1 Troubleshooting

Service manual

7

ATXP20~35L2V1B + FTXP20~71L2V1B + ARXP20~35L2V1B +

RXP20~71L2V1B

Split Comfora R32

ESIE18-01 – 2019.02

6 Perform a check of the 4‑way valve. See "2.1 4-way valve"on

page18.

Possible cause: Faulty 4‑way valve.

7 Perform a check of the expansion valve. See "2.3 Expansion

valve"on page23.

Possible cause: Faulty expansion valve.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

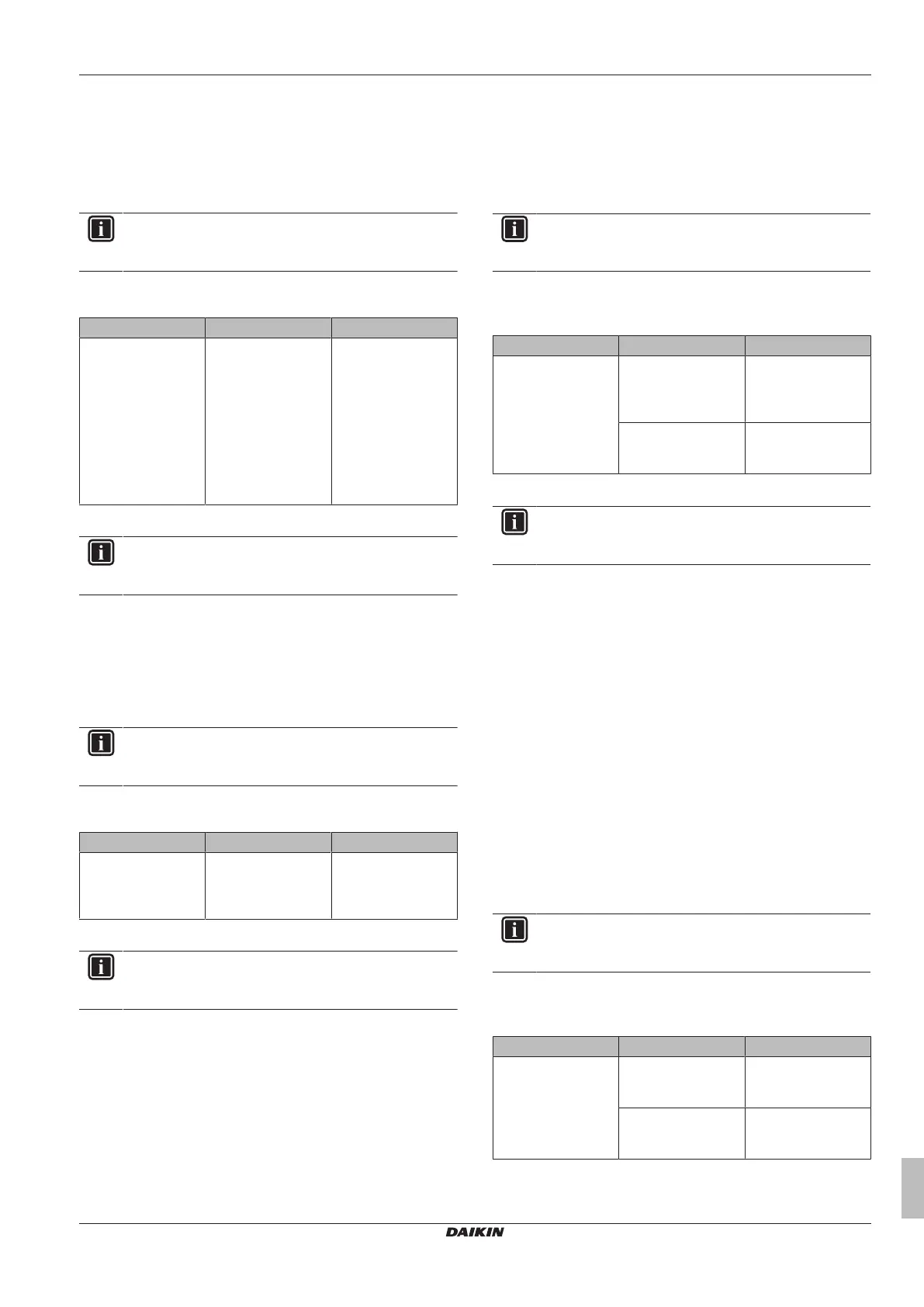

1.5.10 E7-00 – Fan lock abnormality

Trigger Effect Reset

Fan does NOT start

15~30seconds after

ON signal.

It can occur that the

error code is

triggered when the

fan motor is running

caused by a faulty

rotating sensor

signal.

Unit will stop

operating.

Manual reset via user

interface.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the outdoor unit fan motor. See

"2.9Outdoor unit fan motor"on page34.

Possible cause: Faulty outdoor unit fan motor.

2 Perform a check of the inverter PCB. See "2.7Inverter PCB"on

page31.

Possible cause: Faulty power module = inverter PCB.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

1.5.11 E8-00 – Input overvoltage abnormality

Trigger Effect Reset

Compressor running

current exceeds

standard value for

2.5seconds.

Unit will stop

operating.

Manual reset via user

interface.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Check the outdoor temperature. See "3.3 External factors" on

page47.

Possible cause: Outdoor temperature is out of operation

range.

2 Perform a check of the compressor. See "2.2Compressor"on

page20.

Possible cause: Faulty compressor.

3 Perform a check of the inverter PCB. See "2.7Inverter PCB"on

page31.

Possible cause: Faulty power module = inverter PCB.

4 Check if the power supply is conform with the regulations. See

"3.1Power supply"on page44.

Possible cause:

▪ Faulty or disturbance of the power supply (imbalance

>10%),

▪ Power drop,

▪ Short circuit.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

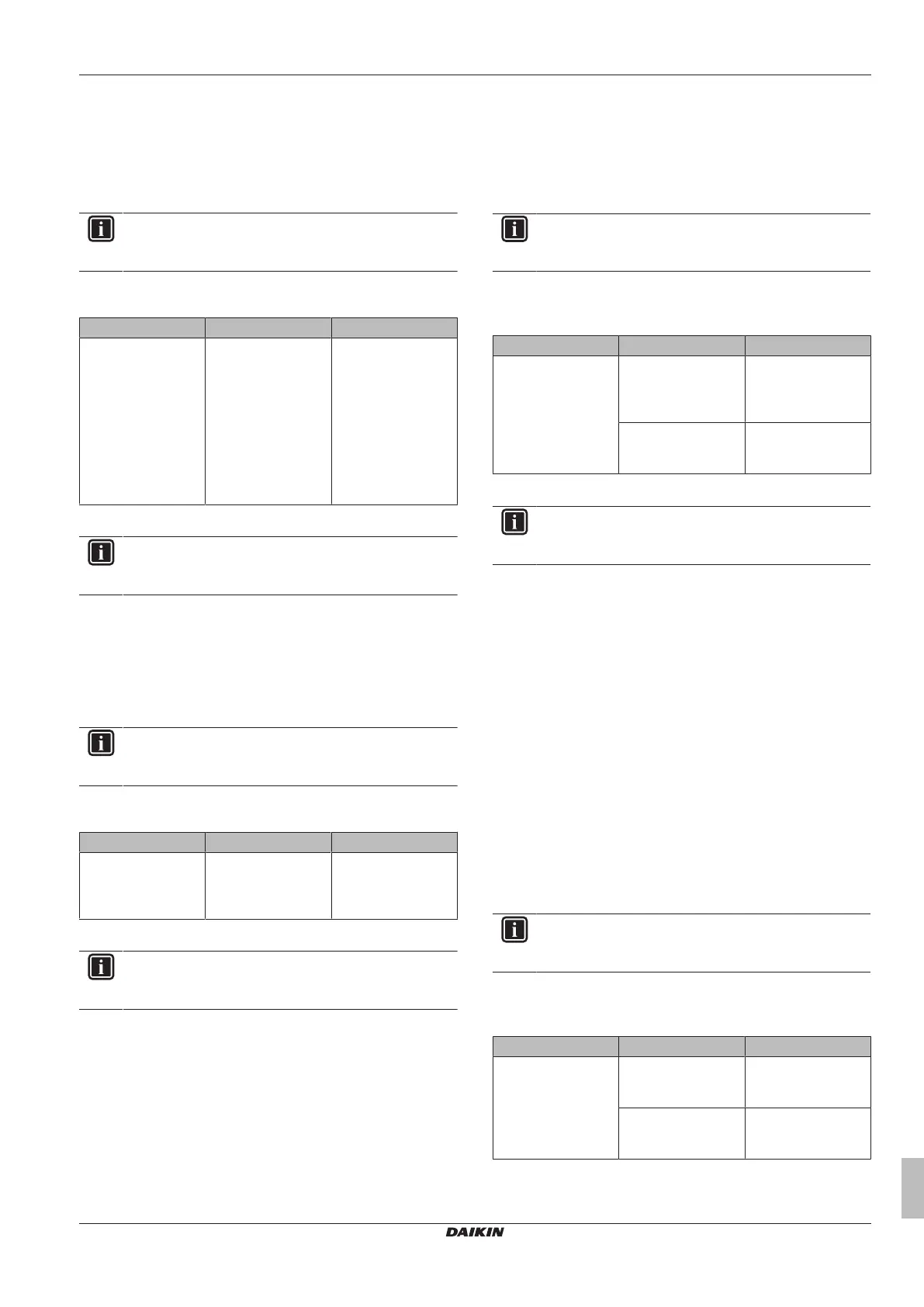

1.5.12 EA-00 – Cooling/Heating switch

abnormality

Trigger Effect Reset

Room thermistor is

NOT functioning

within operation

range.

Unit will NOT stop

operating.

Automatic reset after

a continuous

operation of

10minutes.

If the error occurs too

soon: unit will stop

operating.

Manual reset via user

interface.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the 4‑way valve. See "2.1 4-way valve"on

page18.

Possible cause: Faulty 4‑way valve.

2 Perform a check of the main PCB. See "2.8 Main PCB" on

page32.

Possible cause: Faulty main PCB.

3 Perform a check of the room thermistor. See

"2.13Thermistors"on page41.

Possible cause: Faulty room thermistor.

4 Perform a check of the refrigerant circuit. See "3.2 Refrigerant

circuit"on page45.

Possible cause:

▪ Stop valve is closed,

▪ Clogged refrigerant circuit,

▪ Refrigerant circuit NOT charged correctly,

▪ Humidity in the refrigerant circuit,

▪ Non-condensables in the refrigerant circuit,

▪ Leaking refrigerant circuit.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

1.5.13 F3-00 – Discharge pipe temperature stop

abnormality

Trigger Effect Reset

Discharge pipe

thermistor detects a

too high temperature.

Unit will NOT stop

operating.

Automatic reset when

temperature drops

normal level.

If the error re-occurs

too soon: unit will

stop operating.

Manual reset via user

interface.

Loading...

Loading...