APPLICATION GUIDELINES

FRCC.PC.007.B5.02

27

Cycle rate limit

A low-pressure (LP) safety switch must be used.

Deep vacuum operations of a scroll compressor

can cause internal electrical arcing and scroll in-

stability. Performer SH Scroll compressors exhibit

high volumetric effi ciency and may draw very low

vacuum levels, which could induce such a prob-

lem. The minimum low-pressure safety switch

(loss-of-charge safety switch) setting is given in

the following table. For systems without pump-

down, the LP safety switch must either be a man-

ual lockout device or an automatic switch wired

into an electrical lockout circuit. The LP switch

tolerance must not allow for vacuum operations

of the compressor. LP switch settings for pump-

down cycles with automatic reset are also listed

in the table below.

Low pressure

OPERATING CONDITIONS

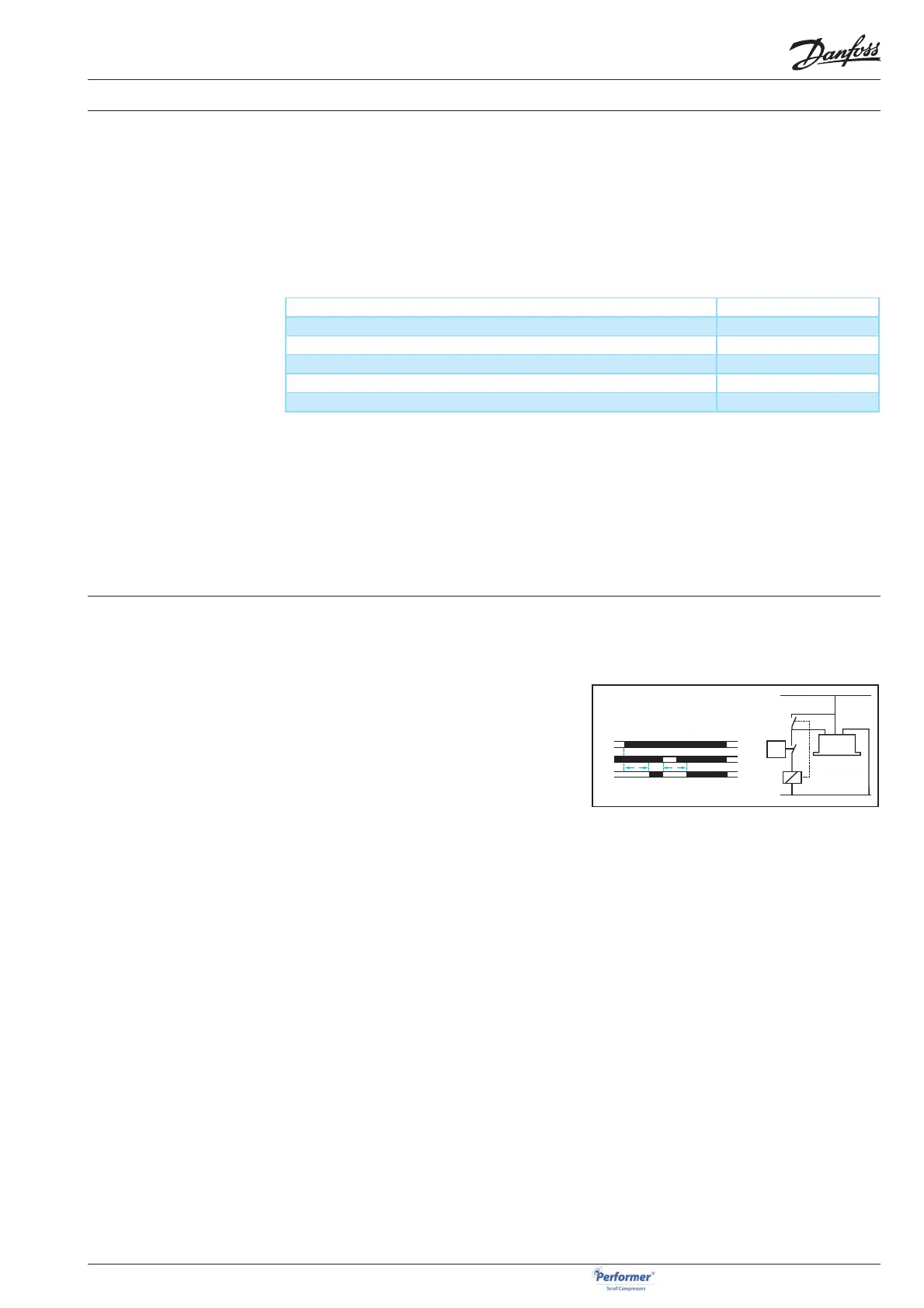

Danfoss recommends a restart delay timer to limit

compressor cycling. The timer prevents reverse

compressor rotation, which may occur during

brief power interruptions.

The system must be designed in a way that guar-

antees a minimum compressor running time of 2

minutes so as to provide for suffi cient motor cool-

ing after start-up along with proper oil return.

Note that the oil return may vary since it depends

upon system design.

There must be no more than 12 starts per hour, a

number higher than 12 reduces the service life of

the motor-compressor unit. A three-minute (180-

sec) time out is recommended.

Note that these two diff erent low pressure switch-

es also require diff erent settings. The low pressure

pump down switch setting must always be within

the operating envelope, for example 2.3 bar for

R410A. The compressor can be operated full time

under such condition. The minimum low pressure

safety switch setting may be outside the normal

operating envelope and should only be reached

in exceptional (emergency) situations, for exam-

ple 1.5 bar for R410A.

Please contact Danfoss Technical Support for any deviation from this guidelines.

T T

TH

H

KA

A1

A2 A3A1

180 s

A2

KA

~

~

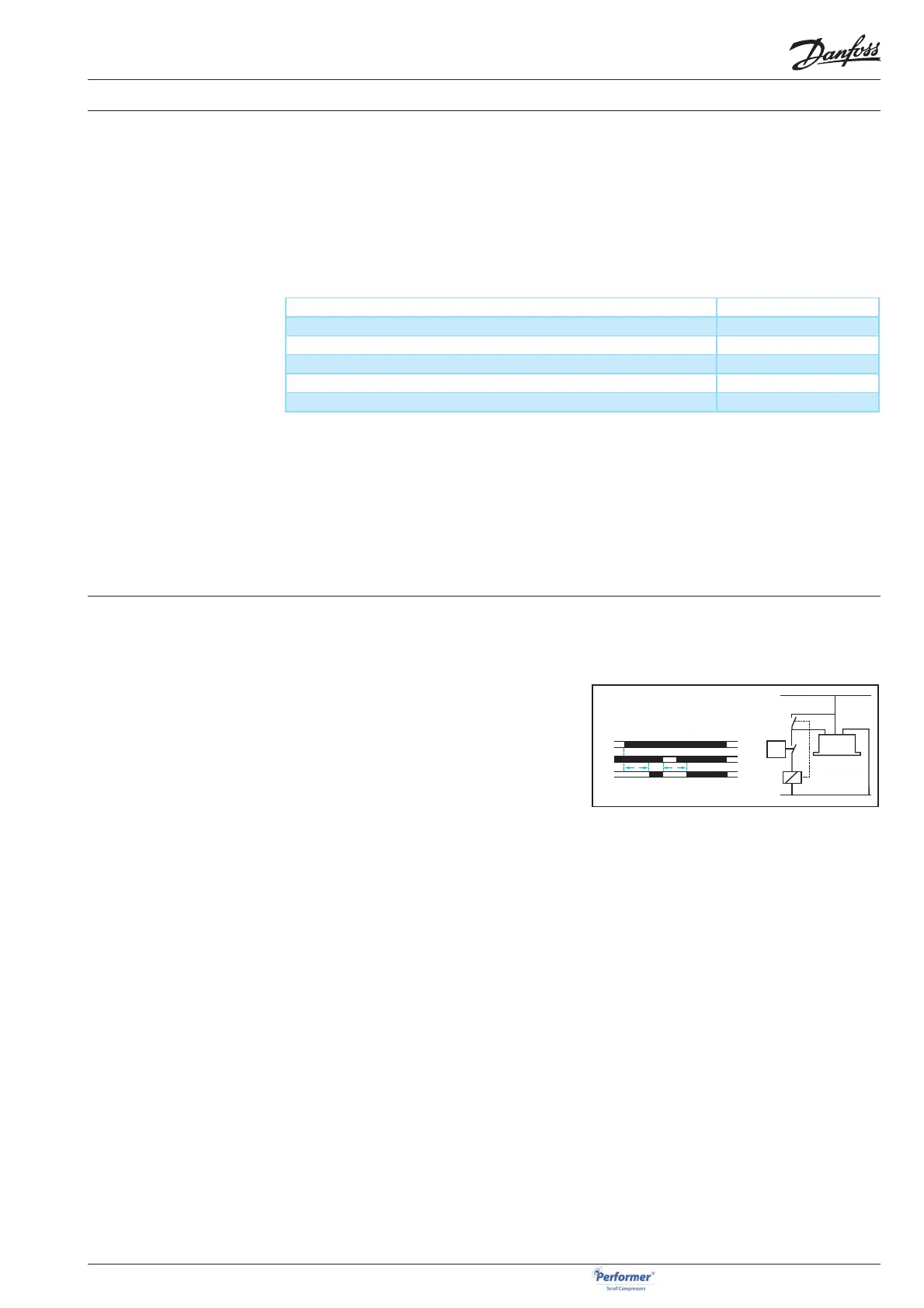

Pressure settings R410A

Working pressure range high side bar (g) 13.5 - 44.5

Working pressure range low side bar (g) 2.3 - 11.6

Maximum high pressure safety switch setting bar (g) 45

Minimum low pressure safety switch setting * bar (g) 1.5

Minimum low pressure pump-down switch setting ** bar (g) 2.3

* LP safety switch shall never be bypassed and shall have no time delay.

** Recommended pump-down switch settings: 1.5 bar below nominal evap. pressure with minimum of 2.3 bar(g)

Loading...

Loading...