APPLICATION GUIDELINES

FRCC.PC.007.B5.02

21

ELECTRICAL DATA, CONNECTIONS AND WIRING

Motor protection

Compressor models SH090-105-120-140-161

-184 have been provided with an internal over-

load motor protection to prevent against exces-

sive current and temperature caused by overload-

ing, low refrigerant fl ow or phase loss. The cutout

current is the MCC value listed in section "Three

phase electrical characteristics".

The protector is located in the star point of the

motor and, should it be activated, will cut out all

three phases. It will be reset automatically.

While not compulsory, an additional external

overload is still advisable for either alarm or man-

ual reset.

Then it must be set below MCC value (at max op-

erating current:

when the motor temperature is too high, •

then the internal protector will trip

when the current is too high the external •

overload protection will trip before the in-

ternal protection therefore off ering possibil-

ity of manual reset.

Compressor models SH180-240-300-380 are

delivered with a pre installed motor protection

module inside the terminal box. This device pro-

vides for effi cient and reliable protection against

overheating and overloading (as well as phase

loss/reversal on SH240-300-380).

The motor protector comprises a control module

and PTC sensors embedded in the motor winding.

The close contact between thermistors and wind-

ings ensures a very low level of thermal inertia.

The motor temperature is being constantly

measured by a PTC thermistor loop connected

on S1-S2 (called 1-2 on SH180). If any thermistor

exceeds its response temperature, its resistance

increases above the trip level (4,500 Ω) and the

output relay then trips – i.e. contacts M1-M2 (or

11-14 for SH180) are open. After cooling to below

the response temperature (resistance < 2,750 Ω),

a 5-minute time delay is activated. After this delay

has elapsed, the relay is once again pulled in – i.e.

contacts M1-M2 (11-14 for SH180) are closed. The

time delay may be cancelled by means of reset-

ting the mains (L-N -disconnect) for approximate-

ly 5 sec.

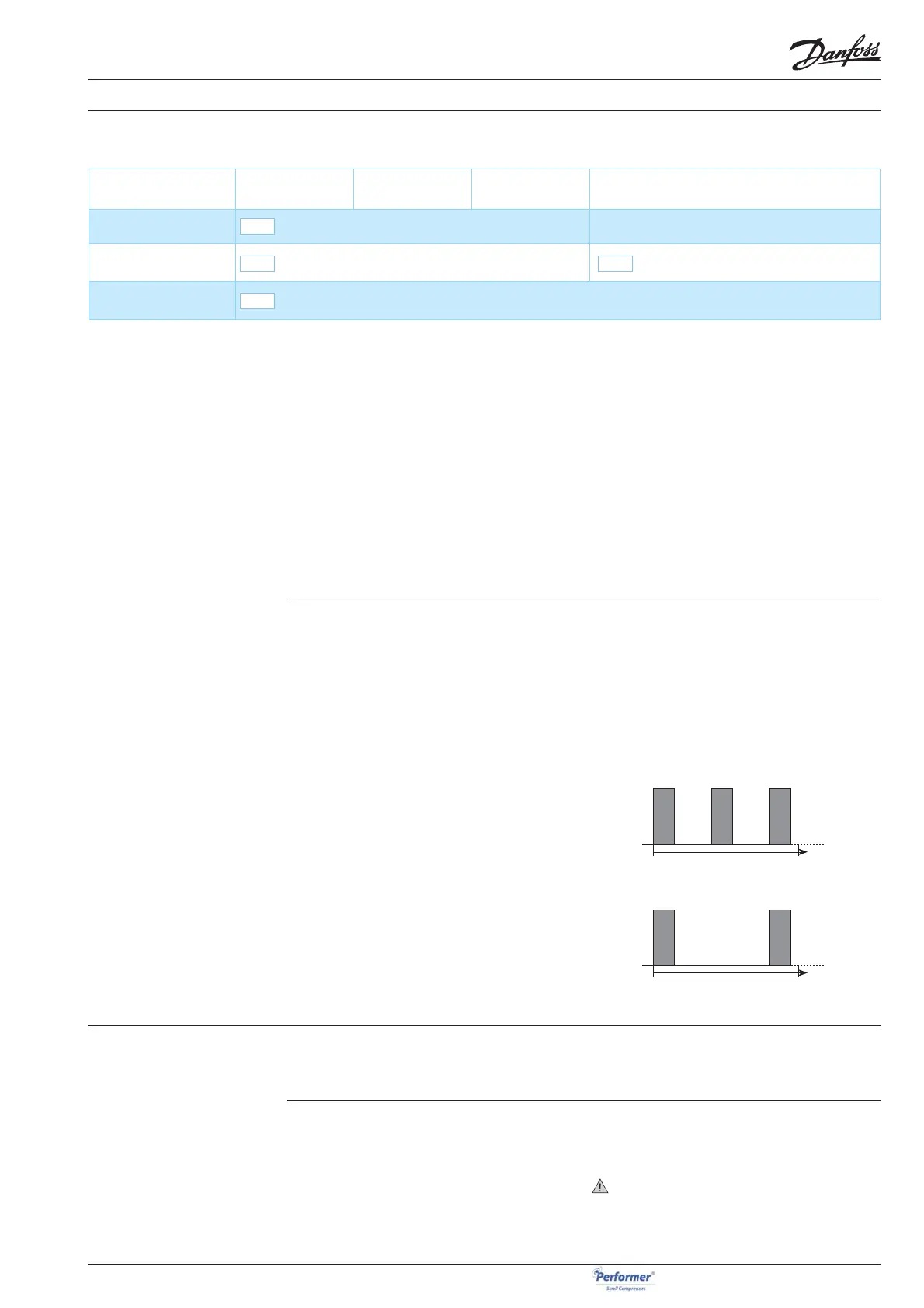

When present, the LED on module will lighten as

follows in case of overheat:

PTC overheat

Appr. 1 second

Delay timer active (after PTC over temp.)

Appr. 1 second

Use a phase meter to establish the phase orders

and connect line phases L1, L2 and L3 to terminals

T1, T2 and T3, respectively. The compressor will

only operate properly in a single direction, and

the motor is wound so that if the connections are

correct, the rotation will also be correct.

Phase sequence and

reverse rotation protection

Compressor models SH090-105-120-140-161-

184 have no internal reverse rotation protection.

If reverse rotation occurs it will be obvious as

soon as power is turned on. The compressor will

not build-up any pressure, the sound level will be

abnormally high and power consumption will be

minimal. In such case, shut down the compres-

sor immediately and connect the phases to their

proper terminals. Prolonged reverse rotation will

damage the compressor.

Phase sequence detector is strongly

recommended.

9

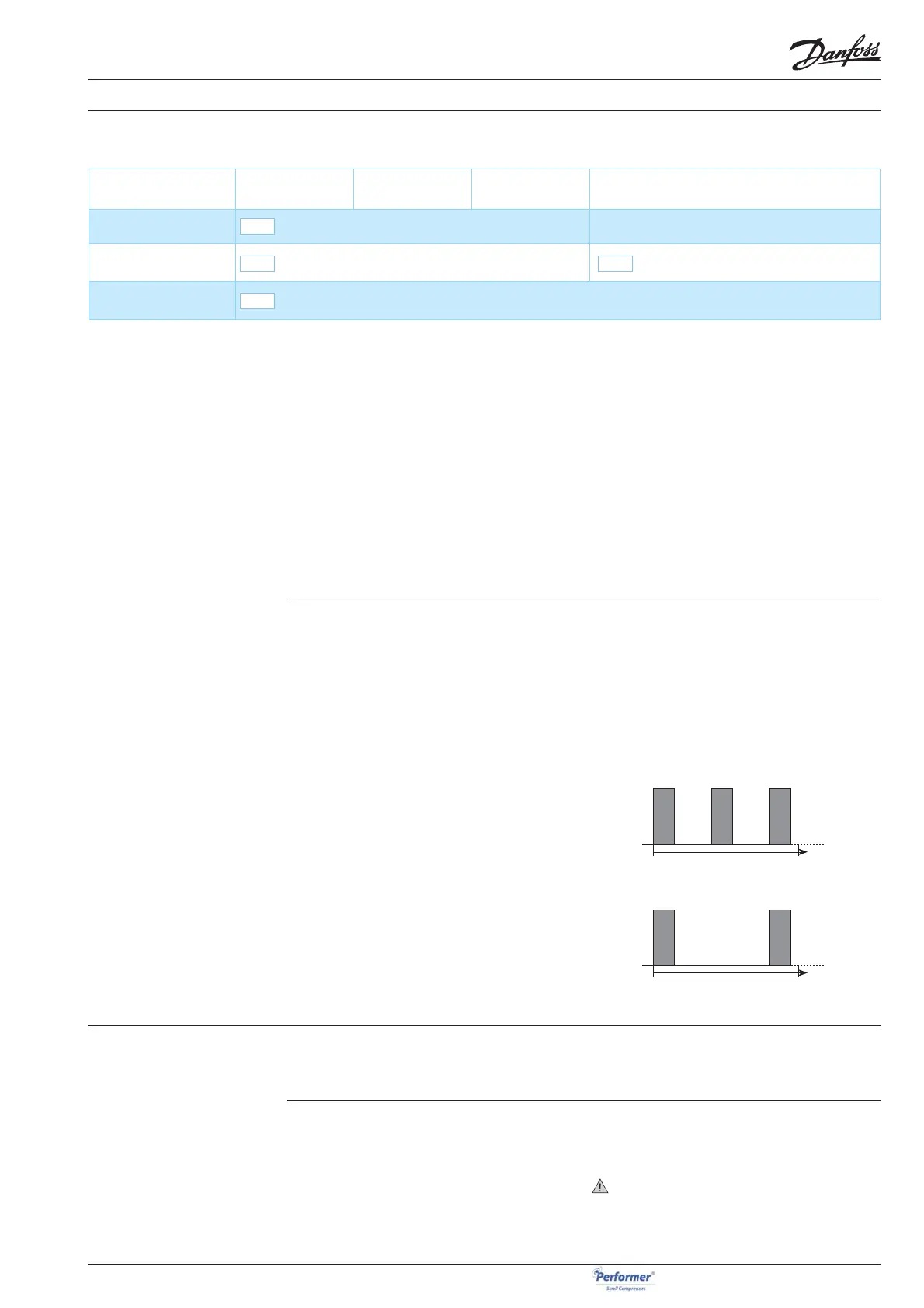

Compressor model

Overheating

protection

Over current

protection

Locked rotor

protection

Phase reversal protection

SH 090 - 105 - 120 - 140-

161 - 184

Internal motor protection Phase sequence detector recommended

SH 180 Electronic module located in terminal box Reverse vent valve

SH240 - 300 - 380 Electronic module located in terminal box

9

9

9

Loading...

Loading...