APPLICATION GUIDELINES

FRCC.PC.007.B5.02

25

OPERATING CONDITIONS

Motor supply SH scroll compressors can be operated at nomi-

nal voltages as indicated section "Motor volt-

age". Under-voltage and over-voltage operation

is allowed within the indicated voltage ranges. In

case of risk of under-voltage operation, special

attention must be paid to current draw.

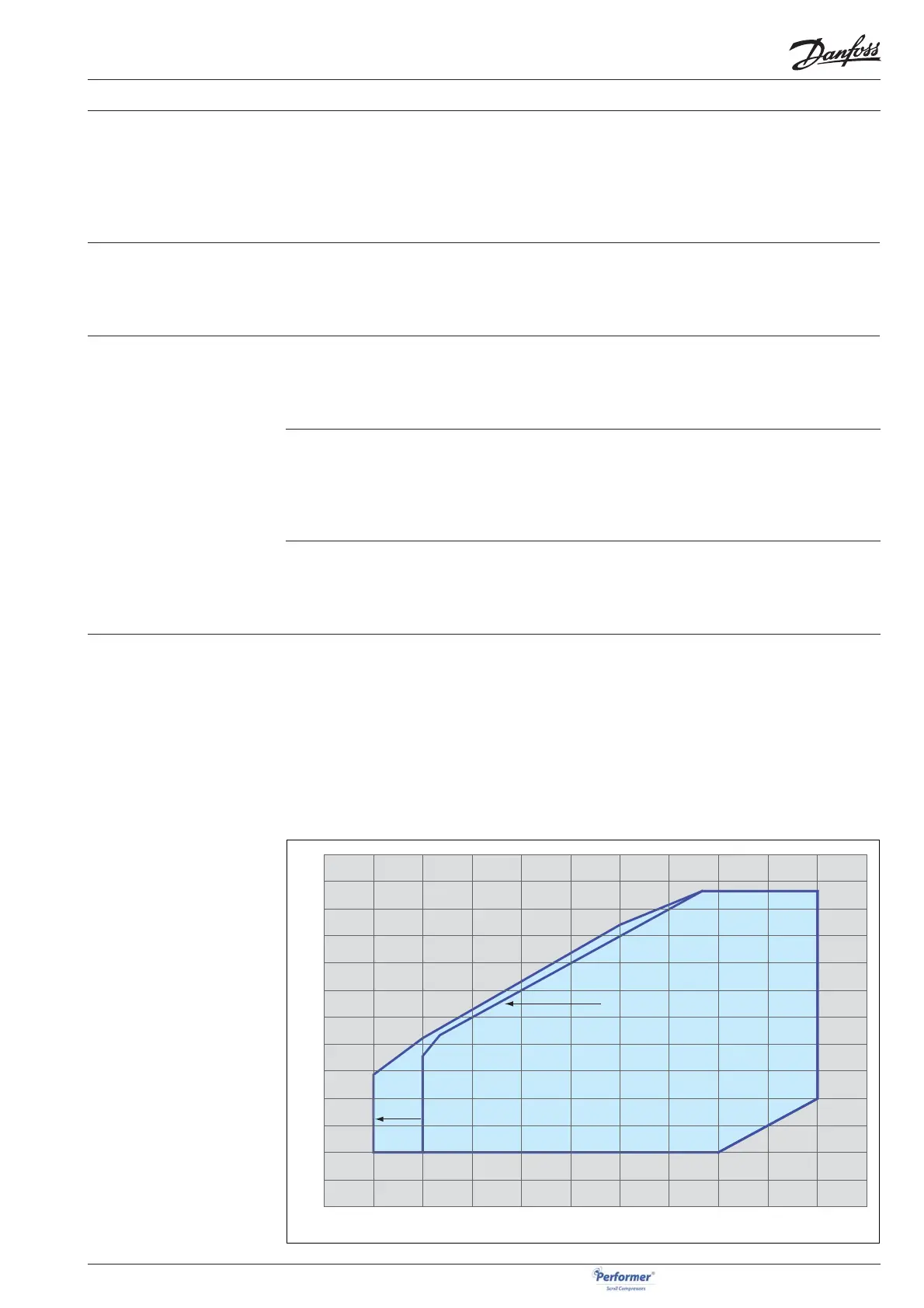

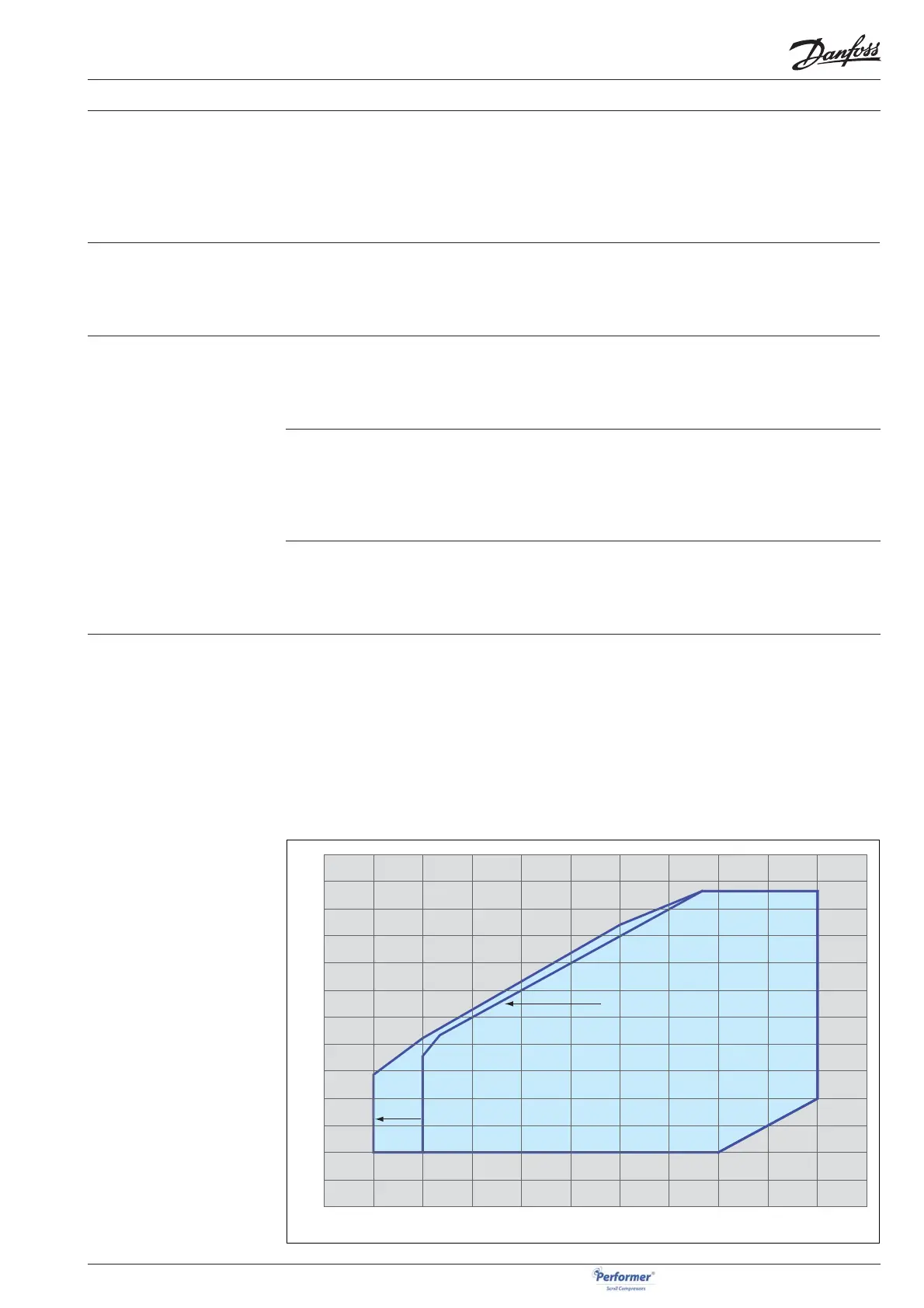

The operating envelope for SH scroll compressors

is given in the fi gure below, where the condens-

ing and evaporating temperatures represent the

range for steady-state operation. Under transient

conditions, such as start-up and defrost, the com-

pressor may operate outside this envelope for

short periods.

The operating limits serve to defi ne the envelope

within which reliable operations of the compres-

sor are guaranteed:

• Maximum discharge gas temperature: +135°C,

• A suction superheat below 5 K is not recom-

mended due to the risk of liquid fl ood back,

• Maximum superheat of 30 K,

• Minimum and maximum evaporating and con-

densing temperatures as per the operating

envelopes.

SH compressors can be applied from -35°C to 55°C

ambient temperature for SH090-105-120-140-161-

184 and 51°C ambient temperature for SH180-

240-300-380. The compressors are designed as

100 % suction gas cooled without need for addi-

tional fan cooling. Ambient temperature has very

little eff ect on the compressor performance.

Application envelope

Compressor ambient

temperature

10

15

20

25

30

35

40

45

50

55

60

65

70

75

-35 -30 -25 -20 -15 -10 -5 0 5 10 15 20

Evaporating temperature (°C)

Condensing temperature (°C)

SH = 11.1 K

SH = 5 K

POE oil Polyolester oil (POE) is miscible with HFC's (while

mineral oil is not), but has to be evaluated regard-

ing lubrication ability in compressors.

POE oil has better thermal stability than refriger-

ant mineral oil.

POE is more hygroscopic and also holds moisture

more tight than mineral oil.

It also chemically reacts with water leading to acid

and alcohol formation.

In case of enclosed fi tting and high ambient tem-

perature it’s recommend to check the tempera-

ture of power wires and conformity to their insu-

lation specifi cation.

In case of safe tripping by the internal compres-

sor overload protection the compressor must

cool down to about 60°C before the overload will

reset. A high ambient temperature can strongly

delay this cool-down process.

Although the compressor itself can withstand low

ambient temperature, the system may require

specifi c design features to ensure safe and reli-

able operation. See section ‘Specifi c application

recommendations’.

High ambient temperature

Low ambient temperature

Loading...

Loading...