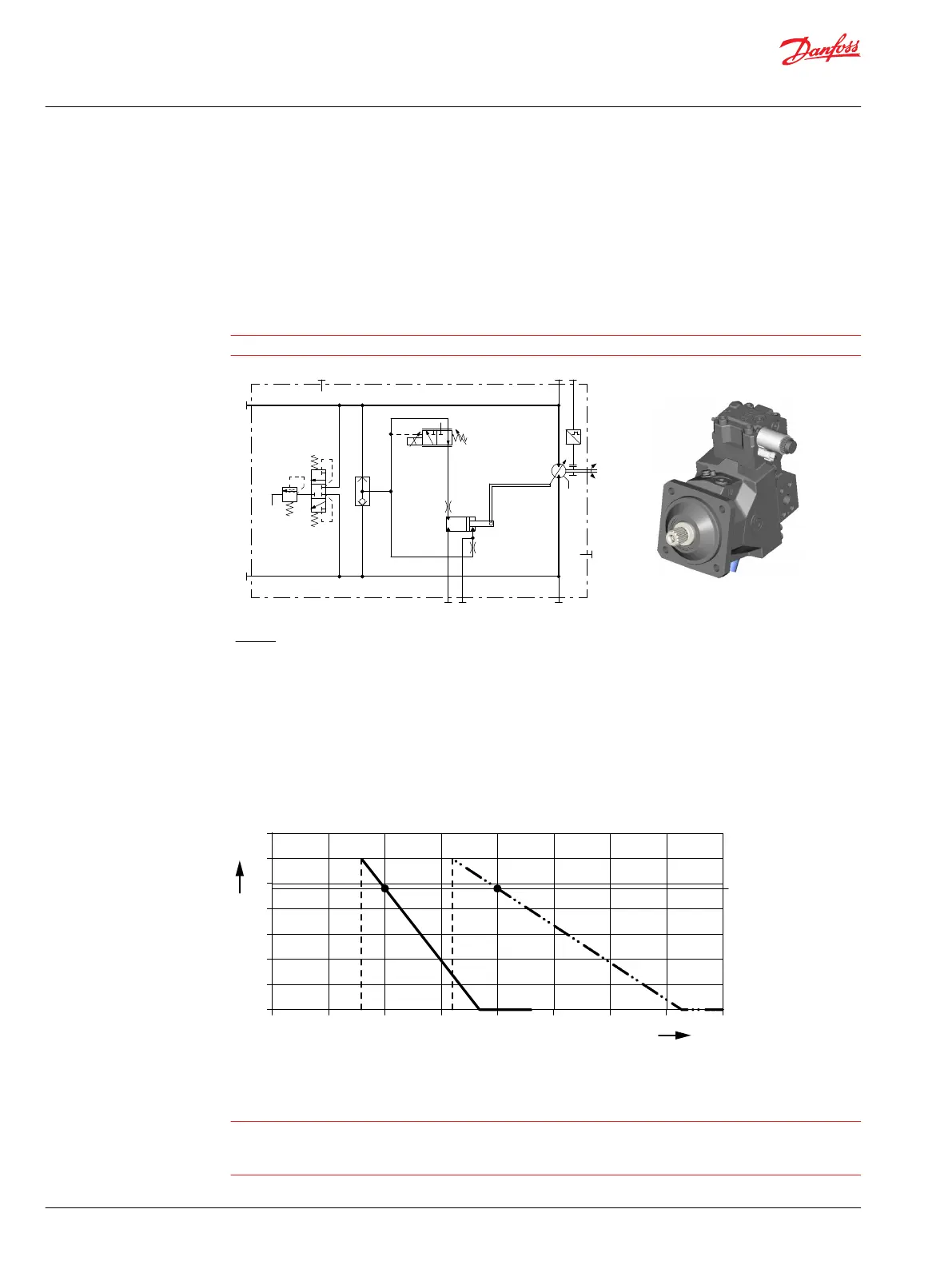

Options P1DA, P2DA – electric two-position control with PCOR

P1 – electric two-position control 12V/de-energized = min. displacement with electric prop. PCOR

12V

P2 – electric two-position control 24V/de-energized = min. displacement with electric prop. PCOR

24V

DA – with electric proportional PCOR / without Brake Pressure Defeat

Caution

This control is not for use in propel applications.

A

B

max

min

M4

L1

L2

N

P003456

n

MA

M5 MB

C6

Where:

A, B Main pressure lines

L1, L2 Drain lines

M4, M5 Gauge port servo pressure

MA, MB Gauge port system pressure

N Speed sensor (optional)

Options P1DA, P2DA

Solenoid C6

De-energized = min. displacement

Full-energized = max. displacement

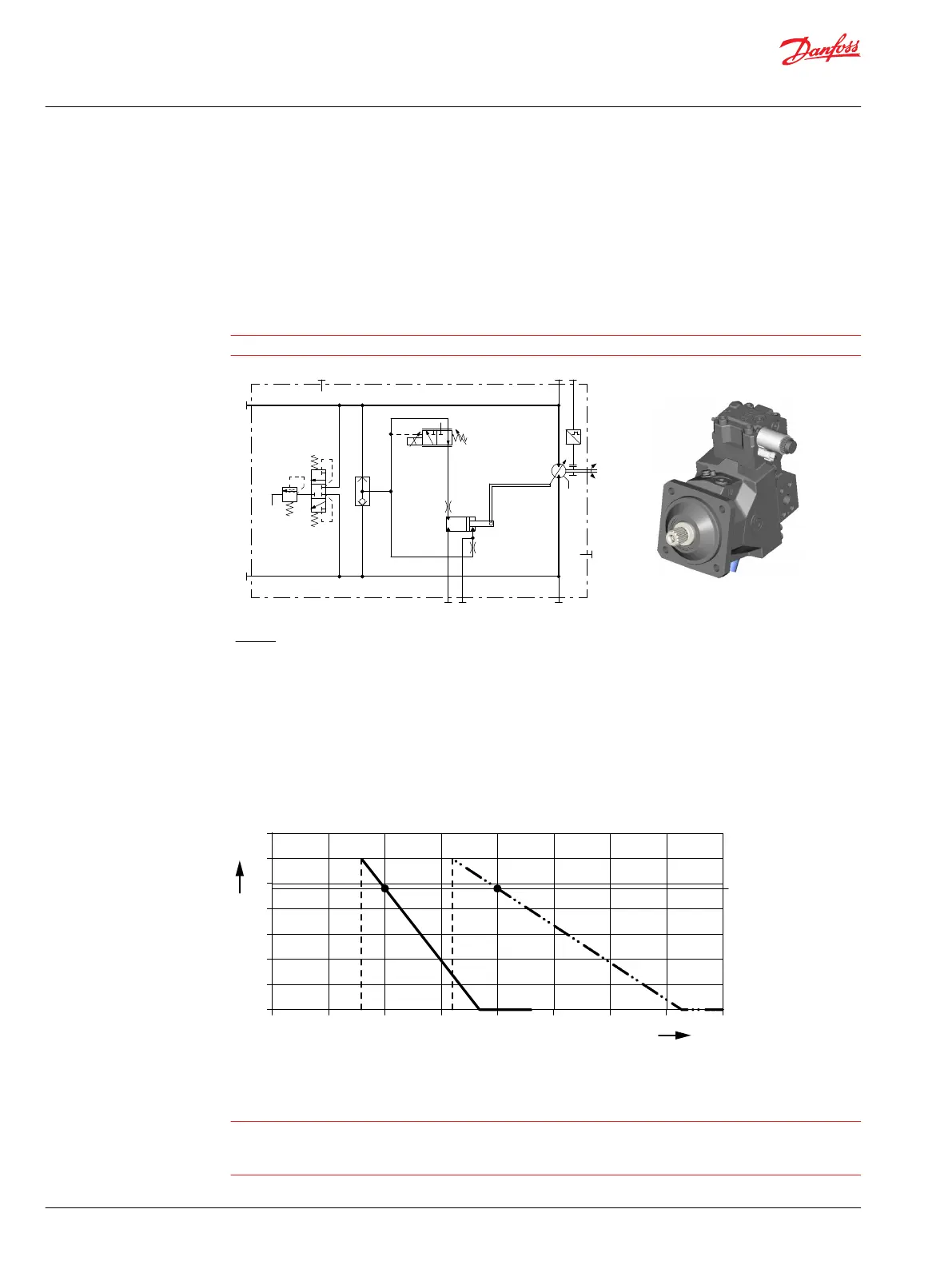

PCOR pressure (bar) versus Input command (mA)

0

50

100

150

200

250

240*

300

350

0 200 400 600 800 1000 1200 1400 1600

P003 485

bar

P1

P2

mA

Maximum PCOR setting = 300 bar [4351 psi], * Production test setting = 240 bar

Caution

If the signal to the PPCOR is lost or drops below the range shown in the chart, the PCOR setting will

potentially increase to pressure levels above the recommended application limits or the regulated

pressure control of the pump, and in effect, disable the PCOR function.

The PCOR pressure level can be proportionally changed with the input current to the solenoid.

Technical Information

H1 Bent Axis Variable Displacement Motors, Size 060/080/110/160/210/250

Controls – nomenclature, description

62 |

©

Danfoss | December 2016 11037153 | BC00000043en-US1103

Loading...

Loading...