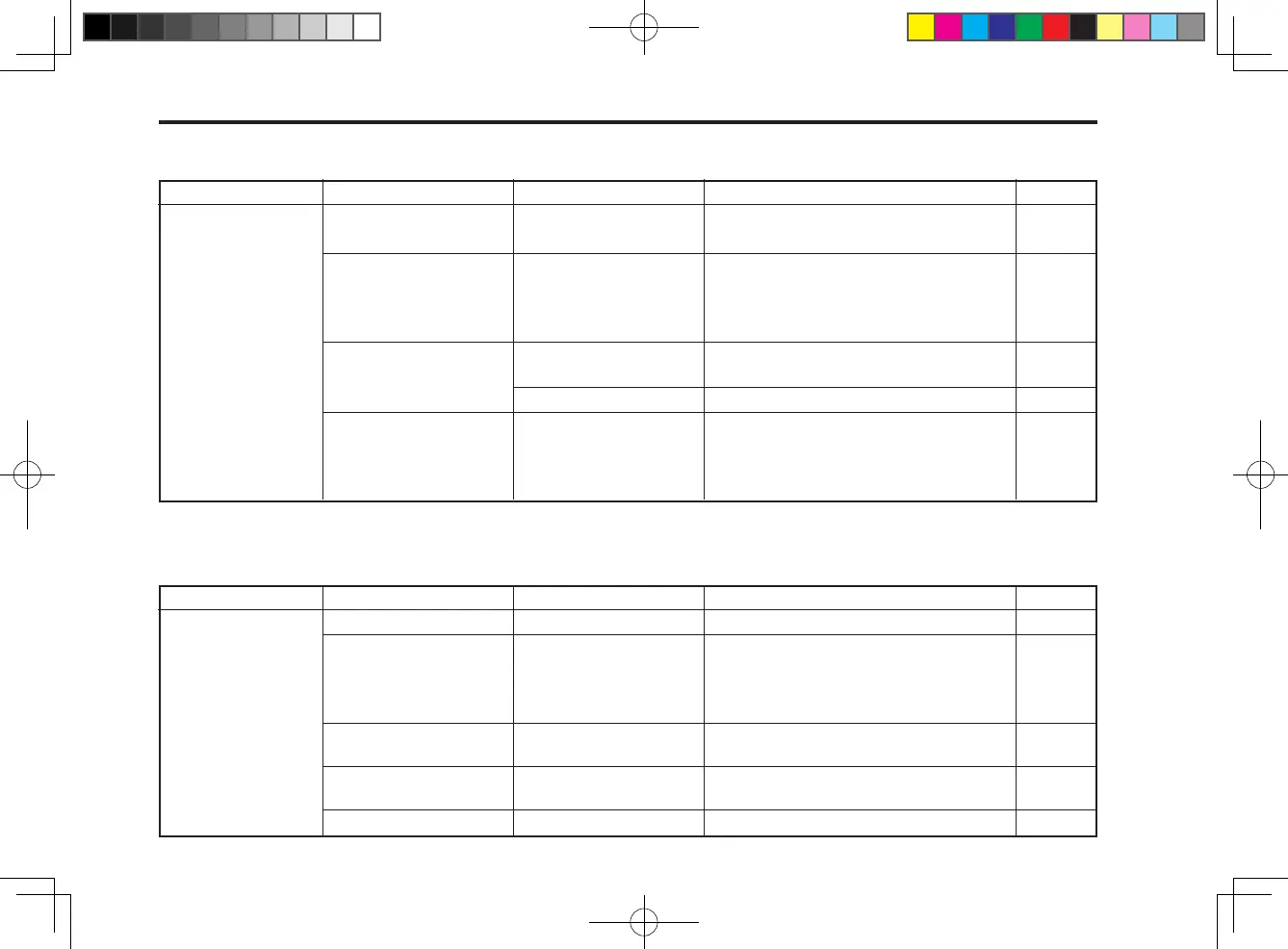

ReferenceTroubleshooting

Adjust the tension

Adjust position of ear to be located at the

FEEDING-DEPTH INDICATING LABEL on

the thresher inlet by the feeding depth con-

trol switch

Shift the elevator and the auxiliary levers

Adjusting the slide rails on the elevator frame

Normally engage the lever to STANDARD

However, when reaping slowly (0.1~ 0.3 m/s)

near a field bank or crop roots are pulled

out, shift the lever to SLOW

Checking point

Chain tension

Conveyor-belt

Feeding depth control

lever (automatic)

Manual feeding depth

control switch (manual)

Elevator shift lever

Auxiliary shift lever

Slide rail

Auxiliary shift lever

THE FEEDING CONVEYOR FAILS TO CONVEY CROPS OR CROPS ARE UNEVENLY CONVEYED

Immediate actions

Stop reaping and

disengage the reap-

ing clutch lever

Stop the engine

Cause

The chain or conveyor belt is

loose

The feeding depth control is

not proper

Crop are unevenly elevated

by the elevator unit

At a low speed, crops are

unevenly conveyed

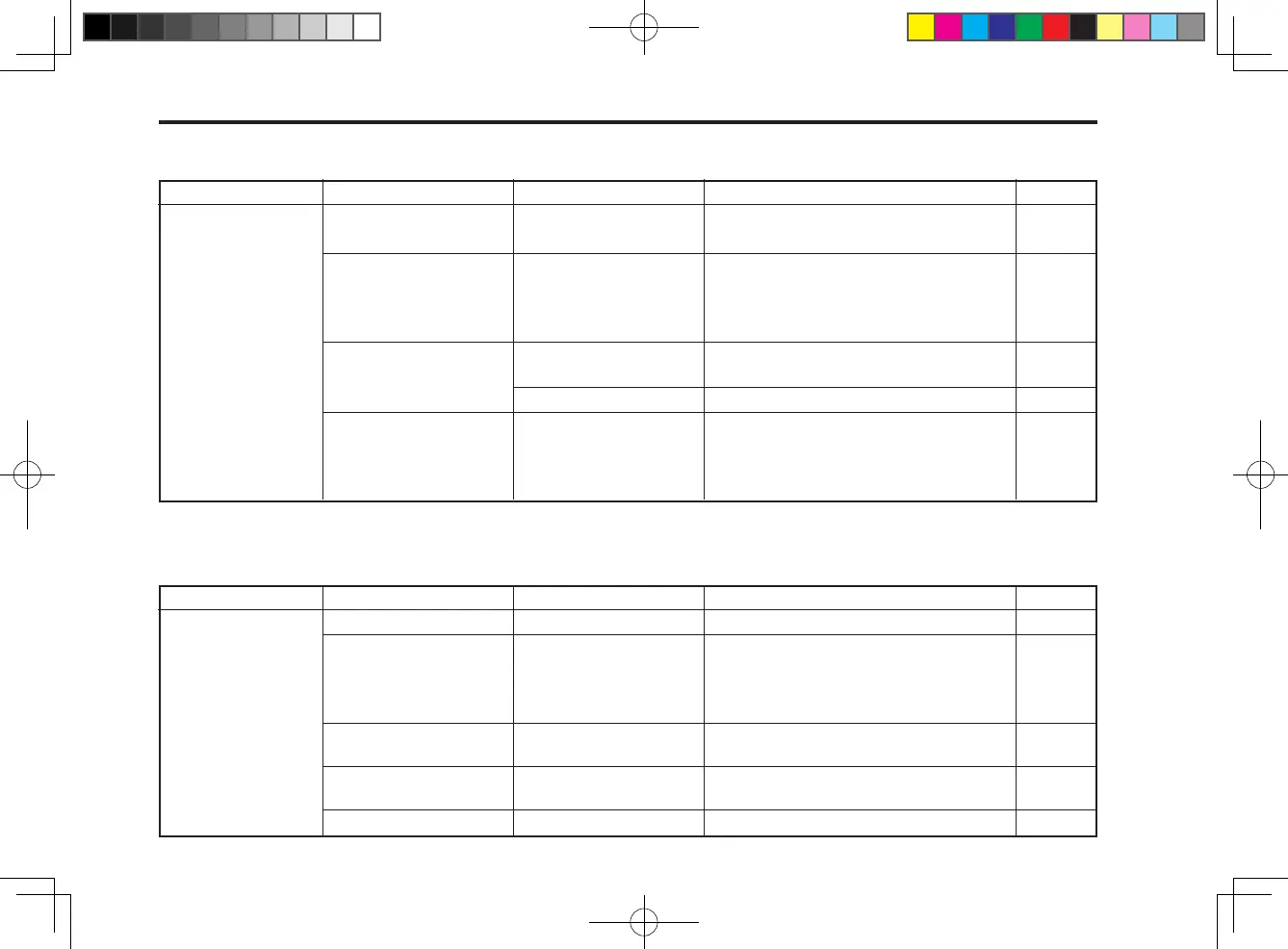

ReferenceTroubleshooting

Replace it with new one

Adjust position of the ear end to be located

at th e F EED I N GD E P TH - I NDI C ATIN G

LABEL in the thresher inlet by the feeding

depth control switch

Adjust clearance

Remove the straw

Replace the cutting blade

Checking point

Cutting blade

Feeding depth control

unit (automatic)

Manual feeding depth

switch (manual)

C l e a r a n c e b e t w e e n

blades

The gap between cutting

blades

Cutting blades

LENGTH OF STRAWS CUT BY THE STRAW CUTTER BAR BECOMES LONG

Immediate actions

St o p th e r e a p i n g

and the engine

Cause

The cutting blade is broken

The f e e d i n g depth is too

deep

Clearance between blades is

too wide

Straw is stuffed between the

cutting blades

Cutting blade is worn out

Loading...

Loading...