APPLICATION GUIDELINES

28

FRCC.PC.007.B5.02

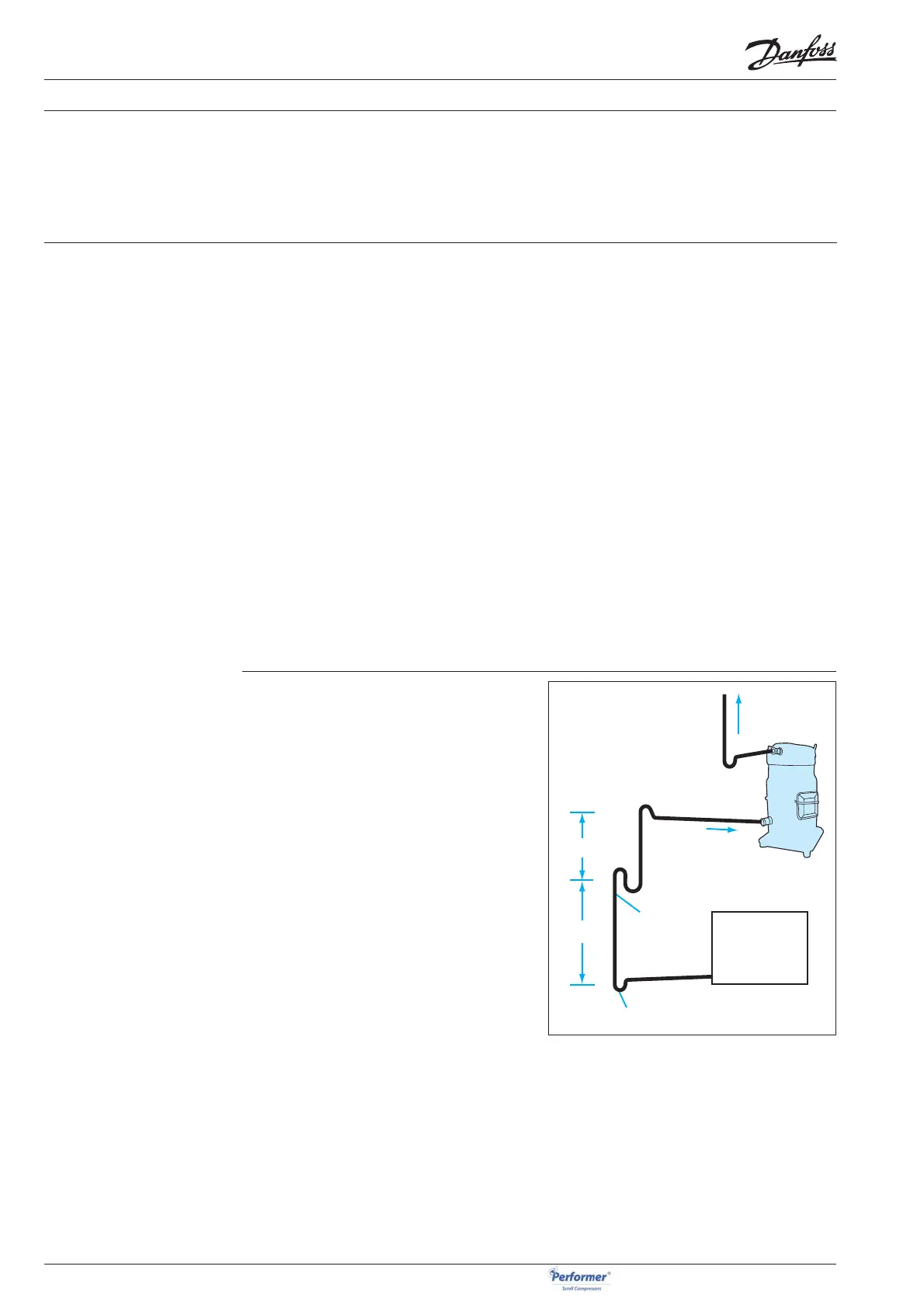

If the evaporator lies above the compressor, as

is often the case in split or remote condenser

systems, the addition of a pump-down cycle is

strongly recommended. If a pump-down cycle

were to be omitted, the suction line must have a

loop at the evaporator outlet to prevent refriger-

ant from draining into the compressor during off -

cycles.

If the evaporator were situated below the com-

pressor, the suction riser must be trapped so as

to prevent liquid refrigerant from collecting at the

outlet of the evaporator while the system is idle,

which would mislead the expansion valve’s sen-

sor (thermal bulb) at start-up.

SYSTEM DESIGN RECOMMENDATIONS

The working pressure in systems with R410A is

about 60% higher than in systems with R22 or

R407C. Consequently, all system components and

piping must be designed for this higher pressure

level.

Proper piping practices should be employed to

ensure adequate oil return, even under minimum

load conditions with special consideration given

to the size and slope of the tubing coming from

the evaporator. Tubing returns from the evapora-

tor should be designed so as not to trap oil and to

prevent oil and refrigerant migration back to the

compressor during off -cycles.

In systems with R410A, the refrigerant mass fl ow

will be lower compared to R22/R407C systems.

To maintain acceptable pressure drops and ac-

ceptable minimum gas velocities, the refrigerant

piping must be reduced in size compared to R22

/ R407C systems. Take care not to create too high

pressure drops or since in R410A systems the neg-

ative impact of high pressure drops on the system

effi ciency is stronger than in R22/R407C systems.

Piping should be designed with adequate three-

dimensional fl exibility. It should not be in contact

with the surrounding structure, unless a proper

tubing mount has been installed. This protection

proves necessary to avoid excess vibration, which

can ultimately result in connection or tube failure

due to fatigue or wear from abrasion. Aside from

tubing and connection damage, excess vibration

may be transmitted to the surrounding structure

and generate an unacceptable noise level within

that structure as well. For more information on

noise and vibration, see the section on: «Sound

and vibration management».

Successful application of scroll compressors is

dependent on careful selection of the compres-

sor for the application. If the compressor is not

correct for the system, it will operate beyond the

limits given in this manual. Poor performance, re-

duced reliability, or both may result.

Essential piping design

considerations

General

Suction lines

HP

4 m/s or more

0.5% slope

To condenser

max. 4 m

max. 4 m

0.5% slope

U-trap, as short as possible

U-trap

4m/s or more

U trap, as short as possible

Evaporator

LP

8 to 12 m/s

Loading...

Loading...