Maintenance Section

-148-

6. Remove the dip stick/filter cap. Fill the drive axle

housing with oil. See “Lubricant Specification - Drive

Axle Oil” and “Refill Capacity”.

7. Start the lift truck. With the engine at low idle, place

the directional control lever to the NEUTRAL.

8. Maintain the oil level between lower mark and upper

mark on the dip stick/filter cap.

9. Install the dip stick/filter cap.

Engine Oil & Filter - Change

TIER II Diesel Engine (DB58S) Only

See topic, “Engine Oil & Filter(Diesel Engine Only) -

Change” in “First 50-100 Service HOURS”.

Inching & Brake Control shaft -

Lubricate

Lubricate two fittings for the inching and brake pedal

control shaft.

Horn & Lights (If Equipped) – Check

1. Press horn button, to determine if horn is

operational.

2. Check and replace all defective gauges.

3. Check all lights such as warning, directional, backup,

driving and flood lights for correct operation.

Replace all burned out bulbs. Have repairs made if

needed.

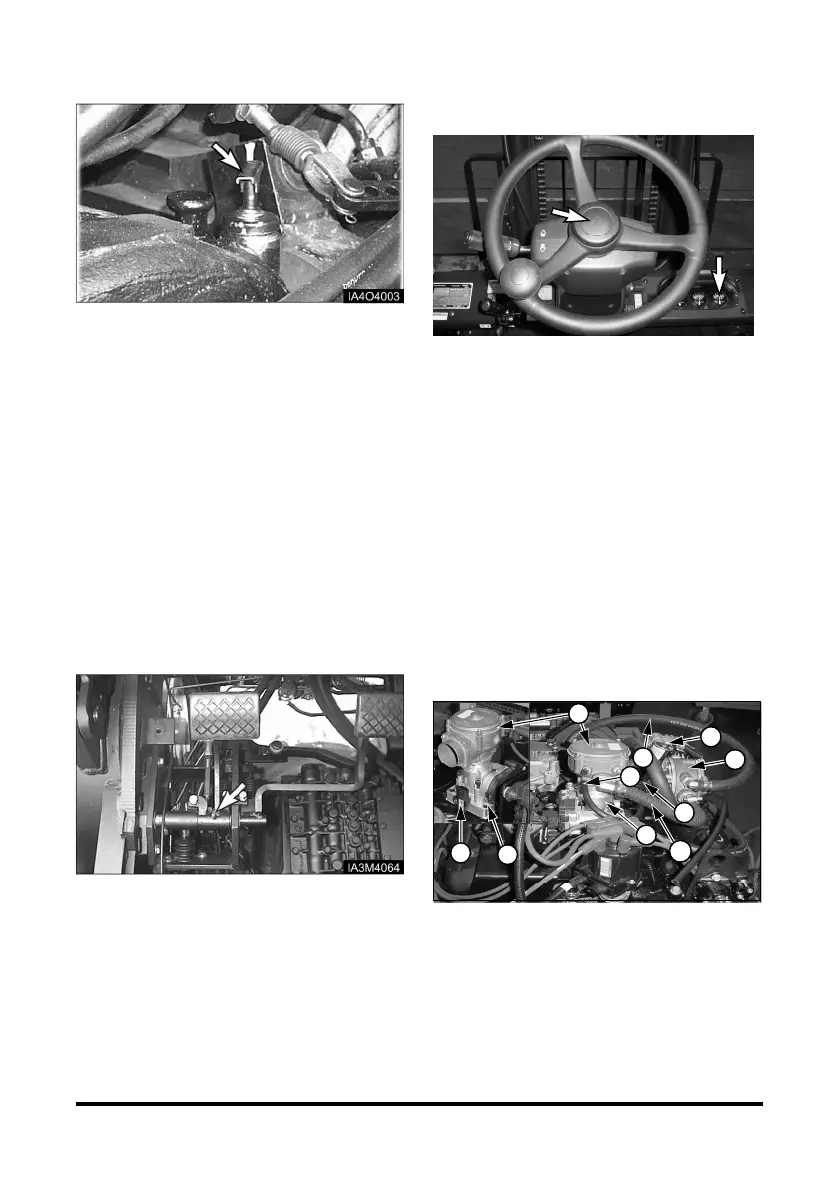

Inspect Vacuum Lines and Fittings

(G643E Engine only)

1. Visually inspect vacuum lines and fittings for

physical damage such as brittleness, cracks and

kinks. Repair/replace as required.

2. Solvent or oil damage may cause vacuum lines to

become soft resulting in a collapsed line while the

engine is running.

3. If abnormally soft lines are detected, replace as

necessary.

(1) LP fuel lock-off, (2) LP regulator/converter

(3) Fuel Trim Valve(FTV), (4) Adapter-Throttle body

(5) TMAP sensor, (6) Adapter-Manifold, (7) LP mixer

(8) Vacuum lines, (9) Coolant lines, (10) LP fuel line

5

6

4

3

2

1

7

8

9

1

Loading...

Loading...