APPLICATION GUIDELINES

30

FRCC.PC.007.B5.02

SYSTEM DESIGN RECOMMENDATIONS

Off -cycle migration Off -cycle refrigerant migration is likely to occur

when the compressor is located at the coldest

part of the installation, when the system uses a

bleed-type expansion device, or if liquid is al-

lowed to migrate from the evaporator into the

compressor sump by gravity. If too much liquid

refrigerant accumulates in the sump it will satu-

rate the oil and lead to a fl ooded start: when the

compressor starts running again, the refrigerant

evaporates abruptly under the sudden decrease

of the bottom shell pressure, causing the oil to

foam. In extreme situations, this might result

in liquid slugging (liquid entering the scroll ele-

ments), which must be avoided as it causes irre-

versible damage to the compressor.

Performer® SH scroll compressors can tolerate oc-

casional fl ooded starts as long as the total system

charge does not exceed the maximum compres-

sor refrigerant charge.

A suitable test to evaluate the risk of off -cycle mi-

gration is the following:

Stabilize the non running system at 5°C ambi-•

ent temperature,

Raise the ambient temperature to 20°C and •

keep it for 10 minutes,

Start the compressor and monitor sump tem-•

perature, sight glass indication and sound

level.

The presence of liquid in the crankcase can be eas-

ily detected by checking the sump level through

the oil sight glass. Foam in the oil sump indicates

a fl ooded start.

A noisy start, oil loss from the sump and sump cool

down are indications for migration. Depending

on the amount of migration graduate measures

shall be taken:

Sump heater•

Liquid line solenoid valve•

Pump down cycle•

More detailed information can be found in the paragraphs hereafter.

Please contact Danfoss Technical Support for any deviation from these guidelines.

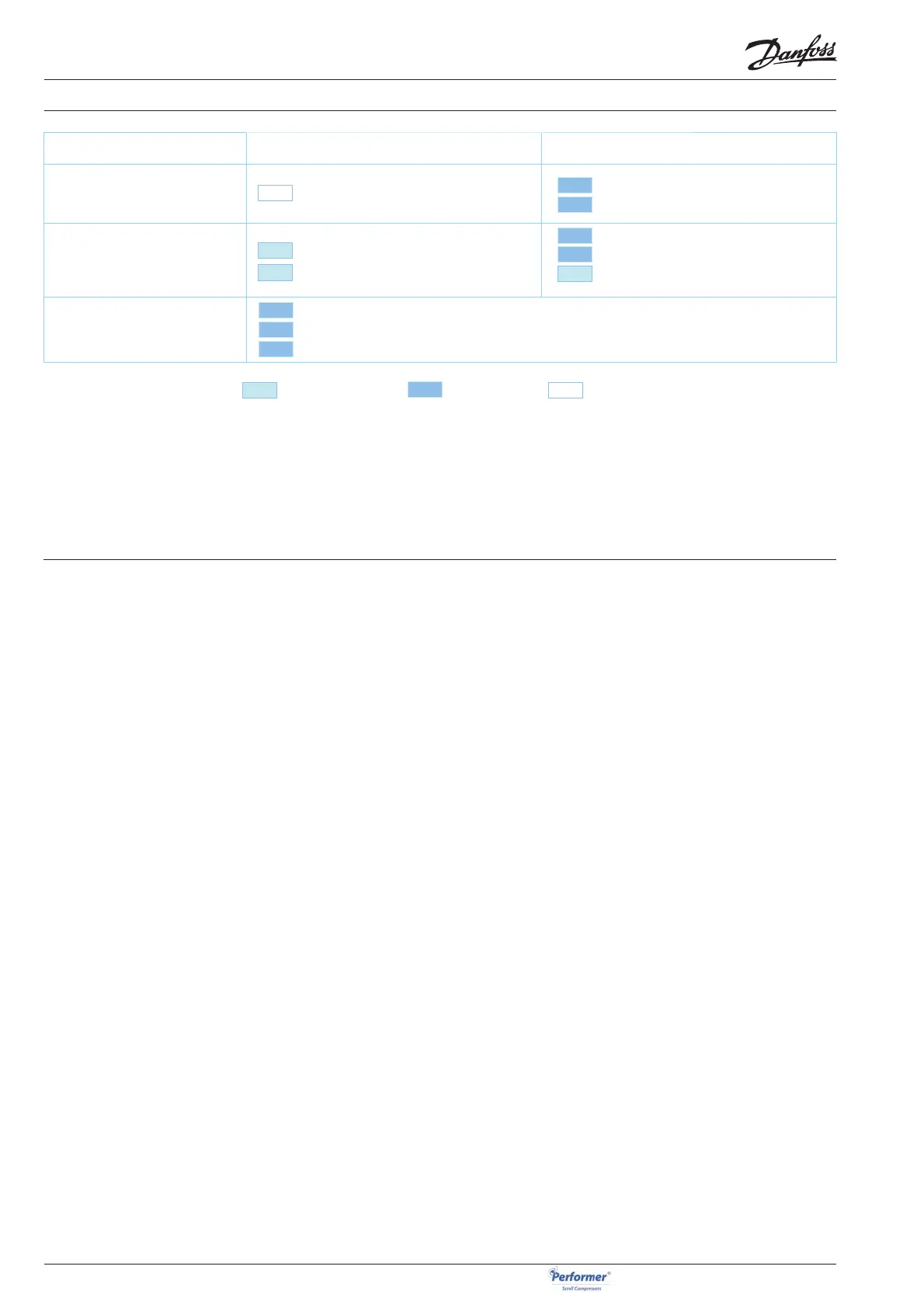

BELOW charge limit ABOVE charge limit

Cooling only systems,

Packaged units

No test or additional safeties required

Refrigerant migration & fl ood back test

Sump heater

Cooling only systems

with remote condenser

and split system units

Refrigerant migration & fl ood back test

Sump heater

Refrigerant migration & fl ood back test

Sump heater

Liquid receiver (in association with LLSV and

pump down)

Reversible heat pump system

Specifi c tests for repetitive fl ood back

Sump heater

Defrost test For more details, refer to section "Reversible heat pump system"

Recommended Required No test or additional safeties required

Note: for special conditions such as low ambient temperature, low refrigerant load or brazed plate heat exchangers please refer to

corresponding sections.

REC

REC

REQ

REQ

REQ

REQ

REQ

REQ

REQ

REQ

REC

REC

9

9

Loading...

Loading...