Maintenance

137

C3M2-OM-EN-02

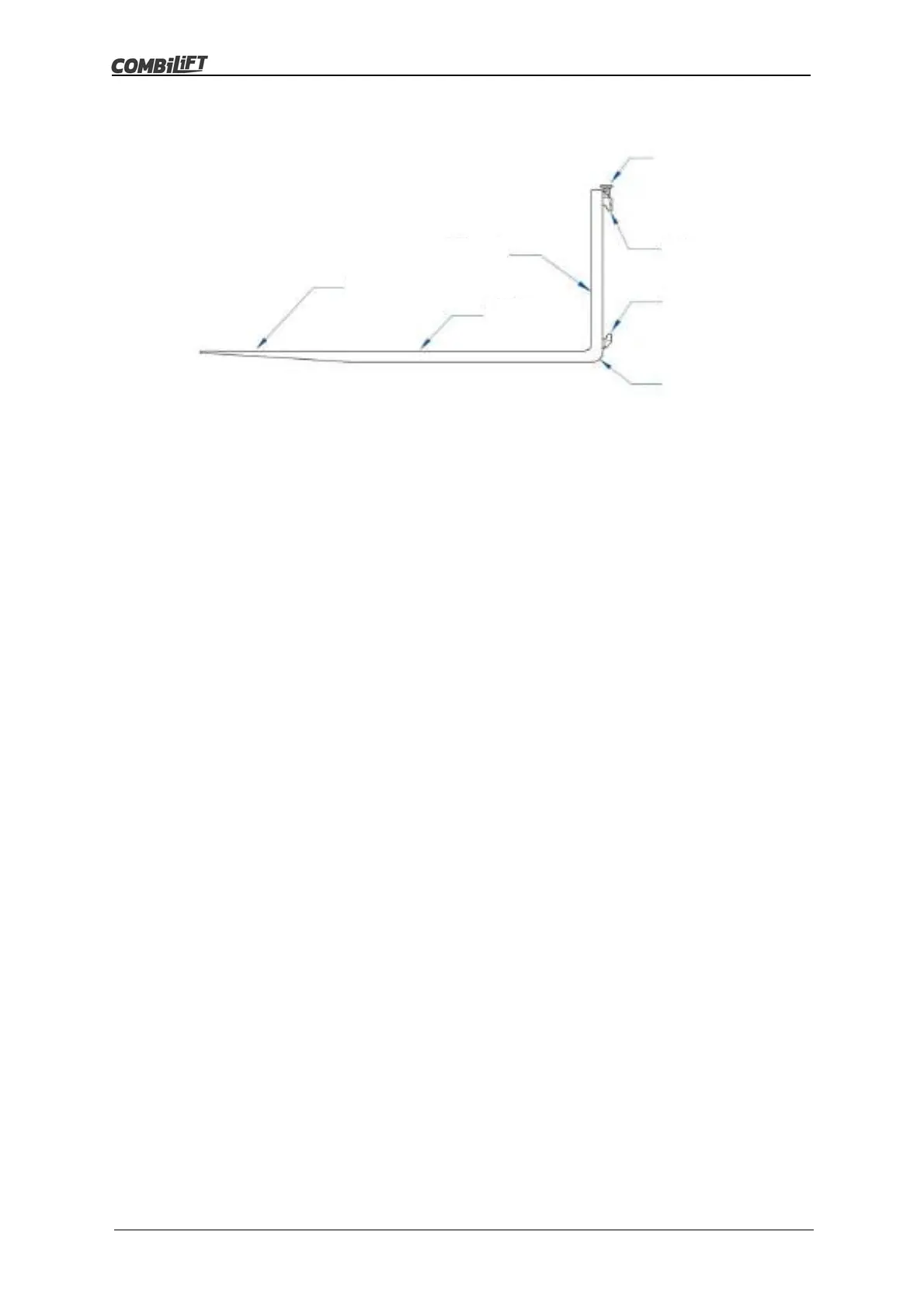

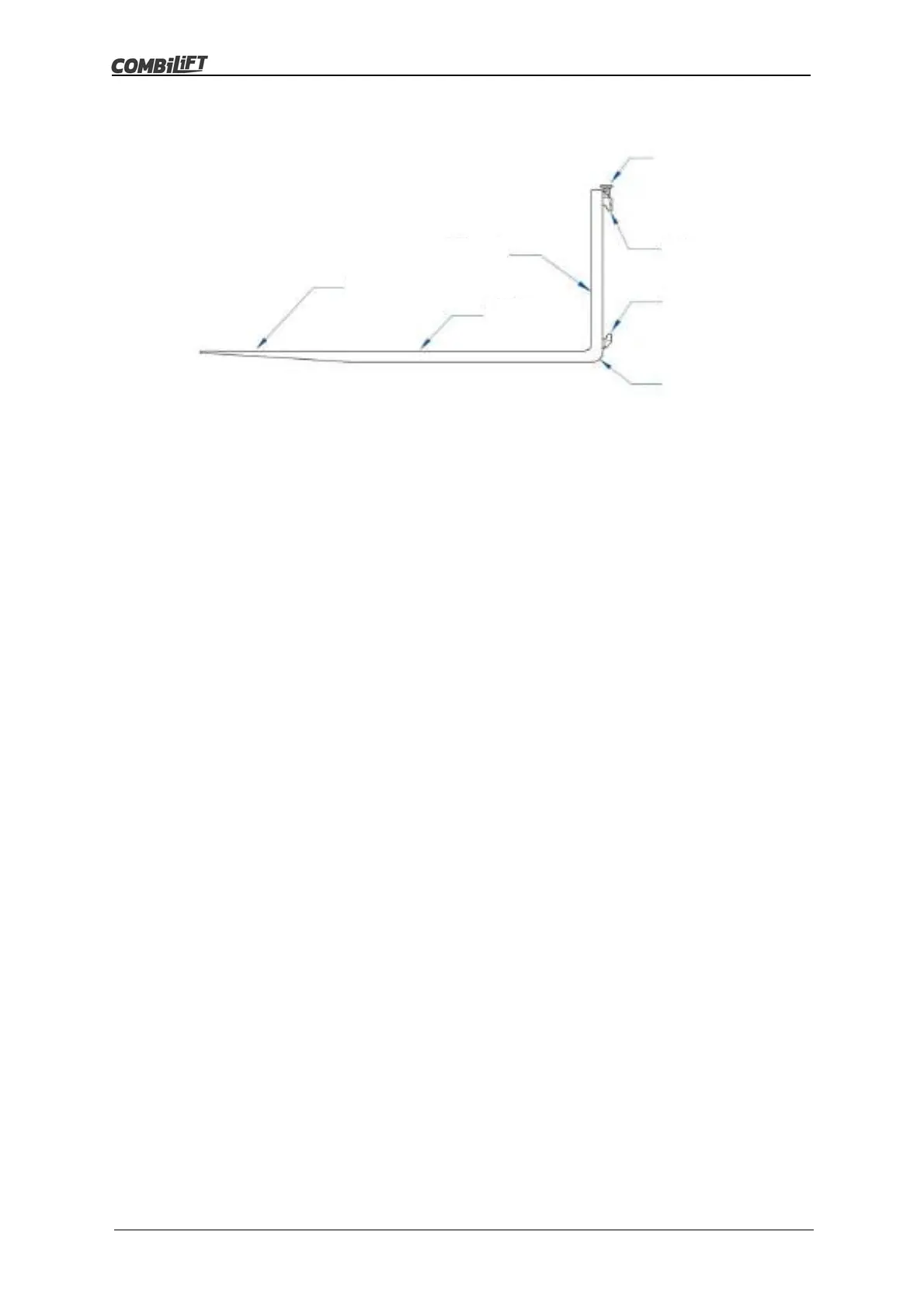

Tip

Shank

Blade

Heel

Positioning

Lock (If Fitted)

Hook

Hook

Fork Overview

Straightness of Blade and Shank

Check the straightness of the upper face of each blade and the front face of each

shank. If the deviation from straightness exceeds 0.5% of the length of the blade and/or

the height of the shank, respectively withdraw the fork from service.

!

Cracks

Visually examine the forks for surface cracks. Pay special attention to:

Fork heel

Welds that attach mounting components to the fork blank

Forks with surface cracks should not be returned to service.

Fork Angle

Check the angle between the front vertical face of each fork and the load face of each

shank. If the deviation exceeds 3° from the original specification withdraw the fork from

service.

Difference in Height between Fork Tips

Check the difference in height between tips of the forks with the forks mounted on the

fork carriage. If the difference in tip heights exceeds 3% of the length of the blade, the

forks should be removed from service.

Positioning Lock (If Applicable)

Check the positioning lock on each fork to make sure it functions properly. If any

problems are noted, repair or replace the fork.

Forks on trucks with optional hydraulic fork positioning do not have positioning locks.

Wear

Two different areas of the fork and fork attachment should be checked for wear.

Fork Blade and Shank – Check each fork blade and shank for wear, pay

special attention to the area surrounding the heel of the fork. If the thickness is

reduced to 90% of the original thickness, remove the fork from service.

Loading...

Loading...