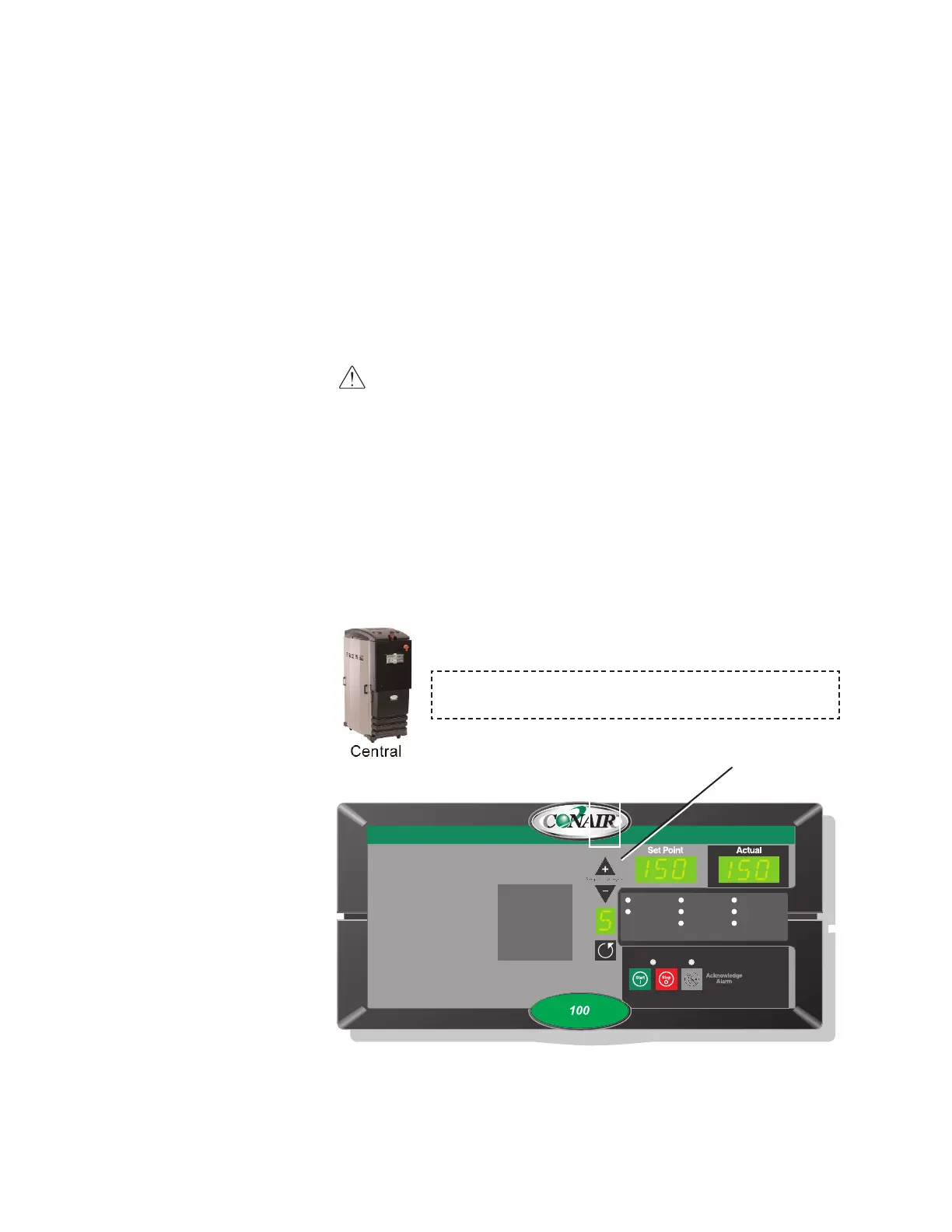

Checking for Proper Air Flow

This procedure is needed on W-50 through 100 models if the phase detection

option was not ordered with the dryer.

CAUTION: This procedure must be performed before the dryer’s air hoses are con-

nected to the hopper. Performing this step after the air hoses are connected could

cause damage to the dryer if the air flow direction is incorrect due to improper

phase connection. Material from the hopper can be pulled into the process

heater, causing permanent damage.

1 Turn on the main power to the dryer. Make sure the dryer’s disconnect dial is

in the ON position. This powers up the control and the display lights will

illuminate.

2 Set the drying temperature. Press Setpoint Adjust (+) or (-) buttons to set the

drying temperature to a low setpoint of 150ºF {66ºC}.

Shutdown Alarms

A1 Process High Temp

A2 Process Loop Break

A3 Process Heater High Temp

A4 Regen Heater High Temp

A7 Return Air High Temp

A49 Process Protection High Temp

A53 Process Blower Overload

A55 Wheel Rotation Failure

Passive Alarms

P1 Process Temp Deviation

P3 Regen Temp Deviation

P5 Return Air Mid High Temp

P17 MDC Conveying Demand

1 Process Temp.

2 Regen. Temp.

3 Return Air Temp.

4 Auto Start

5 Load Time (MDC)

6 Activate Setback Temp.

7 Setback Temp.(Process)

8 Dewpoint

Auto Start

Dewpoint Control

Set-Back Temp.

Regen. Blower

Regen. Heater

Conveying Blower

Process Blower

Process Heater

3-8 l Installation

When configured as a central dryer, the drying temperature can

not be set since there is no process heater in the system.

Setpoint Adjust

Buttons

IMPORTANT: This step must be performed before the dryer’s air hoses are connected to

the hopper or before loading material into the hopper.

Loading...

Loading...