Rev/Rev

Descrizione Modifiche/Change description

Emissione/Emission Approvato/Approval

-

-

Il presente disegno non può essere utilizzato né riprodotto o reso noto a terzi senza autorizzazione della Think Water

This draw cannot be used nor reproduced or given to third parts without the authorisation from Think Water

Scala/Scale

Tolleraza Generale/

General Tollerance

Denominazione/Product name

Progettista/Designer Verifica/Confirm

Codice prodotto/ Product code

Applicazione/Application

N° disegno/N°drawing

• Esecutivo/

Executive

• Sperimentale/

Experimental

Data/Date

N° tavola/N° table

Materiale/Material

1:2

-

2010

-

media 1 di 1

pavan -

Raggi non quotati/

Rays not quoted

±0.05

da/from

0.5

fino a/to

3

Designazione/

Specification

media

Denominazione/

Name

f fine

m

±0.2

±0.1

±0.1±0.1

±0.05

±0.3 ±0.5

±0.15 ±0.2

±0.8 ±1.2

±0.3 ±0.5

da/from

0.5

fino a /to

3

±0.2

1)

±0.5

±1

1) Per le dimensioni nominali minori di 0.5 [mm], gli scostamenti devono essere indicati vicino alle dimensioni nominali

1) If the nominal dimension is less 0.5 [mm] the limit of tollerance must be written near the nominal dimension

Classe di tolleranza/

Tolerance class

Tab. 1: Scostamenti limite [mm] ammessi per dimensioni lineari,

esclusi smussi e raccordi per eliminazione di spigoli (vedi Tab. 2)/

Limit of tolerance [mm] for linear dimension, without groove and

half-round fillet to erase edge

1)

Tab. 3: Scostamenti limite per dimensioni

angolari in funzione dei campi di lunghezza

[mm] del lato più corto dell'angolo/ Limit of

tolerance for angle, reference to the shorter

side of the angle [mm]

±1° ±0°30' ±0°20' ±0°10' ±0°5'

da/from

3

fino a/to

6

da/from

6

fino a/to

30

da/from

30

fino a/to

120

da/from

120

fino a/to

400

da/from

400

fino a/to

1000

da/from

1000

fino a/to

2000

da/from

3

fino a /to

6

oltre/over

6

Tab. 2: Scostamenti limite [mm] per

smussi e raccordi per eliminazione di

spigoli/ Limit of tolerance [mm] for groove

and half-round fillet to erase edge

da/from

0

fino a /to

10

da/from

10

fino a /to

50

da/from

50

fino a /to

120

da/from

120

fino a /to

400

oltre/over

4000

-

- -

-

-

-

-

-

-

-

-

- -

-

A3

UNI EN ISO 22768

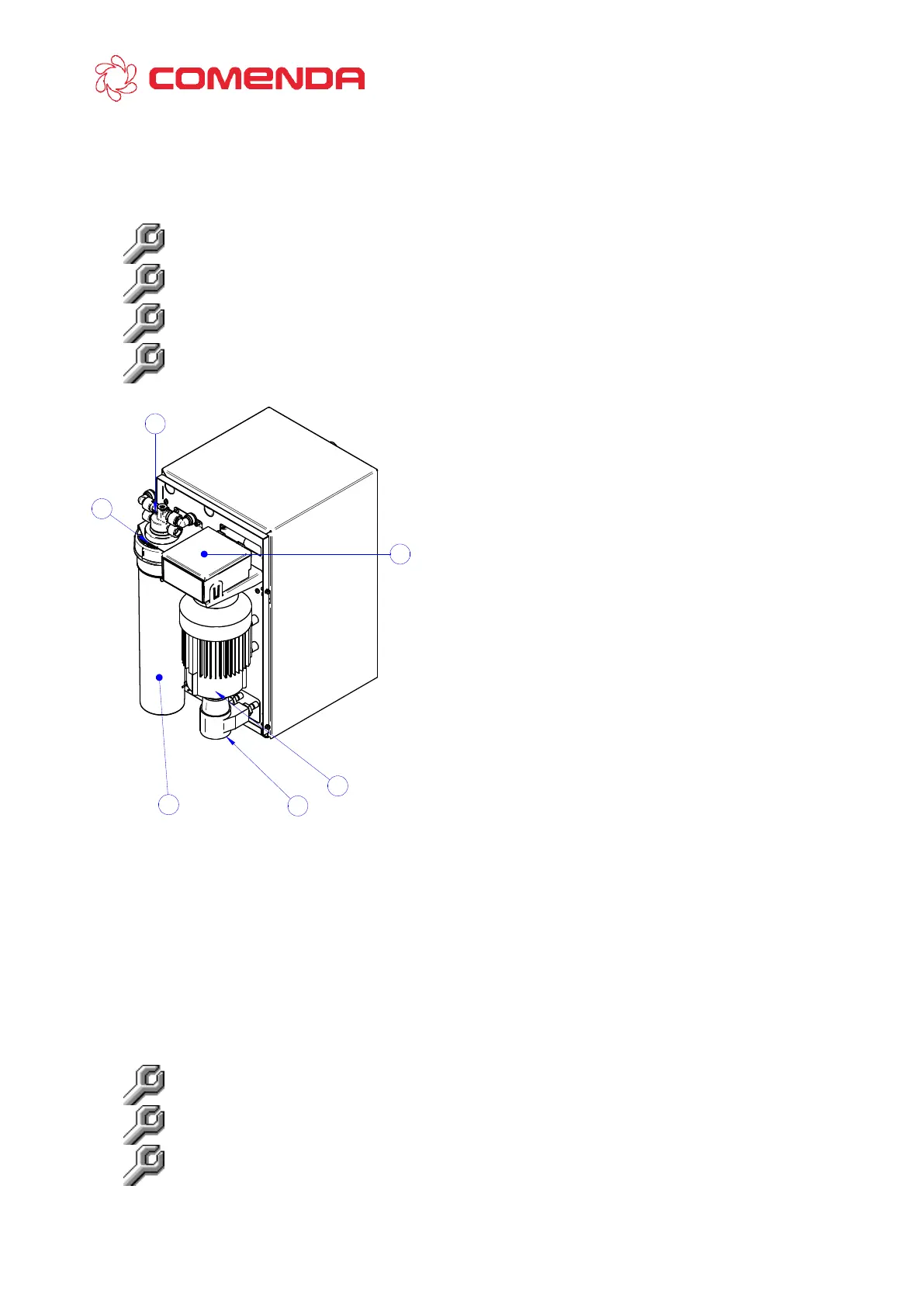

4

2

3

1

5

6

elettronica.

Loading...

Loading...