APPLICATION GUIDELINES

FRCC.PC.007.B5.02

19

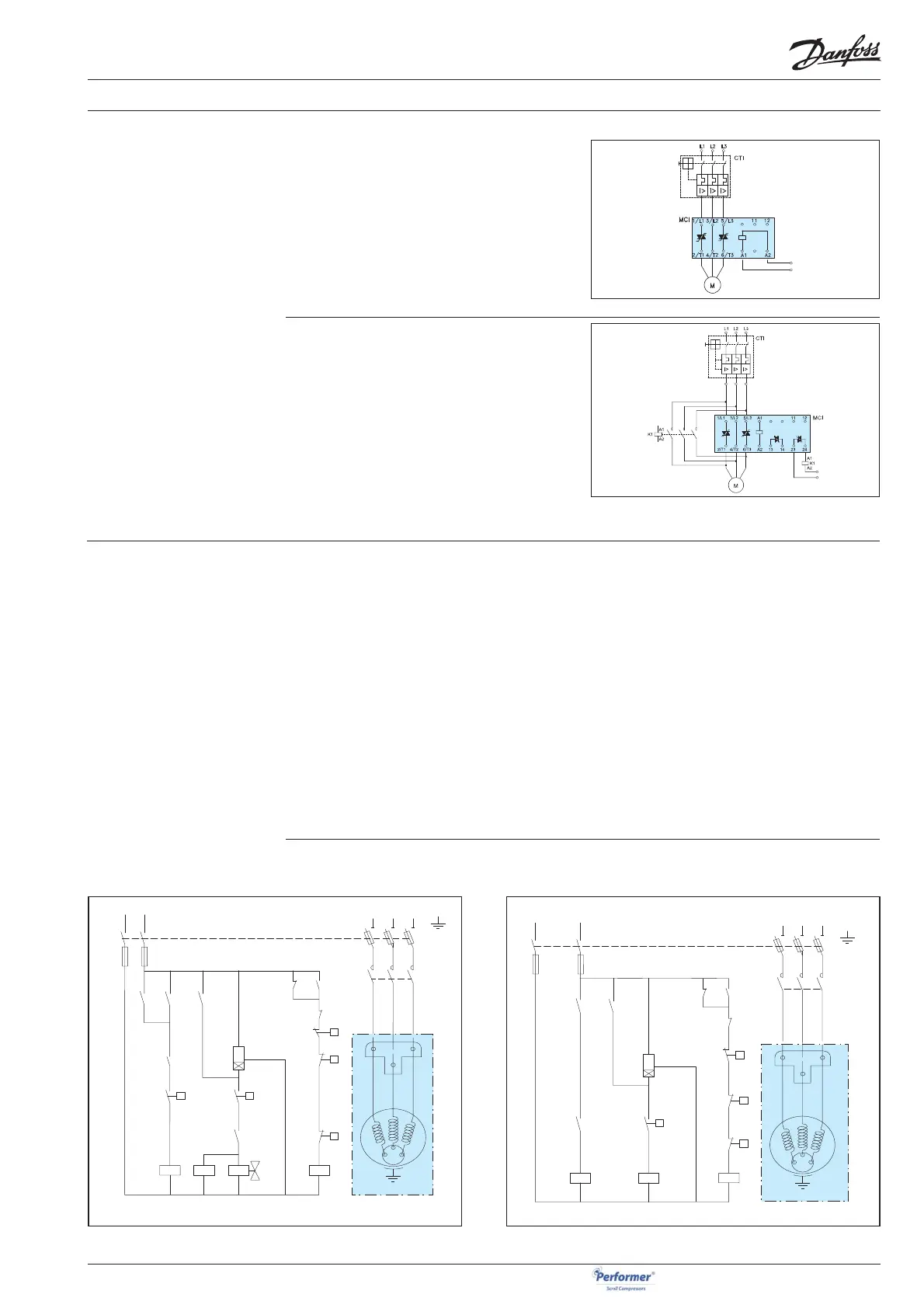

Suggested wiring diagrams logic

Compressor model SH 090 - 105 - 120 - 140 - 161 - 184

ELECTRICAL DATA, CONNECTIONS AND WIRING

By means of the built-in auxiliary contact (23-24)

the by pass function is easily achieved, see wiring

diagram beside.

No heat is generated from the MCI. As the con-

tactor always switches in no-load condition it can

be selected on the basis of the thermal current

(AC-1).

13-14 contact not applicable with MCI 25C.

When the control voltage is applied to A1 - A2,

the MCI soft starter will start the motor, accord-

ing to the settings of the ramp-up time and ini-

tial torque adjustments. When the control volt-

age is switched OFF, the motor will switch off

instantaneously.

MCI with by pass contactor

Input controlled soft start

M

DGT

HP

LPS

180 s

TH

LP

CONTROL CIRCUIT

F1F1

KM

KM

KM

KA KA

A1

A2

A3

KA

KA

KS

KS

KS

L1 L3 L2

Q1

T1

T3

T2

LLSV KS

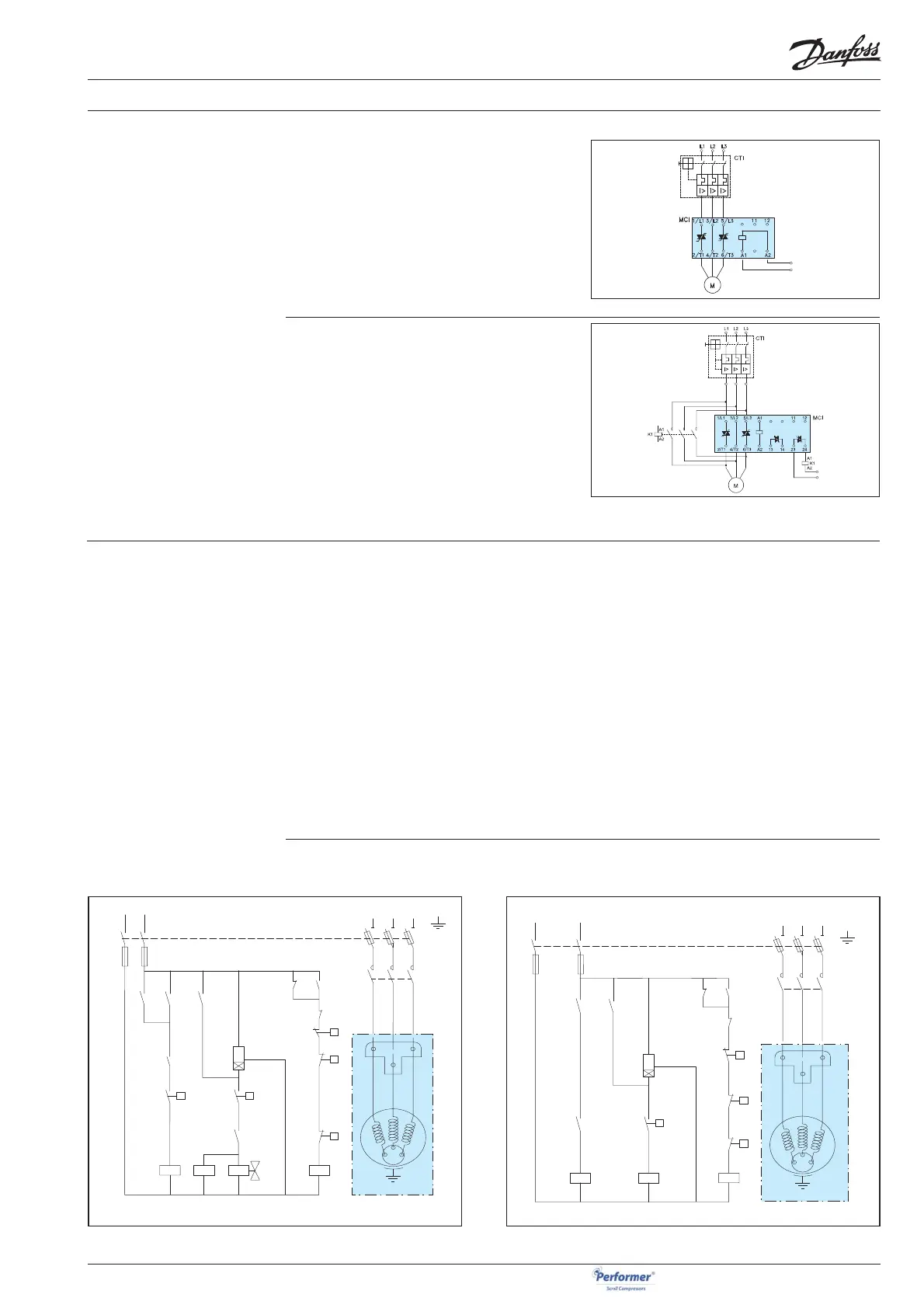

Wiring diagram with pump-down cycle

KM

L1 L3 L2

Q1

CONTROL CIRCUIT

F1F1

KM KA

KA KS

KS

KS

HP

DGT

TH

180 s

85 52 019 - A

T1

T2

M

T3

KA KA

A1

A2

A3

Wiring diagram without pump-down cycle

LPS

General wiring

information

The wiring diagrams below are examples for a

safe and reliable compressor wiring. In case an al-

ternative wiring logic is chosen, it is imperative to

respect the following rules:

When a safety switch trips, the compressor must

stop immediately and must not re-start until the

tripping condition is back to normal and the safe-

ty switch is closed again. This applies to the LP

safety switch, the HP safety switch, the discharge

gas thermostat and the motor safety thermostat.

In specifi c situations, such as winter start opera-

tion, an eventual LP control for pump-down cy-

cles may be temporarily bypassed to allow the

system to build pressure. But it remains manda-

tory for compressor protection to apply an LP

safety switch. The LP safety switch must never be

bypassed.

Pressure settings for the LP and HP safety switch

and pump-down listed in table from section "Low

pressure".

When ever possible (ie. PLC control), it is recom-

mended to limit the possibilities of compressor

auto restart to less than 3 to 5 times during a peri-

od of 12 hours when caused by motor protection

or LP safety switch tripping. This control must be

managed as a manual reset device.

Loading...

Loading...