29

0306 / 13 013 497A

Installation

Assembly

Assembly

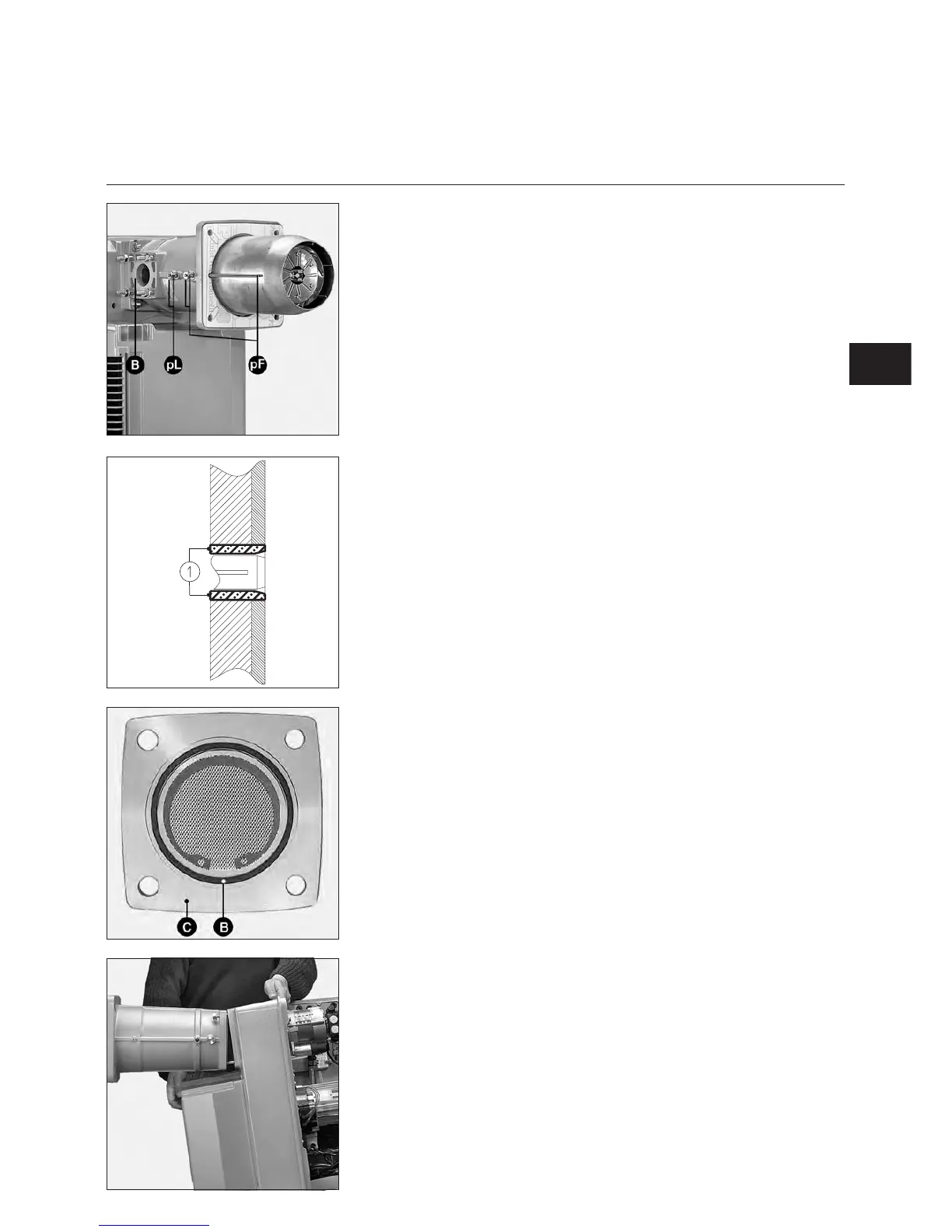

Boiler face

•

Prepare face according to the

enclosed space requirement

diagram.If required, insert a counter

face plate (option).

Pierce: Ø 195 (or Ø 172 with an

opening on the same side as the

gas supply for the tube of the

furnace pressure connector).

•

Fill in space 1 with recommended

heat-resistant material or material

supplied by the boiler manufacturer.

m

Do not obstruct combustion

chamber pressure take-off pF.

Combustion head

•

Remove the combustion

components, store them on standby

in an area sheltered from impacts.

•

Position the combustion head in

order to produce a horizontal

connection with the gas train, on the

right or on the left. No other

assembly positions are

authorised.

• Mount and fix combustion head with

its seal on front of burner.

• Check subsequently for leaks.

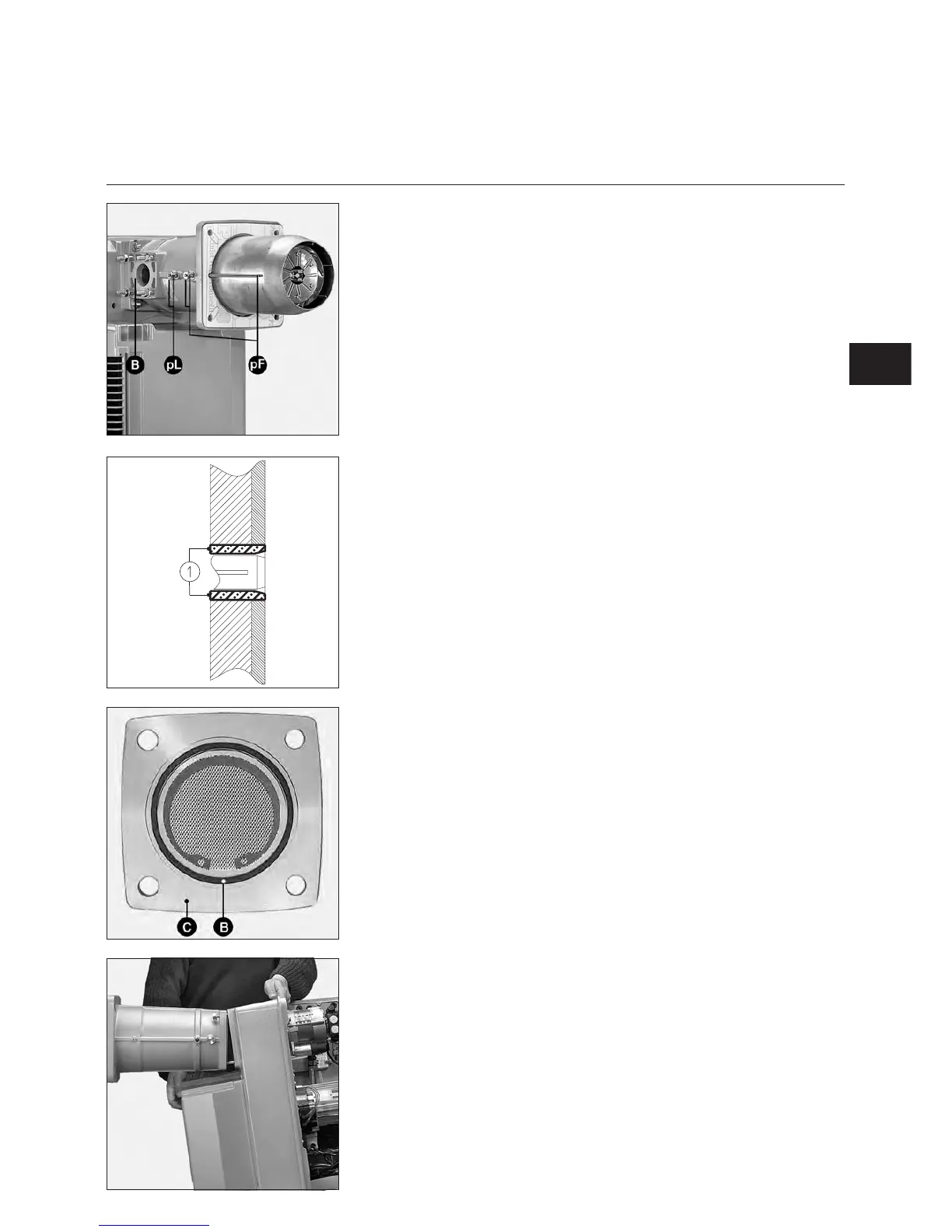

Gas manifold

• Check presence and position of

O-ring B in manifold C flange.

• When fitting gas manifold, valve

coils must be in the vertical top

position.

Important

When using a left-mounted VGD gas

train, it is necessary to pivot the SKP70

regulator 180°.

To do this:

•

Remove the SKP70 regulator.

•

Remove the connector (3P+T) on

the side of the regulator and

remount it opposite.

m

Seal off the old position of the

connector.

•

Refit the regulator once it has been

pivoted a half turn (180°).

Burner body

Installation can occur with the volute

low down or high up following the

instructions described in the paragraph

“combustion components start-up”.

No other assembly positions are

authorised.

Volute low down :

•

Remove the two lower nuts and

unscrew as far as possible the two

upper nuts from the body of the

burner.

•

Lean the body of the burner forward,

and insert the upper studs into the

slots in the spacer.

•

Rest the burner body on the spacer

and tighten the four nuts.

Volute high up : reverse previous

instructions.

EN

•

Place the linking tubes of the

combustion components (stored on

stand-by) on the pump without pulling

them too tight or gripping them too

hard.

Loading...

Loading...