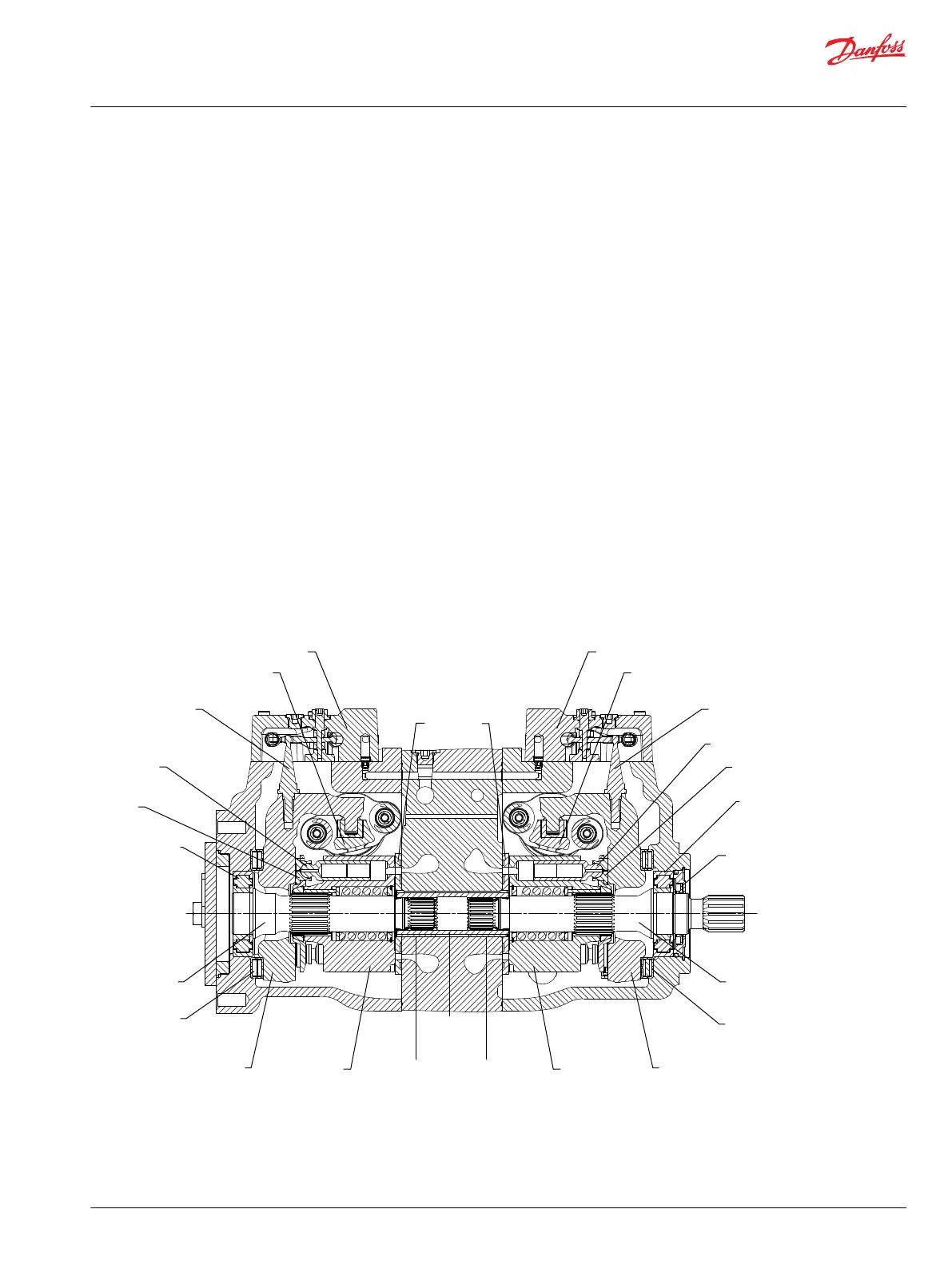

Tandem Pumps Design

Danfoss H1 tandem closed circuit piston pumps convert input torque to hydraulic power. The tandem

design powers two independent drive trains for dual-path propel applications.

The two-piece input shaft transmits rotational force to the cylinder block. A splined coupling connects

the front and rear shafts. Bearings at the front, rear, and center of the pump support the shaft. Splines

connect each shaft to a cylinder block. A lip-seal at the front end of the pump prevents leakage where the

shaft exits the pump housing. The spinning cylinder block contains nine reciprocating pistons. Each

piston has a brass slipper connected at one end by a ball joint. The block spring, ball guide, and slipper

retainer hold the slippers to the swashplate. The reciprocating movement of the pistons occurs as the

slippers slide against the inclined swashplates during rotation.

Via the valve plates, one half of each cylinder block is connected to port A or C and the other half to port

B or D. Front and rear sections have independent porting in the center section. As each piston cycles in

and out of its bore, fluid is drawn from one port and displaced to the other thereby imparting hydraulic

power into the system. A small amount of fluid is allowed to flow from the cylinder block/valve plate and

slipper/swashplate interfaces for lubrication and cooling. Case drain ports return this fluid to the

reservoir. An external charge pump (not shown) provides clean, cool fluid to makeup this lubricating flow

and to maintain minimum loop pressure.

The angle of each swashplate controls the volume and direction of fluid displaced into the system. The

servo pistons control the angle of the swashplates. Each pump control, by varying the pressure at the

servo pistons, controls each piston’s position. An electric signal to the control coils transmits the

command from the operator to the pump. Mechanical feedback of the swashplate position to the control

through the feedback pins allows for very precise displacement control and increases overall system

stability. Non-feedback control options do not use the mechanical feedback link.

Cross section view

P106 146E

Slipper

Piston

Cylinder block

Swashplat e

Rear shaft

Electric displacement control

Servo piston

Valve plates

Shaft coupling

Swashplate feedback pin

Front sha ft

Electric displacement control

Servo piston

Swashplate feedback pin

Piston

Slipper

Shaft seal

Swashplat e

Cylinder block

Swashplate bearing

Swashplate bearing

Front shaft bearing

Center shaft bearings

Rear shaft bearing

Service Manual

H1T 045/053, 060/068 Axial Piston Tandem Pumps

Introduction

©

Danfoss | September 2020 AX152886481761en-000405 | 9

Loading...

Loading...