Maintenance Section

-149-

Fuel Trim Valve(FTV) Inspection

(G643E Engine only)

1. Visually inspect the Fuel trim valve(3) for abrasions

or cracking. Replace as necessary.

2. To ensure the valve is not leaking a blow-by test

can be performed.

3. With the engine off, disconnect the electrical

connector to the FTV.

4. Disconnect the vacuum line from the FTV to the

pressure regulator/converter, at the converter’s tee

connection.

5. Lightly blow through the vacuum line connected to

the FTV. Air should not pass through the FTV when

de-energized. If air leaks past the FTV when de-

energized, replace the FTV.

Inspect Electrical System (G643E

Engine only)

1. Check for loose, dirty or damaged connectors and

wires on the harness including: Fuel lock-off, TMAP

sensor, O2 sensor, Electronic throttle, Control

Relays, Fuel Trim Valve, Foot Pedal, and Distributor

sensor.

2. Repair and/or replace as necessary.

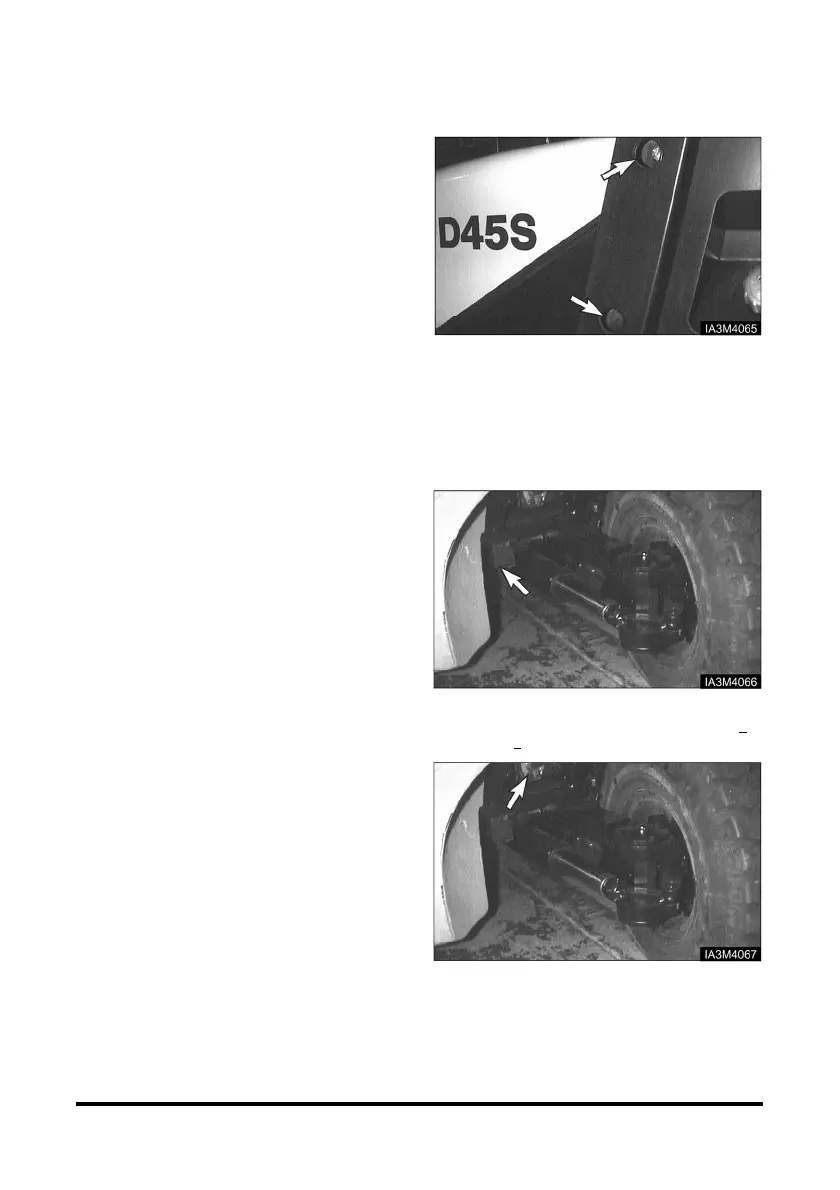

Overhead Guard – Inspect

1. Check tightness of overhead guard mounting bolts

at 80 N•m (60 lb•ft).

2. Check overhead guard for bent or cracked sections.

Have repairs made if needed.

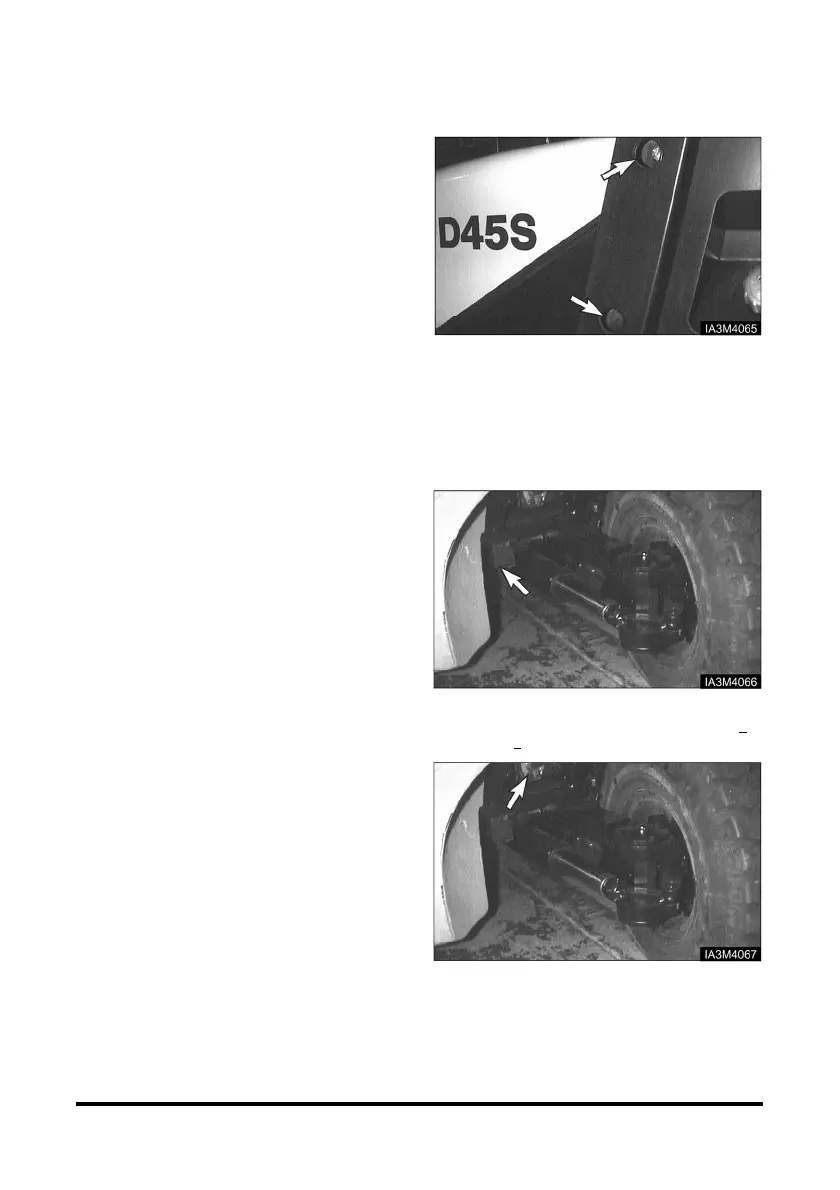

Steer Suspension - Inspect

1. Inspect the suspension mounting bolts. Tighten

suspension mounting bolts, if necessary, to 240+

30

N•m (180+

20 lb•ft).

2. Look for leaks at the power steering hose

connections.

3. Remove any trash buildup on the suspension or the

steer axle.

Loading...

Loading...