H1 Pumps General Specification

Axial piston closed circuit variable displacement pumps of cradle swash-plate design with clockwise or

counterclockwise direction of rotation.

Pipe connections

•

Main pressure ports: ISO split flange boss

•

Main pressure ports H1P 045/053: SAE straight thread O-ring boss

•

Main pressure ports H1P 060/068: ISO split flange boss

•

Remaining ports: SAE straight thread O-ring boss

Recommended installation position

Pump installation position is discretionary, however the recommended control position is on the top or

at the side with the top position preferred. If the pump is installed with the control at the bottom,

flushing flow must be provided through port M14 located on the EDC, FNR and NFPE control.

Vertical input shaft installation is acceptable. If input shaft is at the top, 1 bar case pressure must be

maintained during operation. The housing must always be filled with hydraulic fluid. Recommended

mounting for a multiple pump stack is to arrange the highest power flow towards the input source.

Consult Danfoss for nonconformance to these guidelines.

Auxiliary cavity pressure

Auxiliary cavity pressure will be inlet pressure with internal charge pump or case pressure with external

charge supply. For reference see Operating Parameters. Please verify mating pump shaft seal capability.

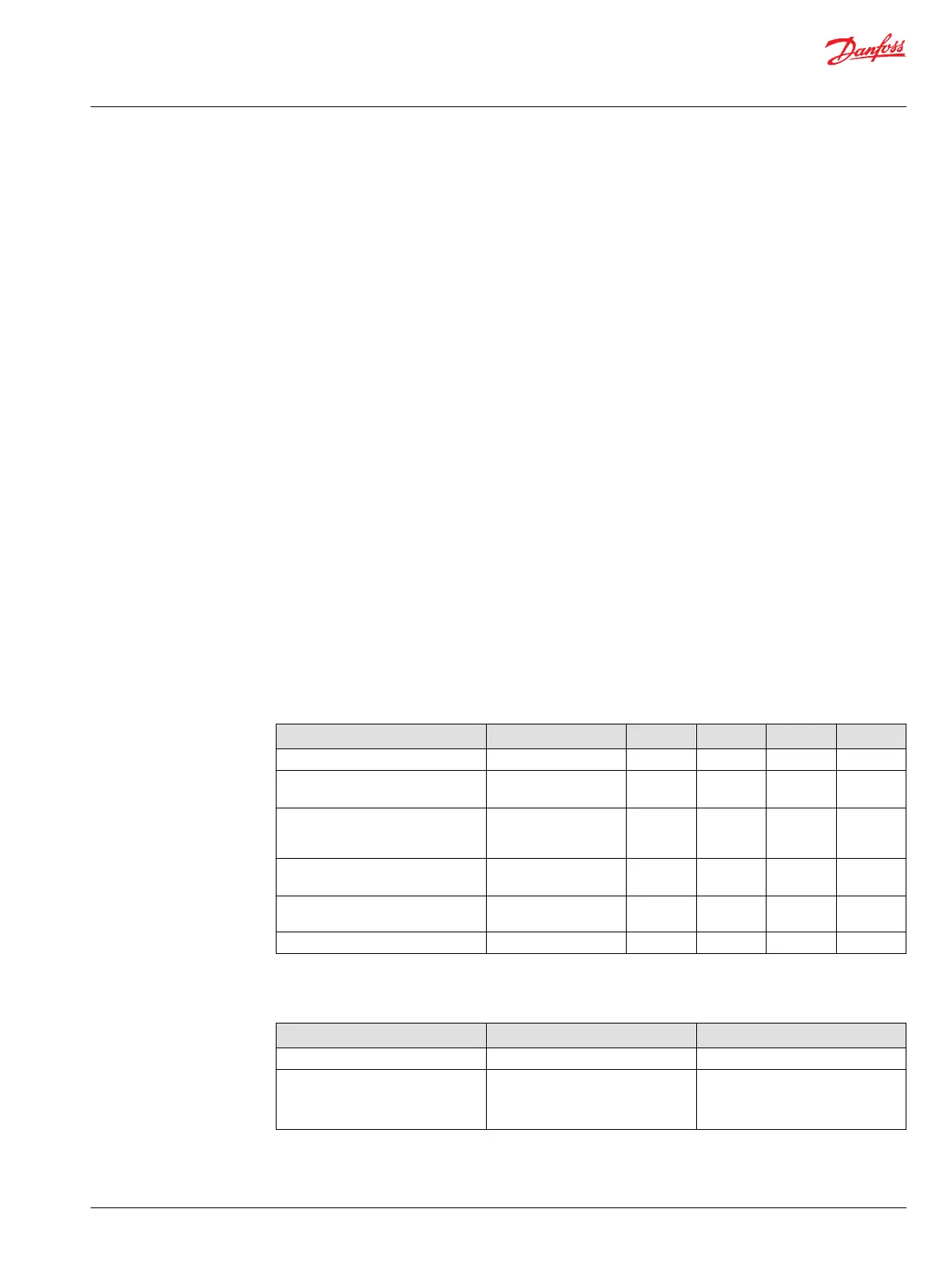

Technical Data for H1 Tandem Pumps

Technical Data

Feature Unit 045 053 060 068

Displacement cm

3

[in

3

] 45.0 [2.75] 53.8 [3.28] 60.4 [3.69] 68.0 [4.15]

Flow at rated (continuous) speed

*

l/min

[US gal/min]

153 [40] 183 [48] 210 [55.5] 238 [62.8]

Torque at maximum displacement

(theoretical)

N•m/bar

[lb•in/1000 psi]

0.8 [488] 0.9

[549]0.007

8 [0.00575]

0.96 [590] 1.08 [610]

Mass moment of inertia of rotating

components

kg•m

2

[slug•ft

2

]

0.0077

[0.00568]

0.0078

[0.00575

0.0143

[0.01055]

0.0143

[0.01052]

Mass (weight dry, without charge

pump or auxiliary flange)

kg [lb] 65 [143] 65 [143] 96.2 [212] 96.2 [212]

Oil volume l [US gal] 2.3 [0.61] 2.3 [0.61] 4.2 [1.1] 4.2 [1.1]

*

Applies for each rotating group.

Physical properties

Description 045/053 060/068

Mounting flange per ISO 3019-1 Flange 101-2 (SAE B), special bolt Flange 127-4 (SAE C)

Input shaft outer diameter, splines

per ISO 3019-1

•

Ø25 mm - 4 (SAE B-B, 15 teeth)

•

Ø32 mm - 4 (SAE-C, 14 teeth)

•

Ø31 mm - 4 (19 teeth)

•

Ø32 mm - 4 (SAE C, 14 teeth)

•

Ø35 mm - 4 (SAE C, 21 teeth)

Service Manual

H1T 045/053, 060/068 Axial Piston Tandem Pumps

Technical Specifications

©

Danfoss | September 2020 AX152886481761en-000405 | 27

Loading...

Loading...