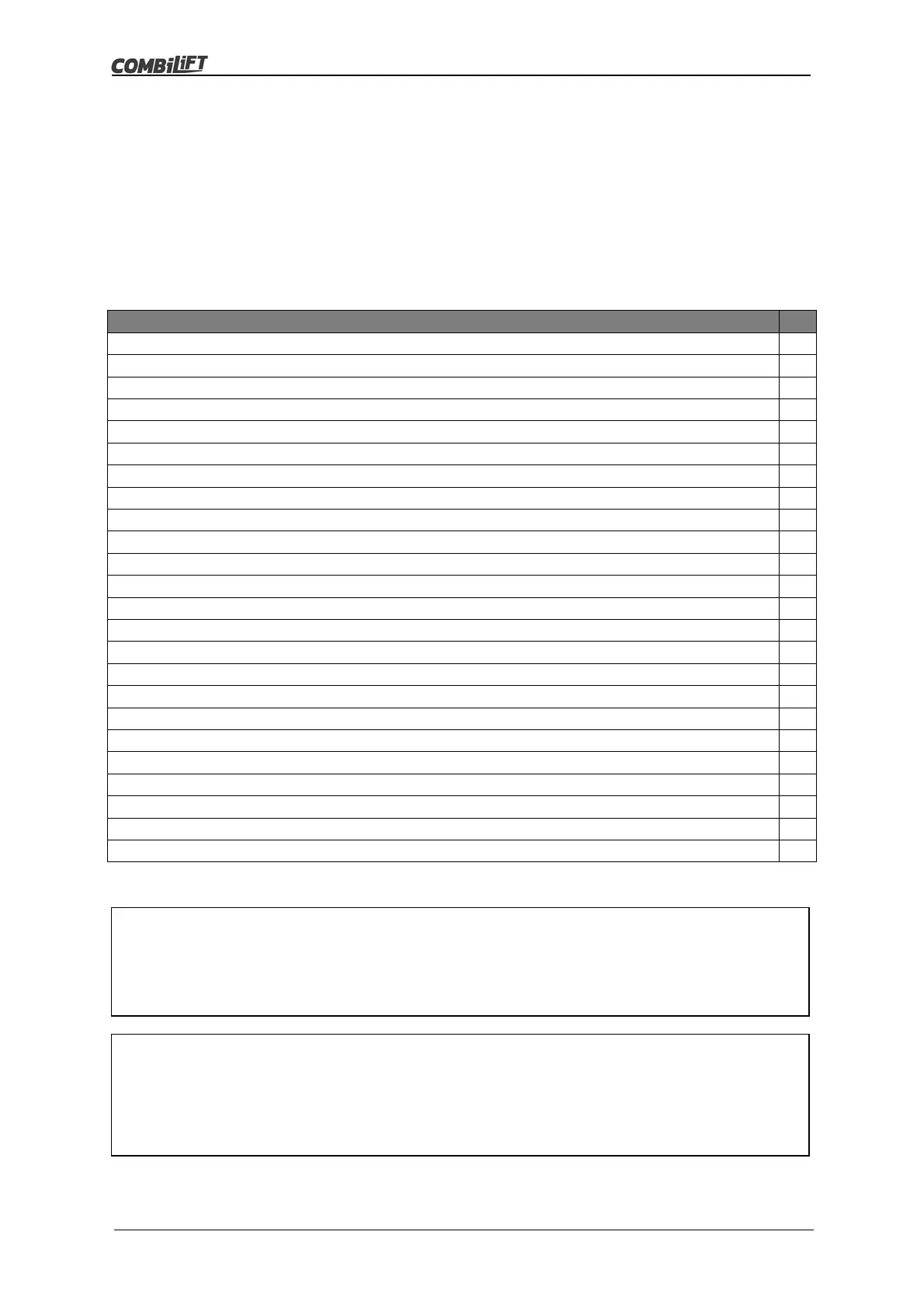

Tasks To Be Performed At 100 Operatin

Hours or 3 months

✔

Check tension and condition of the engine v-belt(s)

Change the hydraulic suction filter element

Change the hydraulic return filter element

Change the engine oil and the engine oil filter element

* Change lock-off valve filter, change in-line cannister filter (if fitted)

Check the hydraulic oil level

Check the coolant level

Check the machine for hydraulic, coolant and fuel leaks

Check the engine air intake filter and clean or replace if necessary

Check the engine air intake hoses and connections for cracks and loose clamps

Check all mast reach carriage bearing lock nuts are tight

Check mast reach carriage wear pads & alignment

Check all bolts, nuts and fittings are present and secure

Check the routing of hydraulic hoses, pipes and wires

Check the chrome rods on all hydraulic cylinders are clean and undamaged

Check the cleanliness of the radiator and hydraulic oil cooler(s)

Check instruments and warning icons on the display console

Check the electrical system, ensure all connections are secure

Check the brakes, steering and the operation of all hydraulic functions

Check all lights (i.e. work lights, road lights & safety lights if fitted)

Check the operator’s cabin & door for structural defects or damage

Check the condition of the tyres

Torque all wheel nuts (see 6.6 Wheel Nut Torque on page 100)

Check mast chains; lubricate and adjust if required

* LPG engine powered trucks only.

Loading...

Loading...