Page 29 of 108

M-AP-001-EN Rev. N

Control Interface Wiring

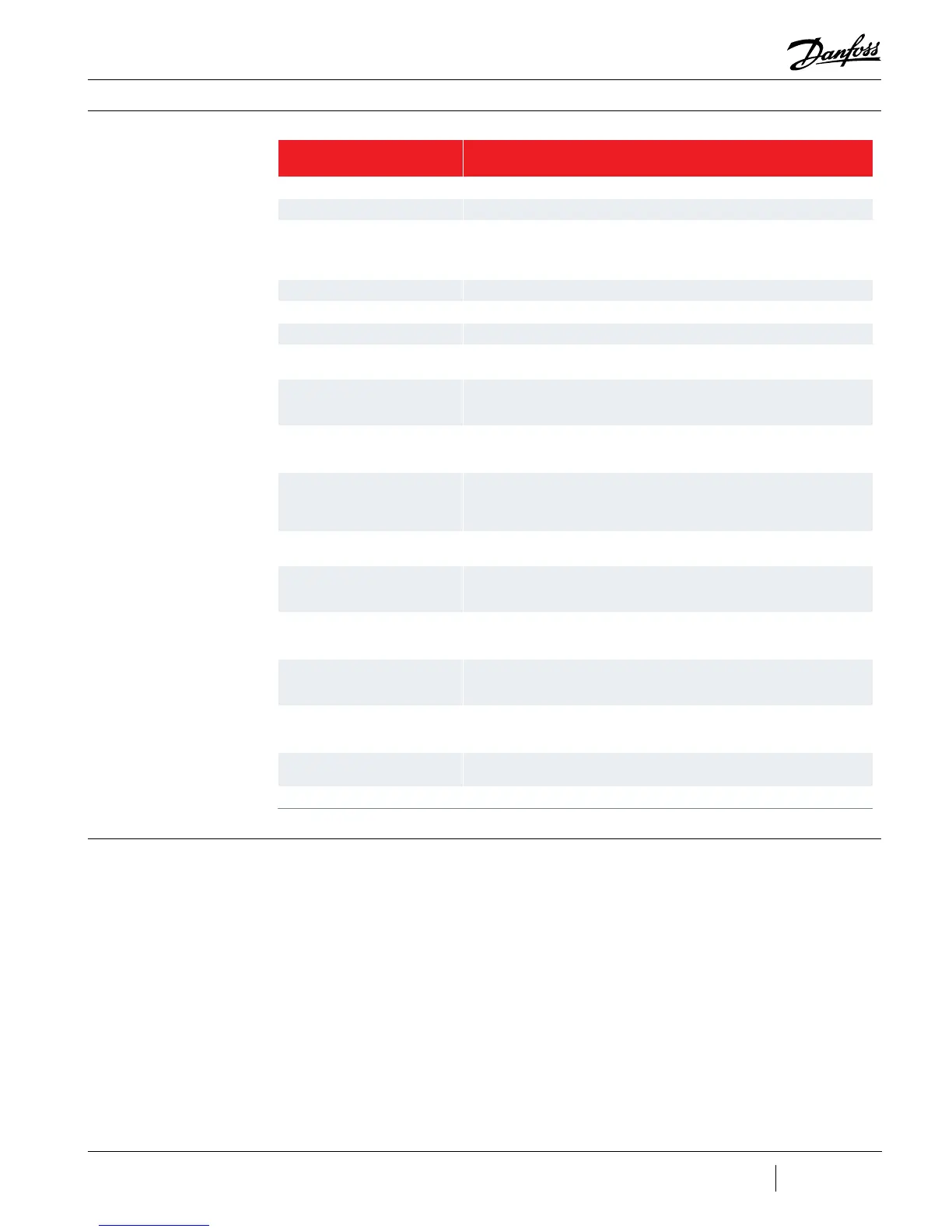

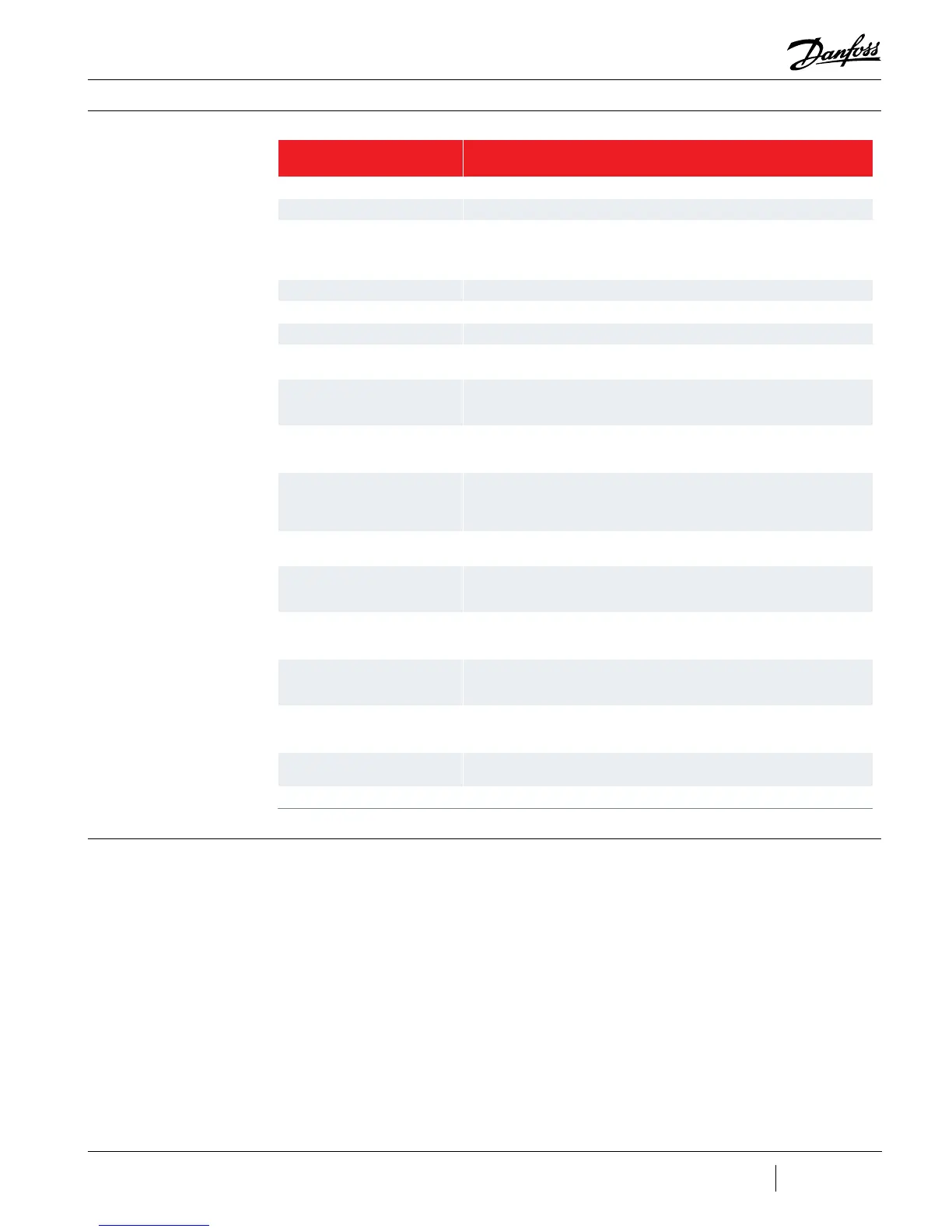

Table 4-1 - Control Wiring

Details

To ensure proper control wiring techniques, follow these guidelines:

1. The ground reference of the external circuit connected to the Compressor I/O Board

must be at the same potential as the ground reference on the Compressor I/O Board.

2. The Interlock circuit should be voltage-free. For instance, all external contractors/

switches must not introduce current into the circuit.

3. Analog outputs (such as Motor Speed) must be received by the external circuit without

sending current back to the Compressor I/O Board.

4. All interlock and analog output cables should be shielded with one end of the shield

connected to the common analog or digital ground bus. The other end of the shield

must not be grounded as this would create a ground loop. Refer to Figure 4-2.

4.1 Control Wiring

Connection Guidelines

I/O Description

COM (shield) Shield for RS-485 communication

Modbus RS-485 NetB/NetA Modbus over RS-485 communication port

Stepper Motor 1 Phase 1A, 1B, 2A,

2B and

Stepper Motor Phase 1A, 1B, 2A,

2B

Optional output connections for controlling the main electronic expansion

valve (evaporator) or auxillary electronic expansion valve (economizer or load

balancing valve). 200ma Maximum output on each driver. Valve frequency

will eect operational characteristics.

Level Sensor +15V (Evaporator) Power supply for level sensor #1

Sensor Signal (Evaporator) Input from a level sensor to control the main expansion valve (evaporator)

Level Sensor +15V (Economizer) Power supply for level sensor #2

Sensor Signal (Economizer)

Input from a level sensor to control the auxiliary expansion valve

(economizer)

Demand 0 - 10V

Analog input from customer-supplied controller to drive the compressor, i.e.,

0 - max. kW input with a deadband of 2VDC for the respective compressor

model. Only available in 3.1.4; removed in 4.x forward.

Interlock

Connects to a set of external normally closed contacts that typically open in

the event of loss of chilled water or air ow. Typically a 1.5VDC Output signal.

NOTE: This is not a safety certied interlock.

Status

An internal normally open contact that is closed during normal operation

and opens in the event of a compressor fault. With the circuit open, the

compressor will not restart until the demand signal has been reset to 0 (via

chiller/unit controller). Circuit rated at 1A @ 30VDC/24VAC or .03A @ 120VAC.

Liquid Temperature

Optional input for monitoring temperature. The temperature sensor must be

an NTC type 10K @ 25°C thermistor.

Run

An internal N/O contact that is closed while the compressor is running.

The speed at which the contact closes is user-congurable via the monitor

program. Circuit rated at 1A @ 30VDC/24VAC or 0.3A @ 120VAC.

Analog

Universal analog output manually controlled as a percentage of total voltage

written through Modbus. This can be congured for 0-5V or 0-10V via on

board jumpers.

Entering Chilled Water Temp

Analog input indicating water temperature. The temperature sensor must

be an NTC type 10K @ 25°C thermistor. Refer to Application Manual for

thermistor specication.

Leaving Chilled Water Temp

Analog input indicating water temperature. The temperature sensor must

be an NTC type 10K @ 25°C thermistor. Refer to Application Manual for

thermistor specication.

Spare T +/-

Optional input for monitoring temperature. The temperature sensor must be

an NTC type 10K @ 25°C thermistor.

Spare P +/- Can be connected to a 0-5V type pressure sensor

Loading...

Loading...