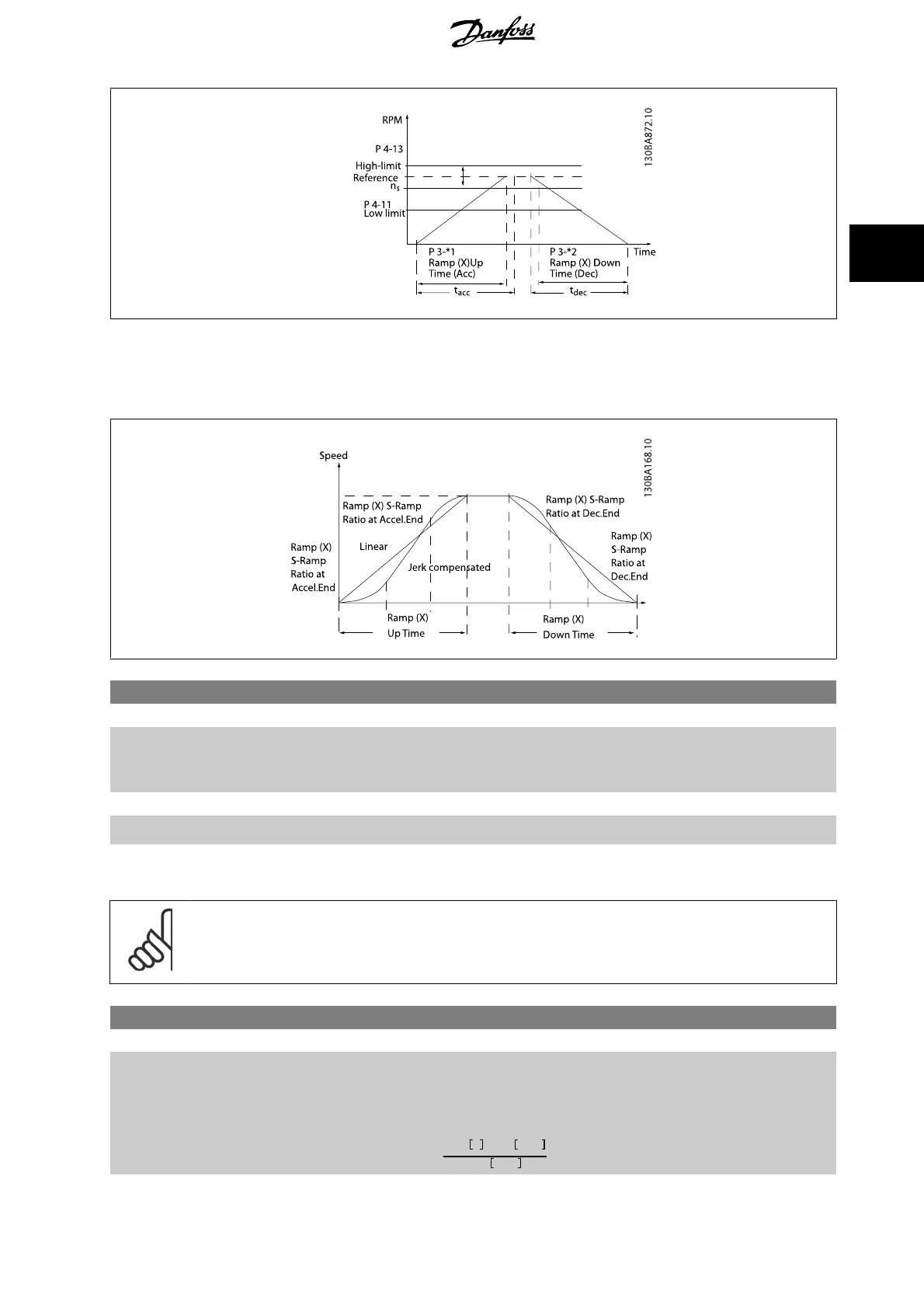

If S-ramps are selected then set the level of non-linear jerk compensation required. Set jerk compensation by defining the proportion of ramp-up and

ramp-down times where acceleration and deceleration are variable (i.e. increasing or decreasing). The S-ramp acceleration and deceleration settings are

defined as a percentage of the actual ramp time.

3-40 Ramp 1 Type

Option: Function:

Select the ramp type, depending on requirements for acceleration/deceleration.

A linear ramp will give constant acceleration during ramping. An S-ramp will give non-linear accel-

eration, compensating for jerk in the application.

[0] * Linear

[1] S-ramp Const Jerk Acceleration with lowest possible jerk.

[2] S-ramp Const Time S-ramp based on the values set in par. 3-41

Ramp 1 Ramp up Time

and par. 3-42

Ramp 1 Ramp

Down Time

.

NB!

If S-ramp [1] is selected and the reference during ramping is changed the ramp time may be prolonged in order to realize a jerk free

movement which may result in a longer start or stop time.

Additional adjustment of the S-ramp ratios or switching initiators may be necessary.

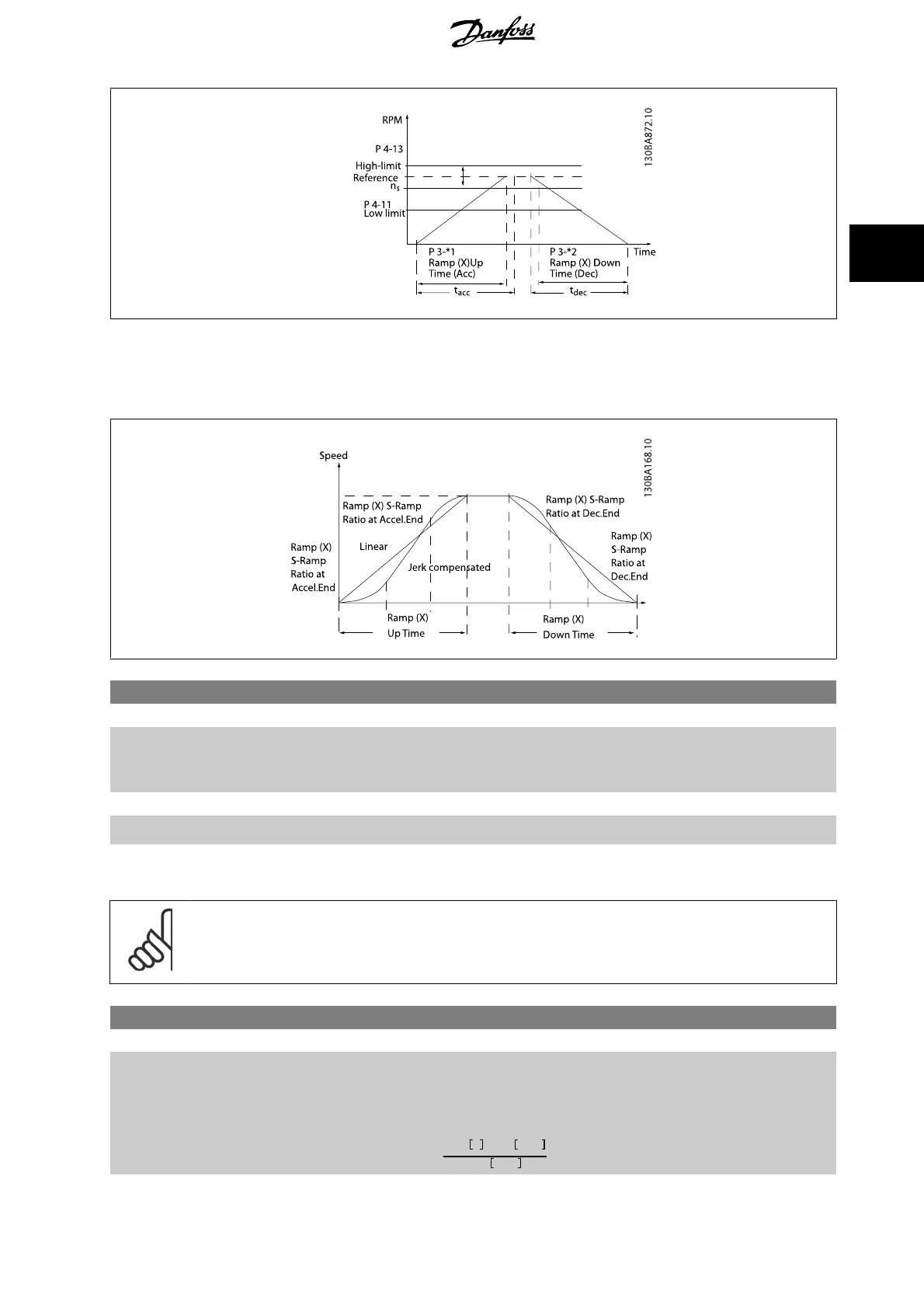

3-41 Ramp 1 Ramp up Time

Range: Function:

Application

dependent*

[Application dependant] Enter the ramp-up time, i.e. the acceleration time from 0 RPM to the synchronous motor speed n

S

.

Choose a ramp-up time such that the output current does not exceed the current limit in

par. 4-18

Current Limit

during ramping. The value 0.00 corresponds to 0.01 sec. in speed mode.

See ramp-down time in par. 3-42

Ramp 1 Ramp Down Time

.

Par

. 3 − 41 =

t

acc

s

x

n

s

RPM

ref

RPM

FC 300 Programming Guide 3 Parameter descriptions

MG.33.M8.02 - VLT

®

is a registered Danfoss trademark

77

3

Loading...

Loading...