7. Menu 74 Parameters ALSPA PROFIBUS Field Bus Coupler

Page 7-10 Technical Manual (09/06)

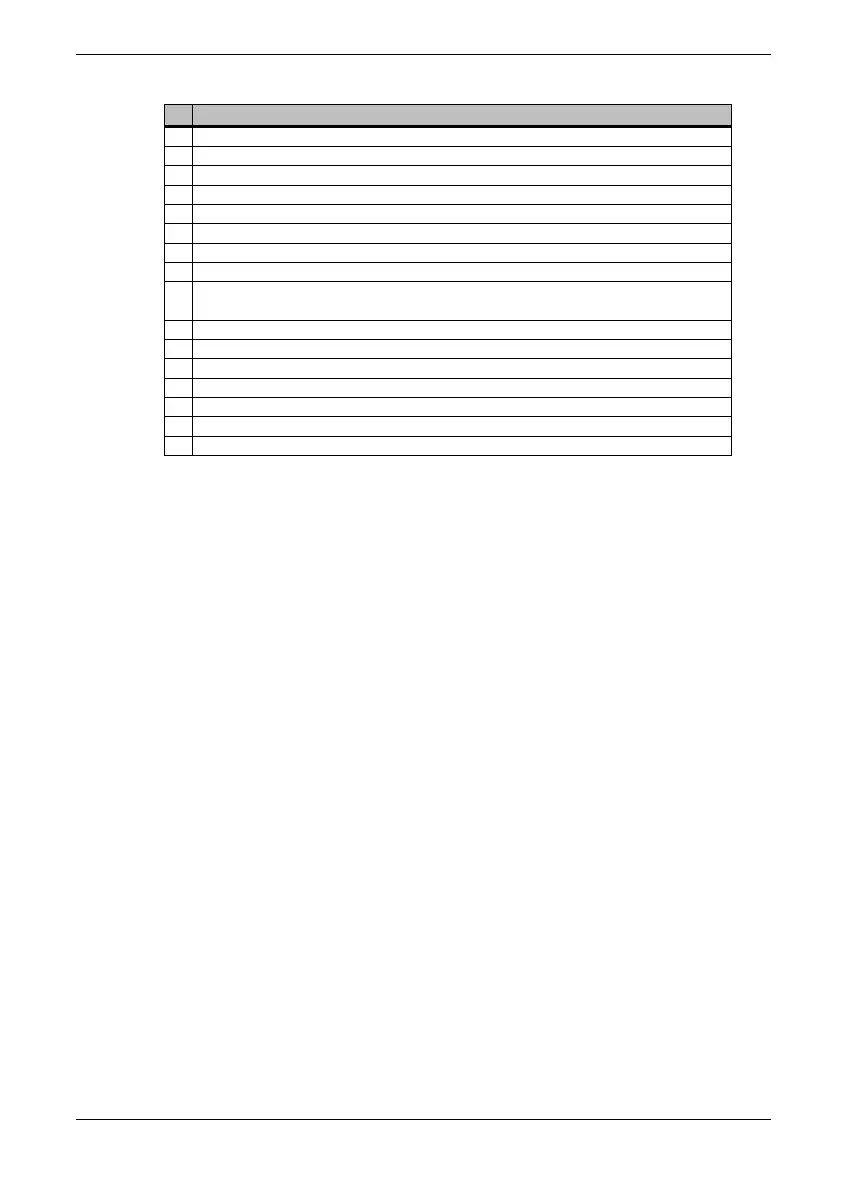

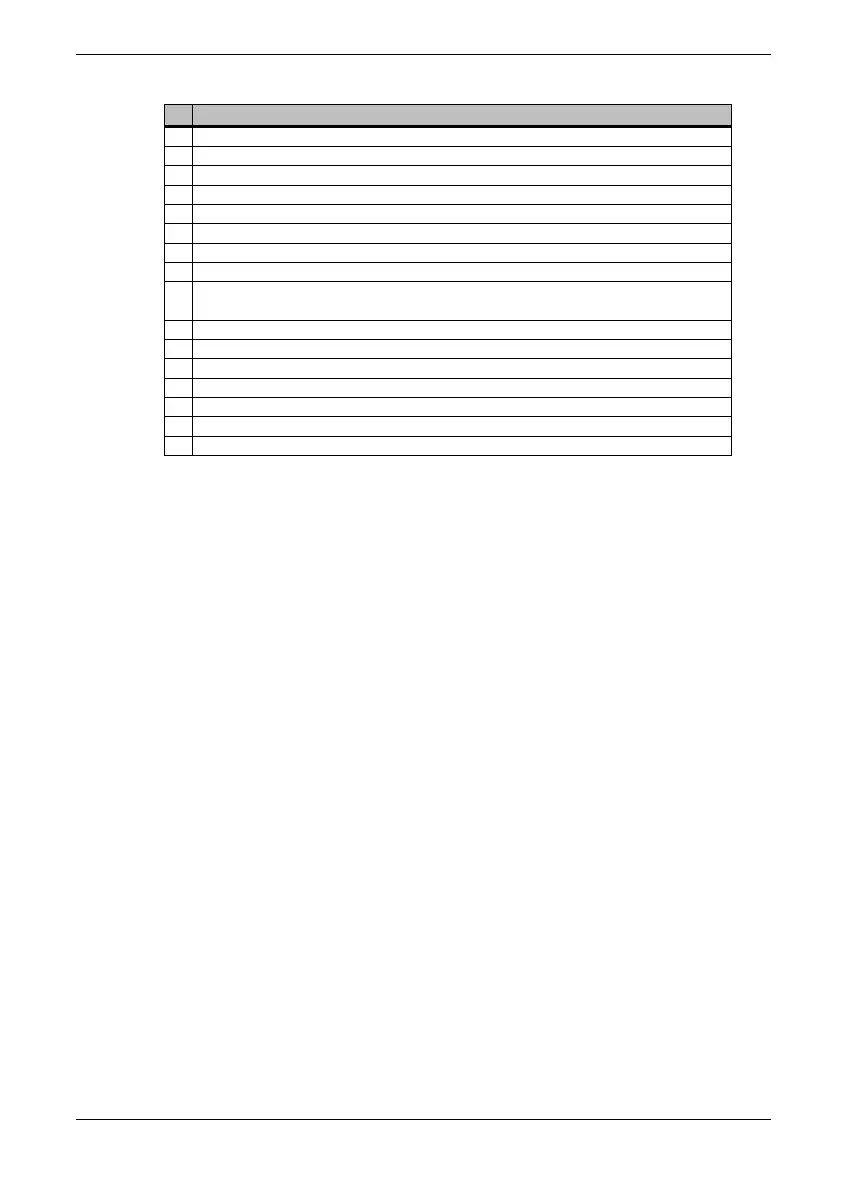

Table 7-4 Allocation of the status word bits (Speed control mode)

Bit Meaning

0 Ready for switch-on / not ready for switch-on

1 Ready for operation / not ready for operation

2 Operation enabled / operation inhibited

3 Fault / no fault

4 No OFF 2 / OFF 2

5 No OFF 3 / OFF 3

6 Switch-on inhibit / no switch-on inhibit

7 Warning / no warning

8

Set point/actual value within tolerance range /

Set point/actual value not within tolerance range

9 Control requested / operation on site

10 speed reached/ speed under range

11 Device-related

12 Device-related

13 Device-related

14 Device-related

15 Device-related

Each location in the PPO sent back to the PROFIBUS master is

specified according to

Table 7-3.

For example, it is decided to monitor 4 parameters, Speed feedback

(P9.01), Current feedback (P9.05), Motor volts (P9.07) and Motor

power (P9.08).

To configure the first parameter source, set P74.72 = 9.01

To configure the first parameter scale, set P74.73 = 1 (speed(%))

To configure the second parameter source, set P74.74 = 9.05

To configure the first parameter scale, set P74.75 = 7 (Current)

To configure the third parameter source, set P74.76 = 9.07

To configure the first parameter scale, set P74.77 = 10 (Volts)

To configure the final parameter source, set P74.78 = 9.08

To configure the first parameter scale, set P74.79 = 6 (Percent)

Note: When entering parameters via the Keypad, it is

important that any leading zeros are entered after the

decimal point. Entering 9.1 will result in P9.10 being

used, not P9.01.

Entering a value of 0 in a source pointer parameter will mean that a

corresponding value of 0 is written to the PROFIBUS network.

Loading...

Loading...