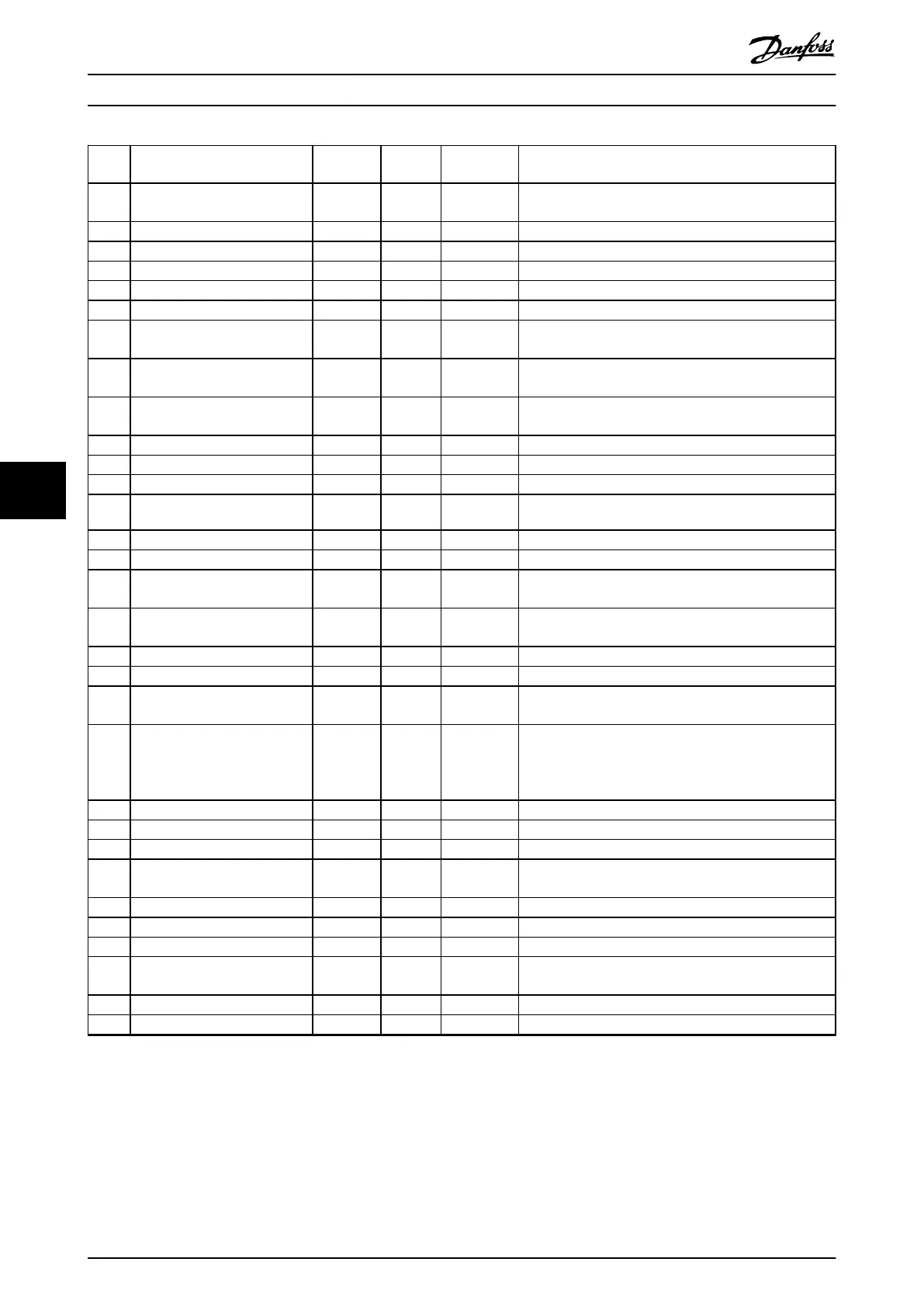

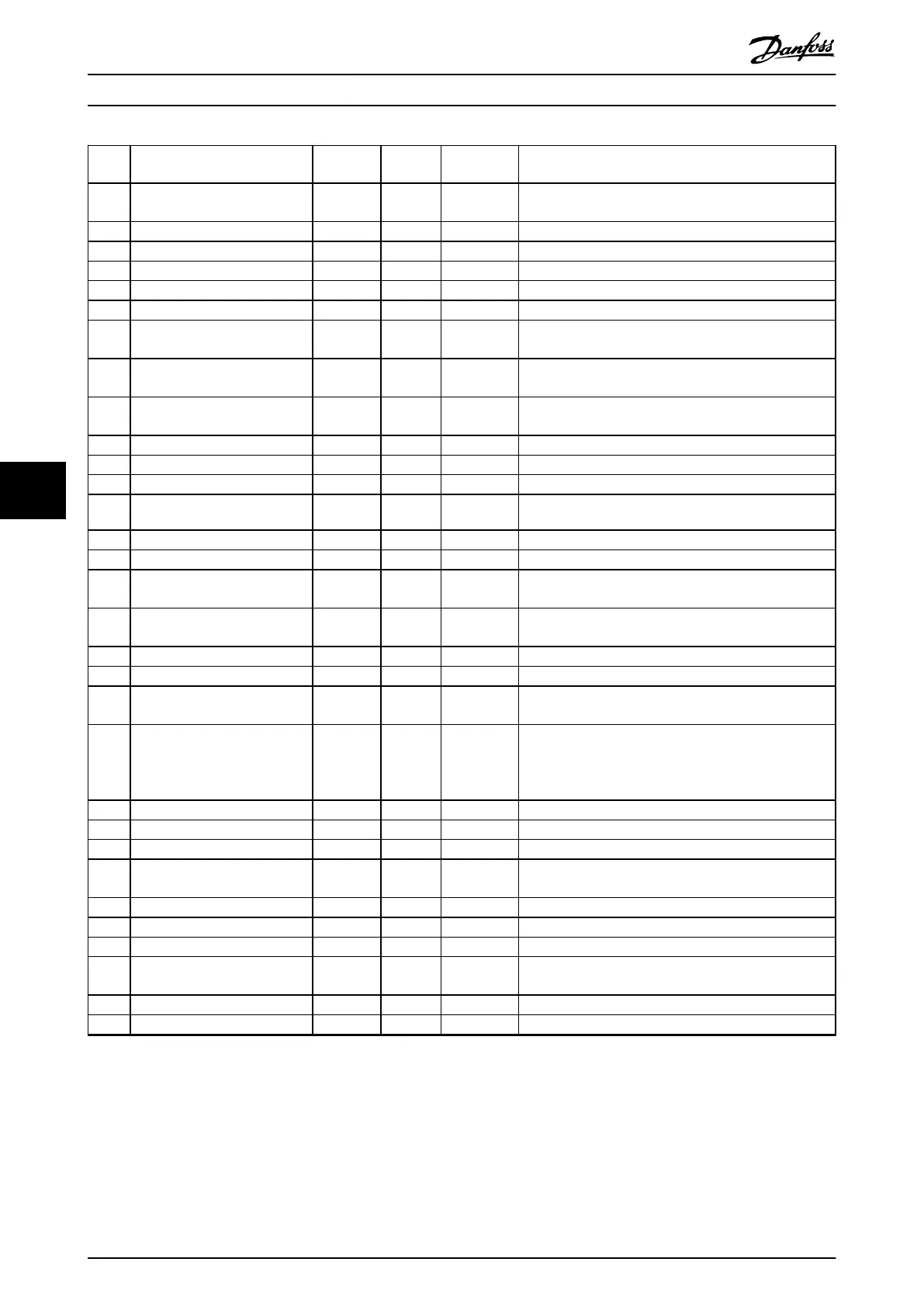

Numb

er

Description Warning Alarm Trip lock Cause

41 Overload T29 X – –

Check the load connected to terminal 29 or remove

short-circuit connection.

46 Gate drive voltage fault – X X –

47 24 V supply low X X X 24 V DC may be overloaded.

50 AMA calibration – X – –

51 AMA check U

nom

and I

nom

– X – Wrong setting for motor voltage and/or motor current.

52 AMA low I

nom

– X – Motor current is too low. Check the settings.

53 AMA big motor – X –

The power size of the motor is too large for the AMA to

operate.

54 AMA small motor – X –

The power size of the motor is too small for the AMA to

operate.

55 AMA parameter range – X –

The parameter values of the motor are outside of the

acceptable range. AMA does not run.

56 AMA interrupt – X – The AMA is interrupted.

57 AMA timeout – X – –

58 AMA internal – X – Contact Danfoss.

59 Current limit X X – Frequency converter overload.

60 External Interlock – X – –

61 Encoder loss X X – –

63 Mechanical brake low – X –

Actual motor current has not exceeded release brake

current within start delay time window.

65 Control card temp X X X

The cutout temperature of the control card is 80 °C

(176 °F).

69 Power card temp X X X –

70 Illegal FC cong – X X –

80

Frequency converter initialized

to default value

– X – All parameter settings are initialized to default settings.

87 Auto DC brake X – –

Occurs in IT mains when the frequency converter coasts

and the DC voltage are higher than 830 V. Energy on DC-

link is consumed by the motor. This function can be

enabled/disabled in parameter 0-07 Auto DC Braking.

90 Feedback monitor X X – A feedback fault is detected by option B.

95 Broken belt X X – –

99 Locked rotor – X – –

101

Flow/pressure information

missing

– X X –

120 Position control fault – X – –

124 Tension limit – X – –

126 Motor rotating – X – –

127

Back EMF too high

2)

X – –

Try to start PM motor which is rotating in an abnormal

high speed.

250 New spare part – X X –

251 New type code – X X –

Table 7.1 Warnings and Alarms Code List

1) These faults may be caused by mains distortions. Installing a Danfoss line

lter may rectify this problem.

2) For enclosure size J7, the warning can also be caused by high UDC voltage.

For diagnosis, read out the alarm words, warning words, and extended status words.

Diagnostics and Troubleshoo...

VLT

®

AutomationDrive FC 360

48 Danfoss A/S © 03/2017 All rights reserved. MG06A702

77

Loading...

Loading...