Page 19 of 108

M-AP-001-EN Rev. N

Functional Description

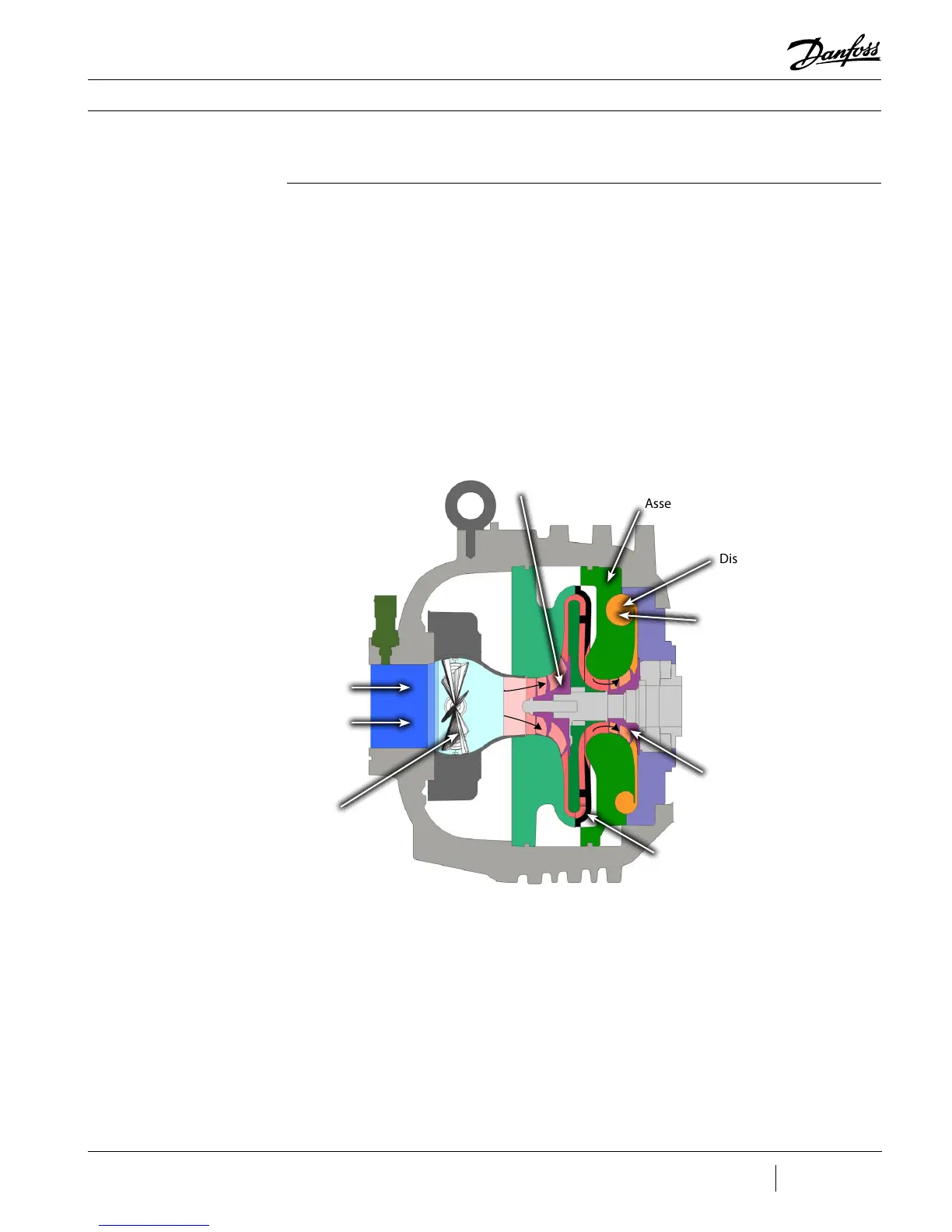

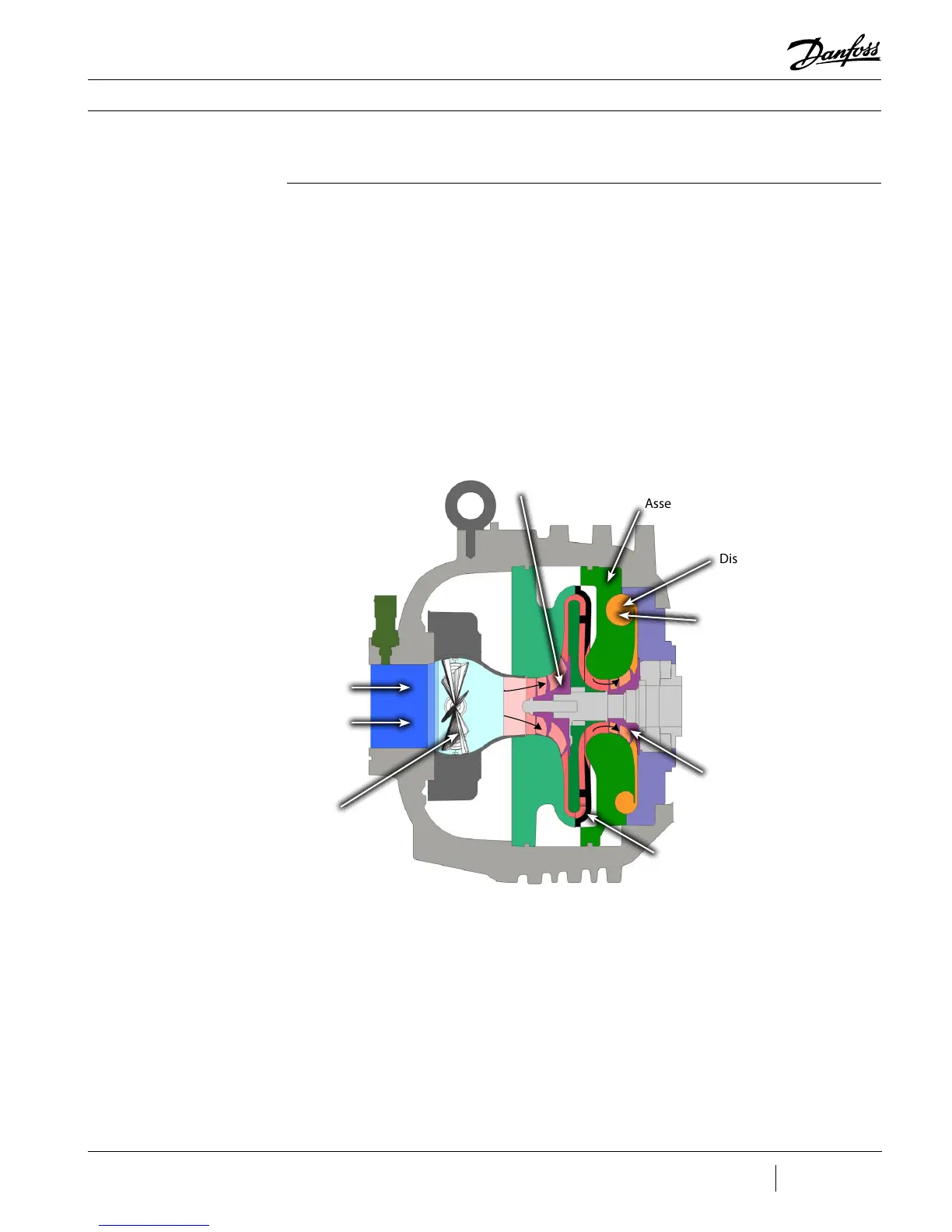

Figure 3-1 - Compressor

Fluid Path TG230 / TT300

3 Functional Description

3.1 Main Fluid Path

Compressor operation begins with a call for cooling from a chiller controller. The compressor

controller then begins compressor ramp-up.

The following paragraphs describe the ow of refrigerant from the intake to the discharge

port of the compressor (see Figure 3-1 and Figure 3-2).

The refrigerant enters the suction side of the compressor as a low-pressure, low-

temperature, super-heated gas. The refrigerant gas passes through a set of adjustable Inlet

Guide Vanes (IGVs) that are used to control the compressor capacity at low-load conditions.

The rst compression element the gas encounters is the rst-stage impeller. The centrifugal

force produced by the rotating impeller results in an increase in both gas velocity and

pressure. The high-velocity gas discharging from the impeller is directed to the second-

stage impeller through de-swirl vanes. The gas is further compressed by the second-stage

impeller and then discharged through a volute via a diuser (a volute is a curved funnel

increasing in area to the discharge port. As the area of the cross-section increases, the volute

reduces the speed of the gas and increases its pressure). From there, the high-pressure/

high-temperature gas exits the compressor at the discharge port.

Discharge Port

Volute

Assembly

1st Stage

Impeller

Low - Pressure / Low -

Temperature Gas

Inlet Guide Vanes

(IGV)

Vaned

Diffuser

2nd Stage Impeller

High - Pressure / High -

Temperature Gas

Loading...

Loading...