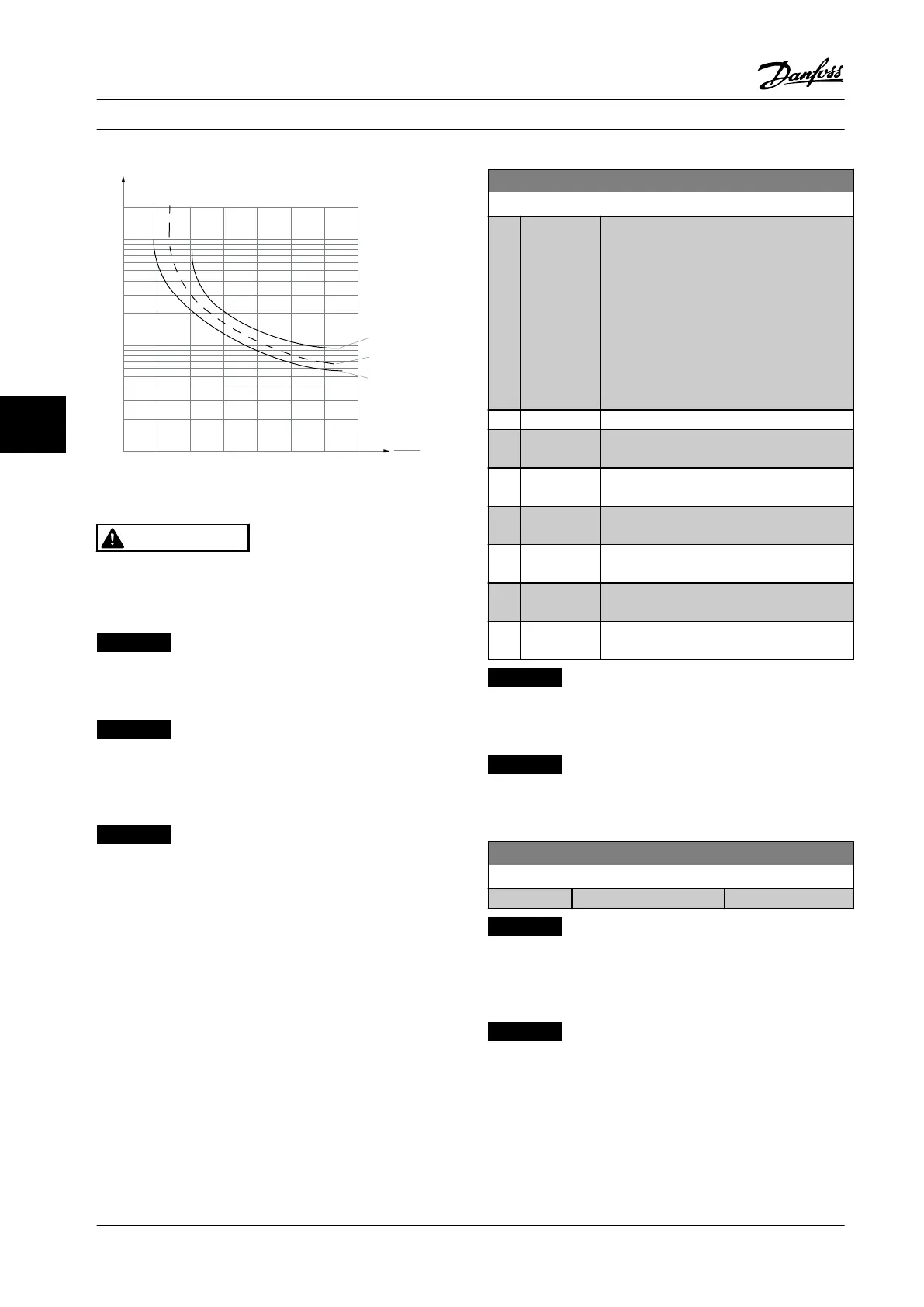

1.21.0 1.4

30

10

20

100

60

40

50

1.81.6 2.0

2000

500

200

400

300

1000

600

t [s]

175ZA052.11

fOUT = 0.2 x f M,N

fOUT = 2 x f M,N

fOUT = 1 x f M,N

IMN

IM

Figure 6.9

WARNING

In order to maintain PELV, all connections made to the

control terminals must be PELV, e.g., thermistor must be

reinforced/double-insulated.

NOTICE!

Danfoss recommends using 24 V DC as thermistor supply

voltage.

NOTICE!

The ETR timer function does not work when

parameter 1-10 Motor Construction = [1] PM, non-salient

SPM.

NOTICE!

For correct operation of ETR function, setting in

parameter 1-03 Torque Characteristics must t the

application (see description of parameter 1-03 Torque

Characteristics).

1-93 Thermistor Source

Option: Function:

Select the input to which the thermistor (PTC

sensor) should be connected. An analog

input option [1] or [2] cannot be selected if

the analog input is already in use as a

reference source (selected in

parameter 3-15 Reference 1 Source,

parameter 3-16 Reference 2 Source or

parameter 3-17 Reference 3 Source ).

When using MCB 112, choice [0] None must

always be selected.

[0] * None

[1] Analog Input

53

[2] Analog Input

54

[3] Digital input

18

[4] Digital input

19

[5] Digital input

32

[6] Digital input

33

NOTICE!

This parameter cannot be adjusted while the motor is

running.

NOTICE!

Digital input should be set to [0] PNP - Active at 24 V in

parameter 5-00 Digital I/O Mode.

2-00 DC Hold/Preheat Current

Range: Function:

50 %* [ 0 - 160 %]

NOTICE!

Parameter 2-00 DC Hold/Preheat Current will not have

eect when parameter 1-10 Motor Construction = [1] PM,

non-salient SPM.

NOTICE!

The maximum value depends on the rated motor

current.

Avoid 100% current for too long. It may damage the

motor.

How to Program

VLT

®

HVAC Drive FC 102

90 Danfoss A/S © 08/2014 All rights reserved. MG11F522

66

Loading...

Loading...