12 3 LEAK TESTING OVERVIEW

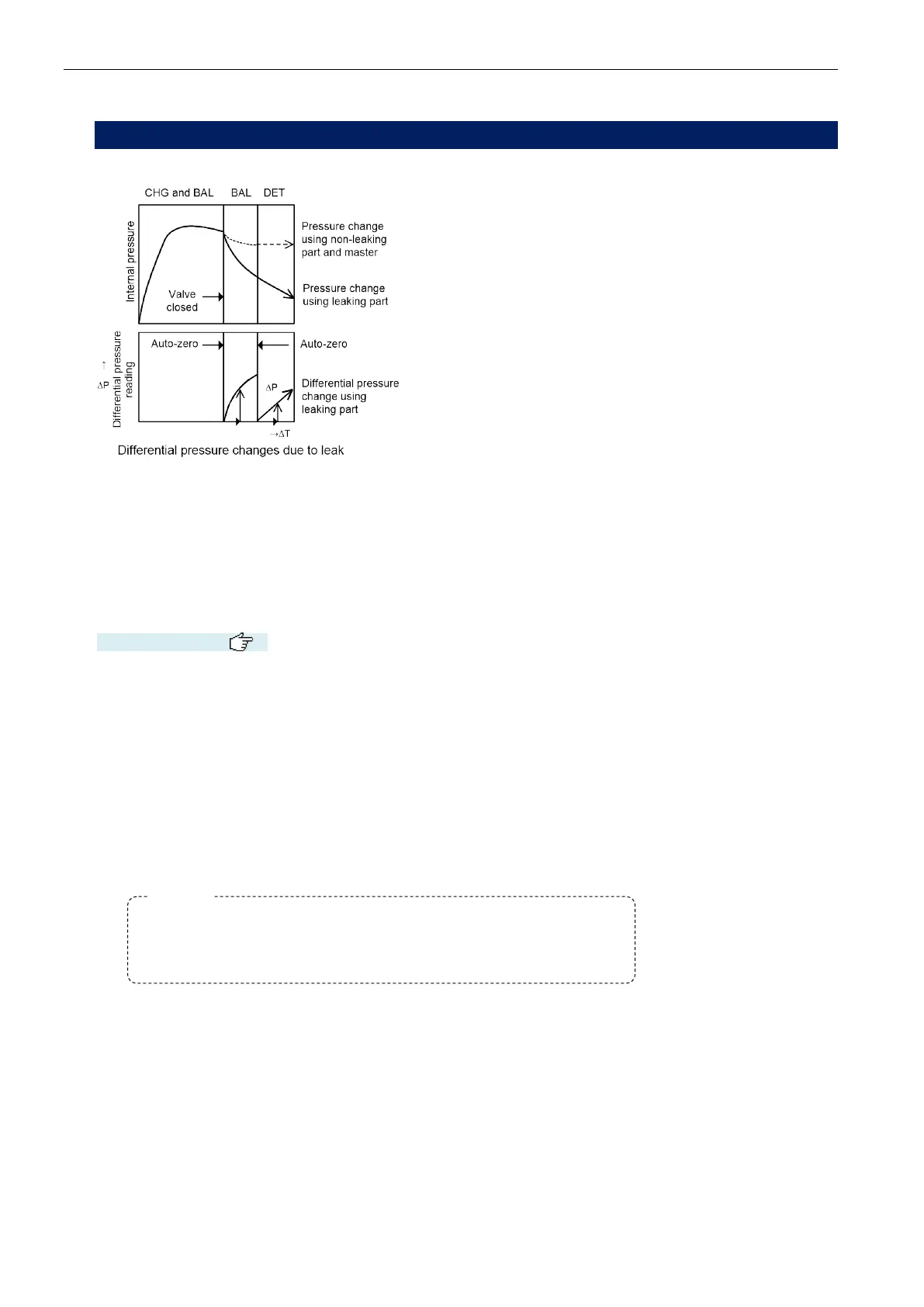

3.1.2 Internal pressure changes of the tested part and master

In the BAL and the DET stage, the differential pressure

resulting from leaks rises at a constant rate with time. In the

DET stage, the differential pressure sensor (DPS) output is

zeroed through an auto-zero operation before a differential

pressure reading is produced.

3

3

.

.

2

2

L

L

e

e

a

a

k

k

R

R

a

a

t

t

e

e

T

T

h

h

e

e

o

o

r

r

y

y

a

a

n

n

d

d

E

E

q

q

u

u

a

a

t

t

i

i

o

o

n

n

s

s

When a differential pressure is detected, it can be converted to leak rate unit mL/min by using a conversion

equation derived from Boyle's Law. Using the unit's leak calibration facility removes the need for

calculations based on the conversion equation.

(See Section 4.2. → )

a) Pressure and Volume Relationship

The relationship between pressure and volume is stated in Boyle’s law. Boyle’s law: for an ideal gas,

pressure multiplied by volume is a constant if the temperature is constant. In mathematical form:

PV = constant (where P is in absolute pressure units.)

A leak is measured by a change in pressure. The amount of leakage to atmosphere is calculated and

expressed by the following equation derived from Boyle’s law.

Leakage (ΔV

L

) = Ve × ΔP / Patm

Where:

Ve: Equivalent internal volume

∆P: Pressure drop due to a leak

Patm: Atmospheric pressure

The definition of internal equivalent volume (Ve) is the volume of air of

the entire Work-side pneumatic circuit at a particular test pressure. It

also includes a diaphragm deformation factor of the DPS. Ve is used

as leak coefficient K(Ve) in the leak rate calculation.

Loading...

Loading...