31

0306 / 13 013 497A

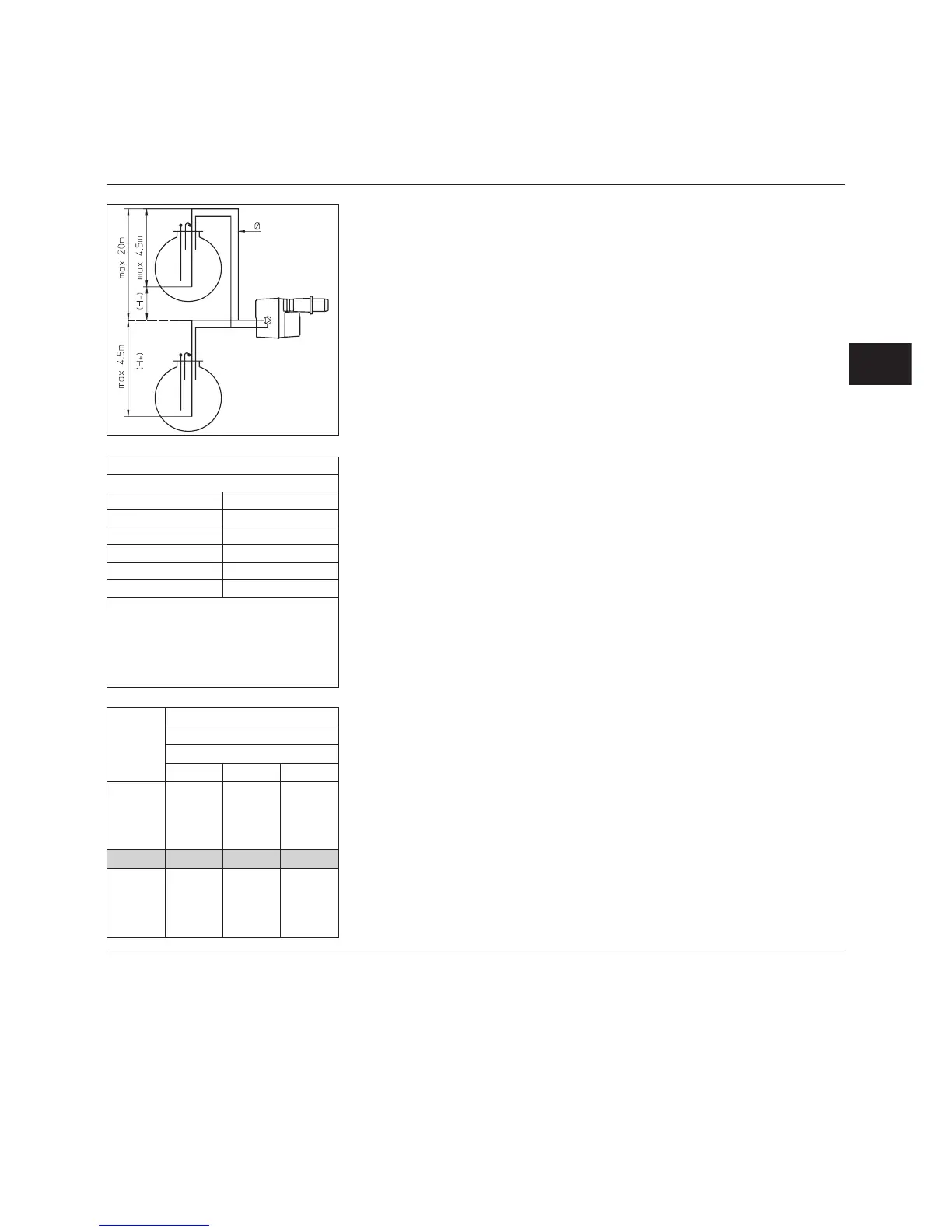

Altitude correction

Suction (H+) or loading (H-) pump

Altitude (m) Dummy H (m)

0-500 0

501-800 0,5

801-1300 1,0

1301-1800 1,5

1801-2200 2,0

e.g. Altitude 1,100m Dummy H=1m Real H=2m

Suction corrected H 2 + 1 = 3m

Load corrected H 2 - 1 = 1m

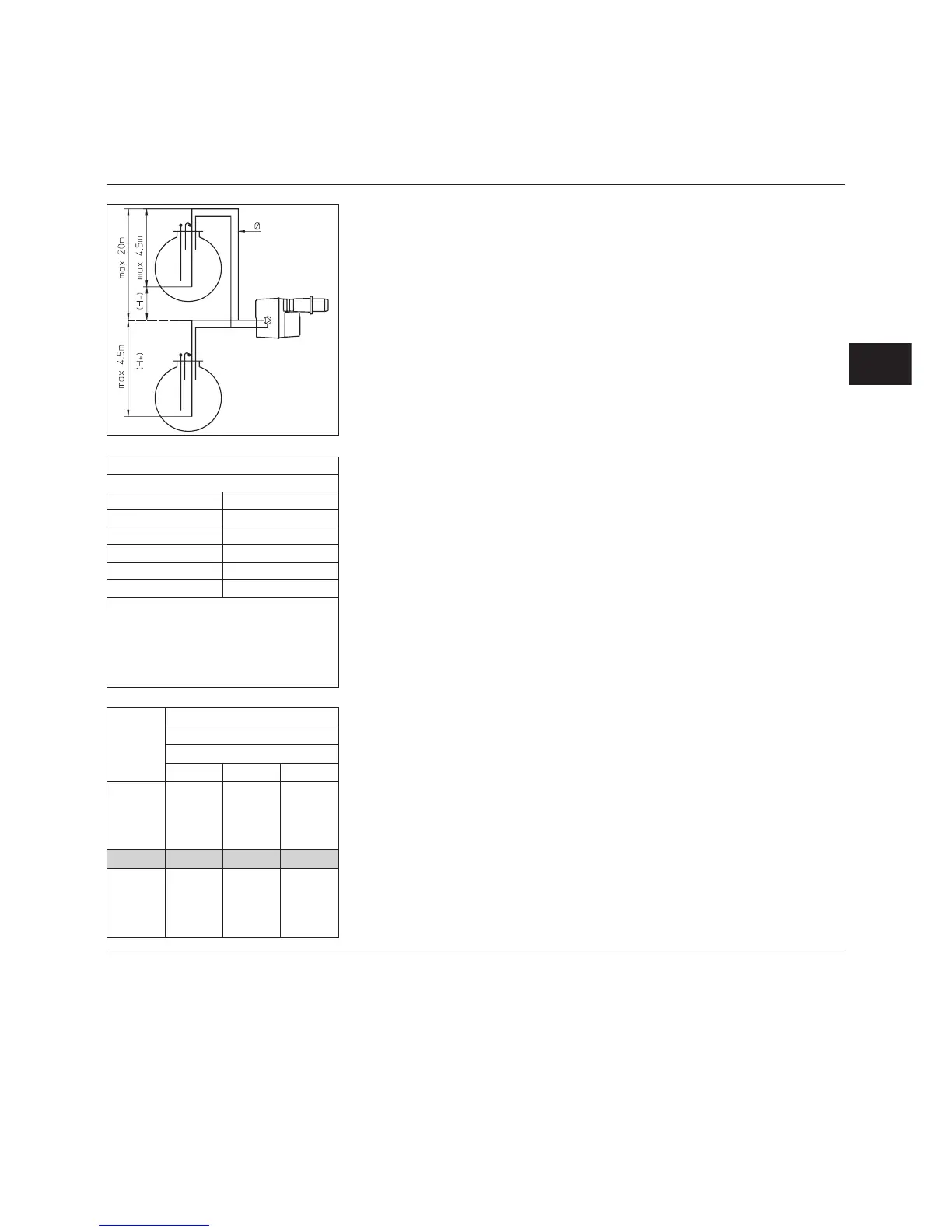

Choose pipe diameter in table, according to length

between tank and pump.

If suction corrected H exceeds 4m, have transfer pump

available (max. pressure 2 bars).

Corrected

H

(m)

Double tube installation L (m)

C 75 / C 100

Ø (mm)

10/12 12/14 14/16

4,0

3,0

2,0

1,0

+0,5

51

45

38

32

29

83

83

82

69

62

83

83

83

83

83

0 265683

-0,5

-1,0

-2,0

-3,0

-4,0

22

19

13

6

0

49

42

29

16

2

83

80

55

31

6

Fuel oil connection

Enclosed diagrams provide required

pipe diameters.

There are two following possibilities:

–

Direct suction:

According to length L and suction or

load height H and chance mishaps;

These lengths include the presence

of a quarter-turn hand-operated

valve, a check valve and four

elbows.

Maximum negative pressure of

0.4bar.

–

Transfer loop:

According to the type of facility,

booster pump characteristics will

have to meet several criteria,

notably:

–

hourly flow,

–

fluid flow speed,

–

maximum boosting pressure.

Preference should be given to this

type of installation, in order to

obtain long spray pump life.

m

Important

In both cases, it is compulsory to

fit a 120µm² filter and quarter-turn

hand-operated valve on the suction

or booster (not supplied).

Important:

Suction:

•

Totally fill suction pipe between

spray pump and tank down-pipe

with fuel oil.

Transfer loop:

•

Fill, boost, drain and set pressure in

circuit at 2bar max. It is advisable

to install a pressure switch to limit

burner operation to boost pressure.

•

Check for possible leaks.

Installation

Fuel oil connection

EN

Loading...

Loading...