APPLICATION GUIDELINES

18

FRCC.PC.007.B5.02

ELECTRICAL DATA, CONNECTIONS AND WIRING

Winding resistance is the resistance between

phases at 25°C (resistance value +/- 7%).

Winding resistance is generally low and it requires

adapted tools for precise measurement. Use a dig-

ital ohm-meter, a "4 wires" method and measure

under stabilised ambient temperature. Winding

resistance varies strongly with winding tempera-

ture ; if the compressor is stabilised at a diff erent

value than 25°C, the measured resistance must be

corrected with following formula:

a + t

amb

R

tamb

= R

25°C

_______

a + t

25°C

t

25°C

: reference temperature = 25°C

t

amb

: temperature during measurement (°C)

R

25°C

: winding resistance at 25°C

R

amb

: winding resistance at t

amb

Coeffi cient a = 234.5

The max. operating current is the current when

the compressors operates at maximum load con-

ditions and 10% below nominal voltage (+15°C

evaporating temperature and +68°C condensing

temperature).

Max Oper. A can be used to select cables and

contactors.

In normal operation, the compressor current

consumption is always less than the Max Oper. A.

value.

The MCC is the current at which the motor pro-

tection trips under maximum load and low volt-

age conditions. This MCC value is the maximum

at which the compressor can be operated in tran-

sient conditions and out of the application enve-

lope. Above this value, the internal motor protec-

tion or external electronic module will cut-out the

compressor to protect the motor.

Locked Rotor Amp value is the higher average

current as measured on mechanically blocked

compressor tested under nominal voltage. The

LRA value can be used as rough estimation for the

starting current. However in most cases, the real

starting current will be lower. A soft starter can be

applied to reduce starting current.

Winding resistance

Max. operating Current

MCC (Maximum Continuous

Current)

LRA (Locked Rotor Amp)

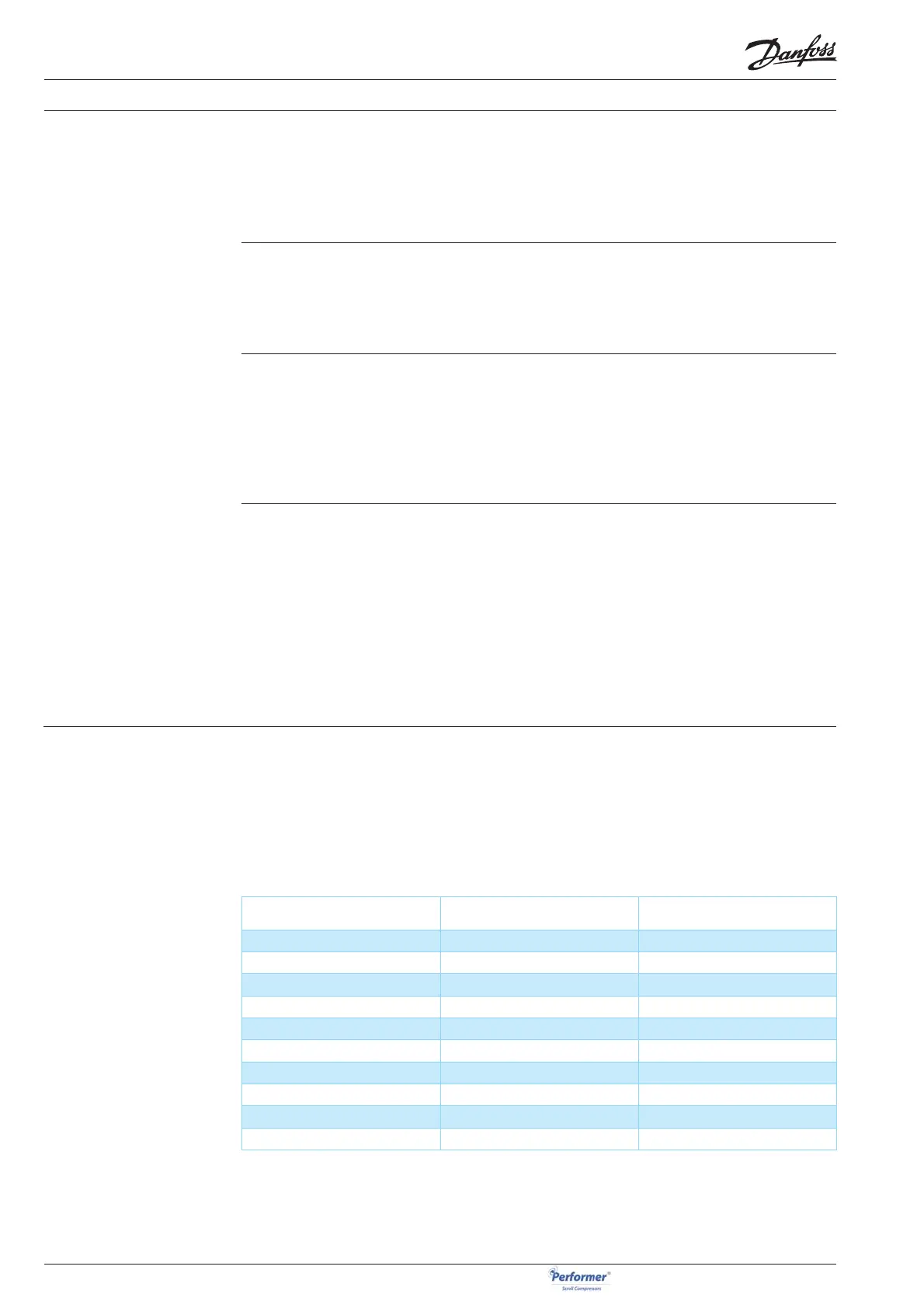

The inrush current for the Performer® SH scroll

compressors with motor code 4 (400V /3ph /

50Hz or 460V / 3ph / 60Hz) can be reduced using

the Danfoss digitally-controlled MCI compressor

soft starter. MCI soft starters are designed to re-

duce the starting current of 3-phase AC motors;

they can reduce the inrush current by up to 40%,

thereby eliminating the detrimental eff ects of

high starting torque surges and costly demand

charges from the resultant current spike. Upon

starting, the controller gradually increases the

voltage supplied to the motor until full-line volt-

age has been reached. All settings, such as ramp-

up time (less than 0.5 sec) and initial torque, are

preset and do not require modifi cation.

Danfoss MCI

soft-start controller

Compressor model

Soft start reference

Ambient max. 40°C

Soft start reference

Ambient max. 55°C

SH090 MCI15C MCI15C

SH105 MCI25C MCI25C

SH120 MCI25C MCI25C

SH140 MCI25C MCI25C *

SH161 MCI25C MCI25C *

SH184 MCI25C MCI25C *

SH180 MCI50CM MCI50CM

SH240 MCI50CM MCI50CM *

SH300 MCI50CM * MCI50CM *

SH380 MCI50CM * MCI50CM *

* by pass contactor K1 is required

Loading...

Loading...