26 5 INSTALLATION

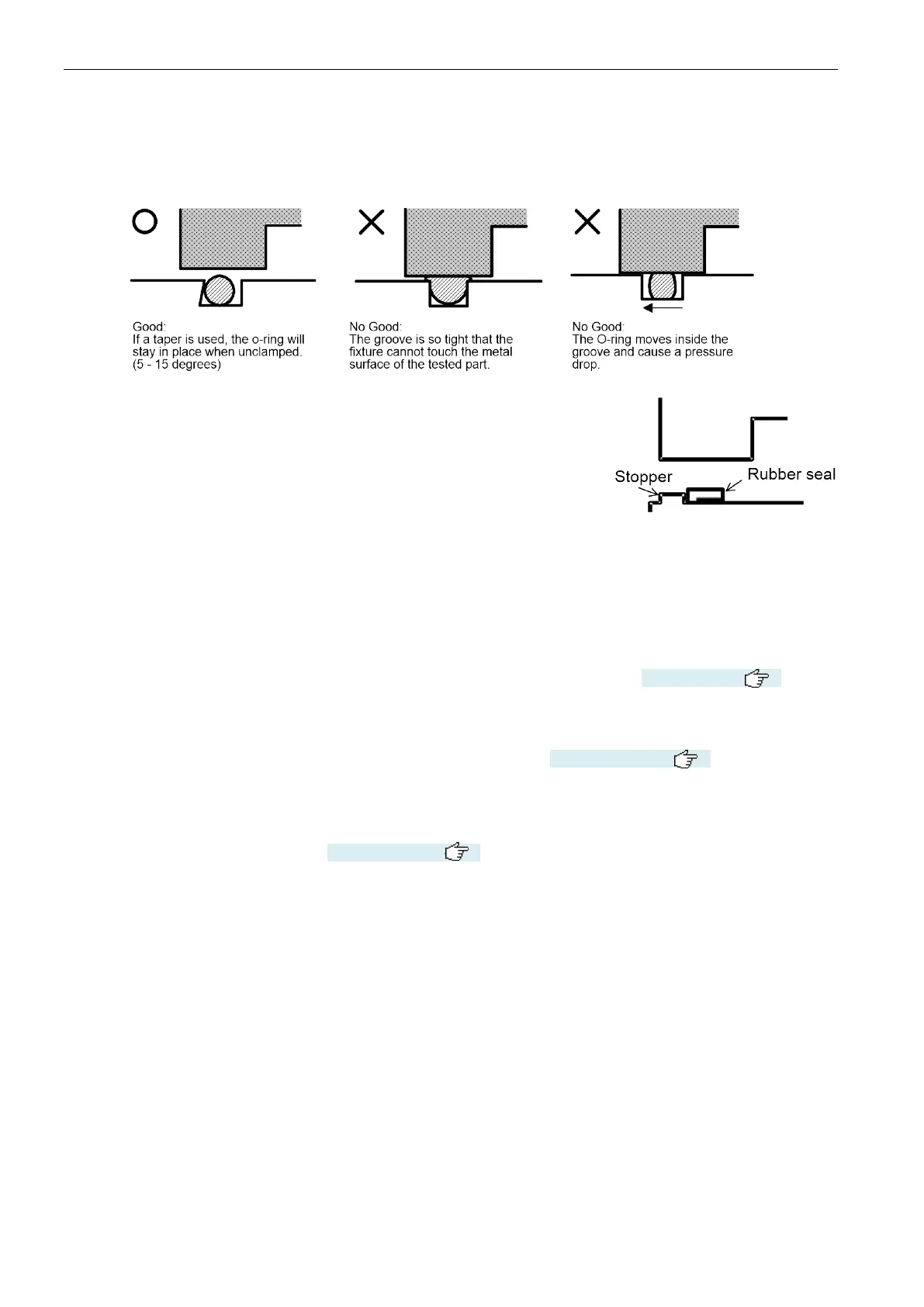

5) Use of O-ring

If there is an air space that isn’t pressurized at the side of the O-ring, the O-ring will move and causes a

pressure drop. If O-ring groove is so tight, the fixture cannot touch the metal surface of the tested part,

which results in damage to the O-ring or erratic reading due to spongy fixturing.

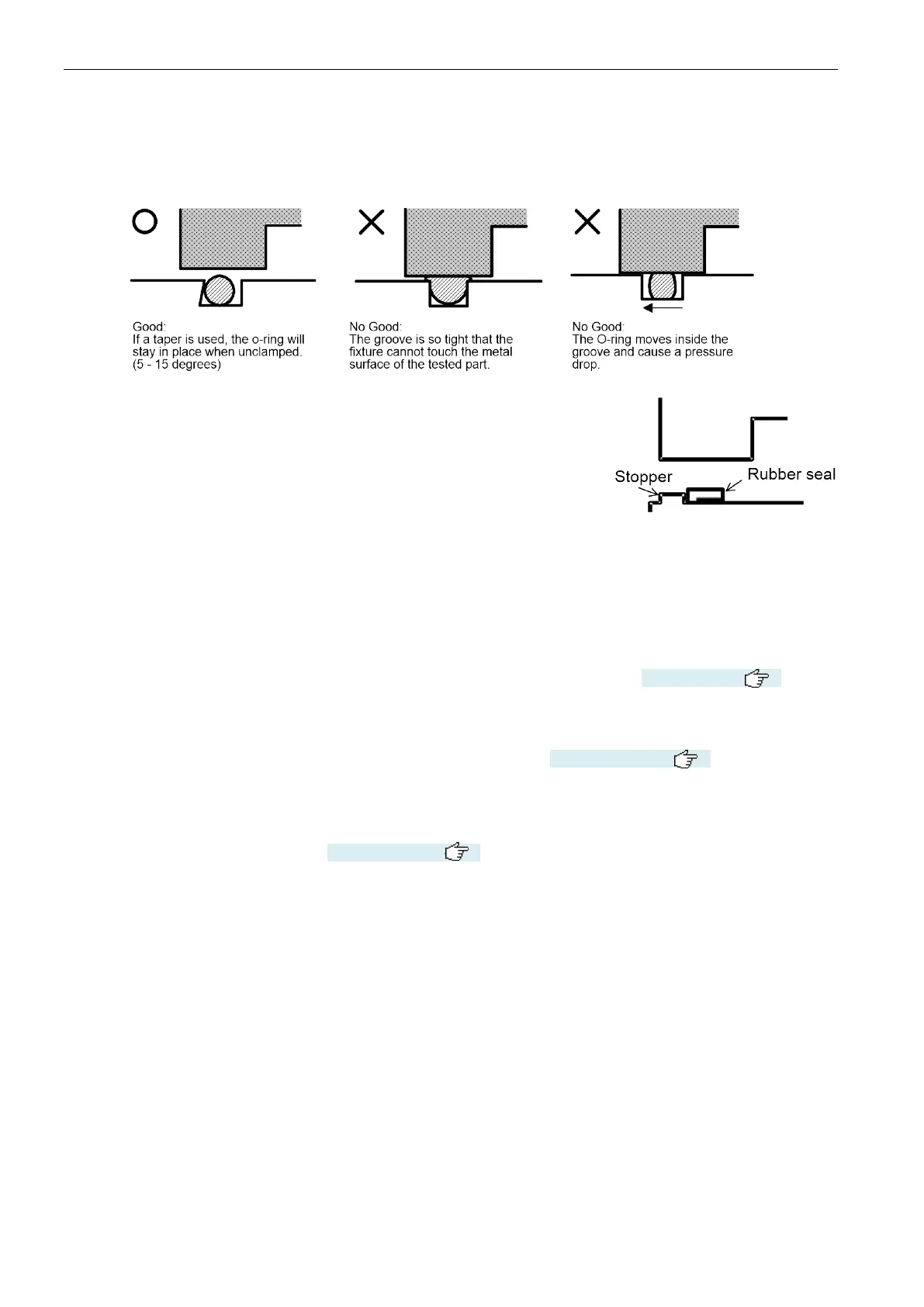

6) Use of flat rubber seal

Use a positive stop to prevent deformation of seal packing when

using air or oil cylinders as a clamping mechanism. A metal

stopper helps seal packing to stabilize perfectly because normally

the clamping pressure added to the seal packing causes the

packing to move intermittently.

7) Combining with water dunk test

Temperature effects

Temperature changes of tested part and/or fixture after submerging them under water may temporarily

affect tester reading.

Tester malfunction due to water contamination

Tester may get contaminated by water causing tester malfunction at exhaust process of water dunk test.

To avoid the trouble, use the following precautions:

• While the part is submerged, the tester should always be on charge hold. Never exhaust air while

the tested part is submerged under water.

• Put an external exhaust valve between the tester and the tested part (Refer to 4.5.2 → )

• I

nstall leak tester higher level than water surface.

8) Using multiple leak testers on a single system

To ensure that the all the clamping fixtures do not interfere each other, build each one of them

independently. Also be sure to put regulator independently. ((See Section 4.7 → )

9) Testing multiple independent measurement points (Exhaust interference control)

If one leak tester exhausts while a measurement is in progress, variations in the clamp seal could

influence the measurement accuracy of the other leak testers. Mutual exhaust interference can be

prevented by performing exhaust on all leak testers concurrently. This leak tester allows external

control of the exhaust timing (see Section 4.8 → ).

10) T

ested parts that are liable to deformation

Have a restraint installed to eliminate deformation.

11) Fixture pressure supply port

Provide a port where dust, oil, and water will not be accumulated.

If the sealing surface of the tested part is varied in angle, have a floating mechanism mounted on the

clamp shaft.

Loading...

Loading...