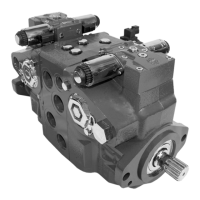

Servo and system pressure gauge port locations (060/068)

P109555

C

D

A

B

M4

M5

MD

MA

MB

MC

M4

M3

AM3

M5

AM3

Legend: Ports per ISO 11926–1

A, B, C, D System port: Split flange M12 x 1.5

MA, MB, MC, MD System gauge port:

9

/

16

–18

M3, AM3 Charge port:

9

/

16

–18

M4, M5 Servo gauge port:

7

/

16

–20

X7 Brake gauge port:

3

/

4

–16

E300 Servo cylinder clamp

E350 Servo cylinder clamp bolt

1. Run prime mover at 1800 min

-1

(rpm).

2. If using a PWM signal, ensure the signal is off.

3. Check the servo pressure gauges, ensure the differential between M4 and M5 is less than 2.5 bar [36

psi].

4. Using a 3/4 in deep socket, unthread both servo cylinders 2-3 turns.

This step ensures the servo cylinders have no contact with the servo piston.

5. Stroke the pump by turning the control eccentric screw (or supplying current to solenoid C1) until the

servo pressure at port M4 is 1 to 2 bar [14– 29 psi] greater than at port M5 and the system pressure

gauges indicate displacement.

Pressure should be greater at port MA for clockwise rotation, or MB for counterclockwise rotation.

This also indicates the servo piston is in contact with the servo cylinder on side M5.

Service Manual

H1T 045/053, 060/068 Axial Piston Tandem Pumps

Adjustments

54 |

©

Danfoss | September 2020 AX152886481761en-000405

Loading...

Loading...