5 INSTALLATION 29

5

5

.

.

5

5

L

L

e

e

a

a

k

k

T

T

e

e

s

s

t

t

e

e

r

r

I

I

n

n

s

s

t

t

a

a

l

l

l

l

a

a

t

t

i

i

o

o

n

n

E

E

n

n

v

v

i

i

r

r

o

o

n

n

m

m

e

e

n

n

t

t

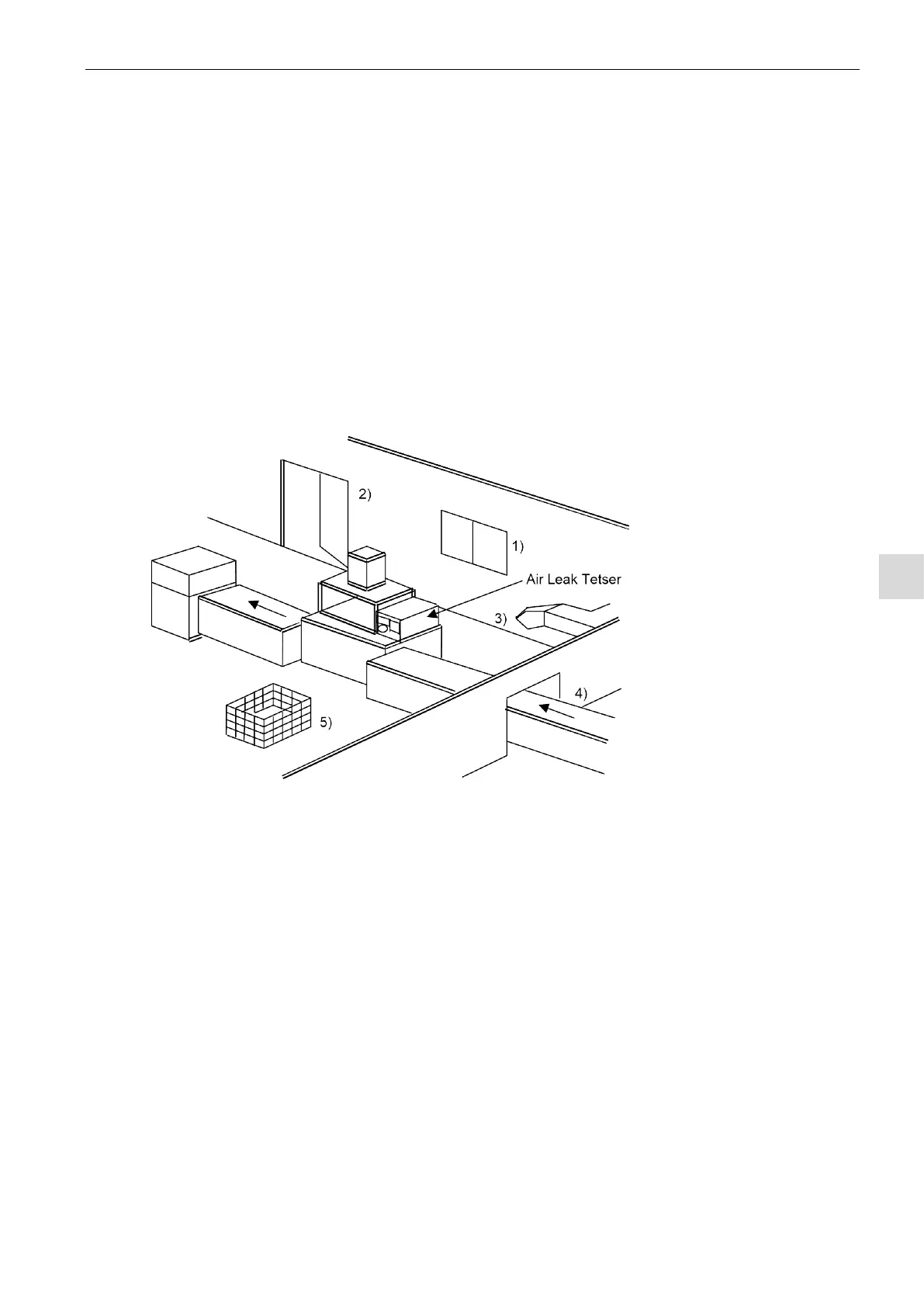

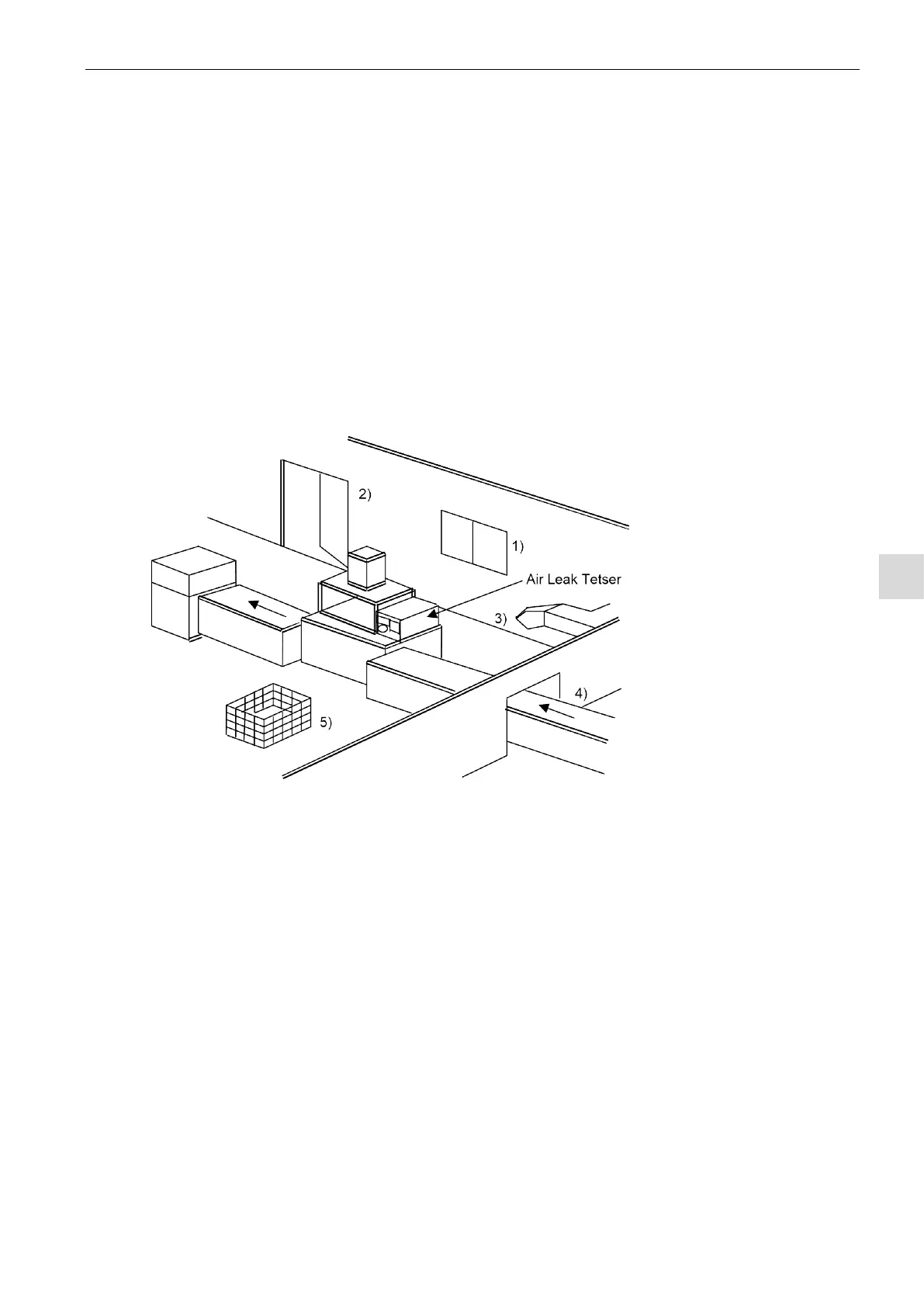

a) Location of Leak tester to Avoid Temperature Fluctuation

Avoid direct sunlight 1). Avoid direct wind due to doors opening and closing 2) or heating and cooling

vents 3).

When above cannot be avoided, use a curtain or screen. However, it is not good to cover the whole

test stand area completely because of temperature fluctuations that could occur in the tested part.

Therefore, partial covering will give better results.

b) Temperature changes in tested parts

Do not put the leak test station just after heating, cooling, welding or washing processes 4). The leak

tester works best with the tested part that is ambient temperature.

If the temperature of the floor and test bench are different, and the tested part is taken from the floor

and then test bench, heat transfer will take place between the tested part and the fixture 5). This will

cause an error. The tested part should be stored at the same level as the test bench in order to keep

the temperature the same.

Loading...

Loading...