APPLICATION GUIDELINES

42

FRCC.PC.007.B5.02

INSTALLATION

When brazing the compressor fi ttings, do not

overheat the compressor shell, which could se-

verely damage certain internal components due

to excessive heating. Use of a heat shield and/

or a heat-absorbent compound is highly recom-

mended. Due to the relatively sizable tubing and

fi tting diameters a double-tipped torch using

acetylene is recommended for brazing operation

on SH compressors.

For rotolock version compressors, solder sleeves

are available.

For brazing the suction and discharge connec-

tions, the following procedure is advised:

y

.Make sure that no electrical wiring is connected

to the compressor.

y

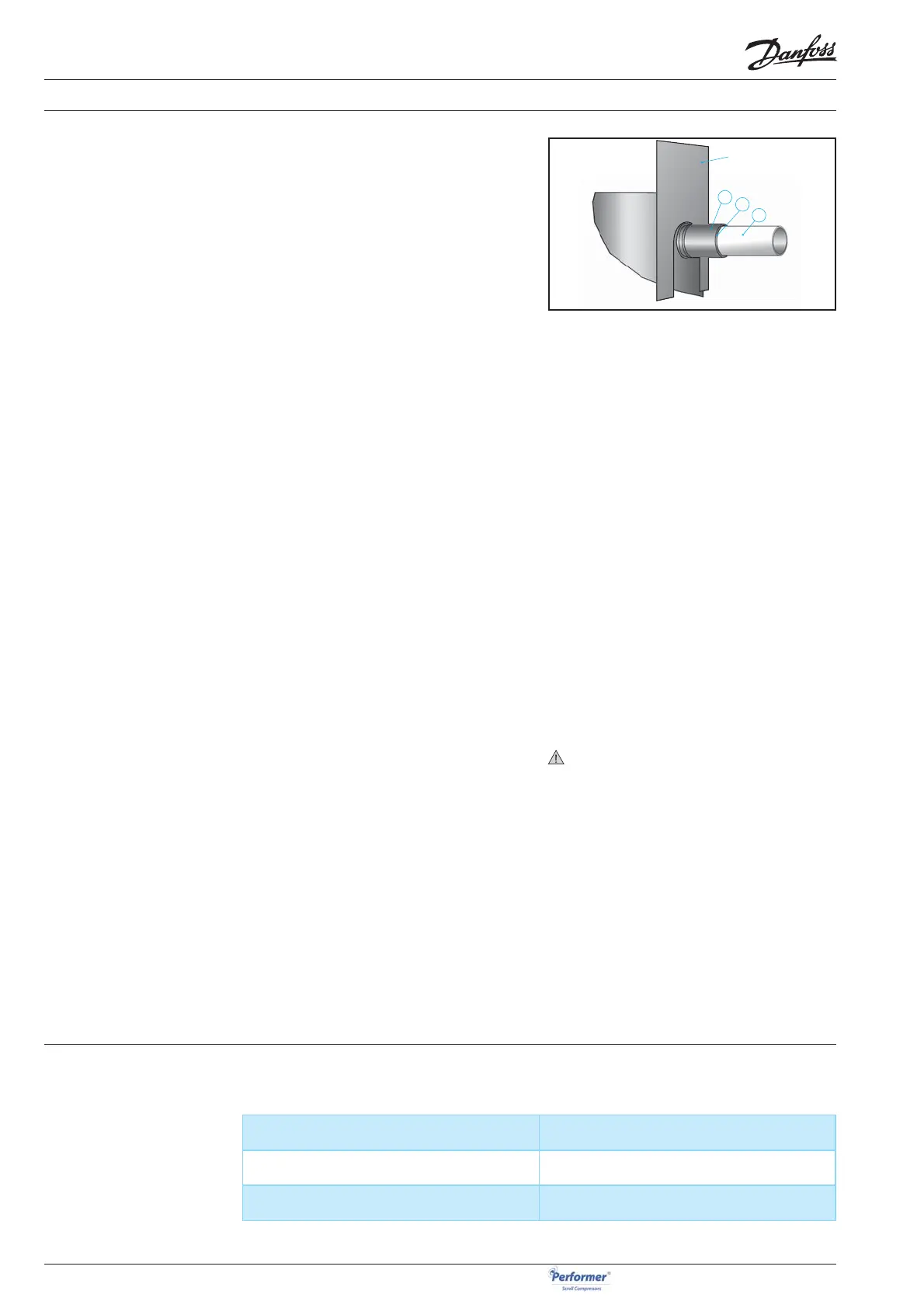

.Protect the terminal box and compressor

painted surfaces from torch heat damage (see

diagram).

y

.Remove the Tefl on gaskets when brazing ro-

tolock connectors with solder sleeves.

y

.Use only clean refrigeration-grade copper tub-

ing and clean all connections.

y

.Use brazing material with a minimum of 5% sil-

ver content.

y

.Purge nitrogen or CO

2

through the compres-

sor in order to prevent against oxidation and

fl ammable conditions. The compressor should

not be exposed to the open air for extended

periods.

y

.Use of a double-tipped torch is recommended.

y

.Apply heat evenly to area until the brazing

temperature is reached. Move the torch to area

and apply heat evenly until the brazing tem-

perature has been reached there as well, and

then begin adding the brazing material. Move

the torch evenly around the joint, in applying

only enough brazing material to fl ow the full cir-

cumference of the joint.

y

.Move the torch to area only long enough to

draw the brazing material into the joint, but not

into the compressor.

y

.Remove all remaining fl ux once the joint has

been soldered with a wire brush or a wet cloth.

Remaining fl ux would cause corrosion of the

tubing.

Ensure that no fl ux is allowed to enter into the

tubing or compressor. Flux is acidic and can cause

substantial damage to the internal parts of the

system and compressor.

The polyolester oil used in SH compressors is

highly hygroscopic and will rapidly absorb mois-

ture from the air. The compressor must therefore

not be left open to the atmosphere for a long pe-

riod of time. The compressor fi tting plugs shall be

removed just before brazing the compressor. The

compressor should always be the last component

brazed into the system

Before eventual unbrazing the compressor or

any system component, the refrigerant charge

must be removed from both the high- and low-

pressure sides. Failure to do so may result in se-

rious personal injury. Pressure gauges must be

used to ensure all pressures are at atmospheric

level.

For more detailed information on the appropriate

materials required for brazing or soldering, please

contact the product manufacturer or distribu-

tor. For specifi c applications not covered herein,

please contact Danfoss for further information.

Compressor connection

System pressure test Always use an inert gas such as nitrogen for pres-

sure testing. Never use other gasses such as oxy-

gen, dry air or acetylene as these may form an in-

fl ammable mixture. Do not exceed the following

pressures:

B

C

A

heat shield

Maximum compressor test pressure (low side)

30.2 bar (g) for SH180 to 380

33.3 bar(g) for SH090 to 184

Maximum compressor test pressure (high side) 45 bar (g)

Maximum pressure diff erence between high & low side

of the compressor

37 bar

Loading...

Loading...