5.8.5 Conguring RS485 Serial

Communication

RS485 is a 2-wire bus interface compatible with multi-drop

network topology, and it contains the following features:

•

Either Danfoss FC or Modbus RTU communication

protocol, which are internal to the drive, can be

used.

•

Functions can be programmed remotely using

the protocol software and RS485 connection or in

parameter group 8-** Communications and

Options.

•

Selecting a specic communication protocol

changes various default parameter settings to

match the specications of the protocol, making

more protocol-specic parameters available.

•

Option cards for the drive are available to provide

more communication protocols. See the option

card documentation for installation and operation

instructions.

•

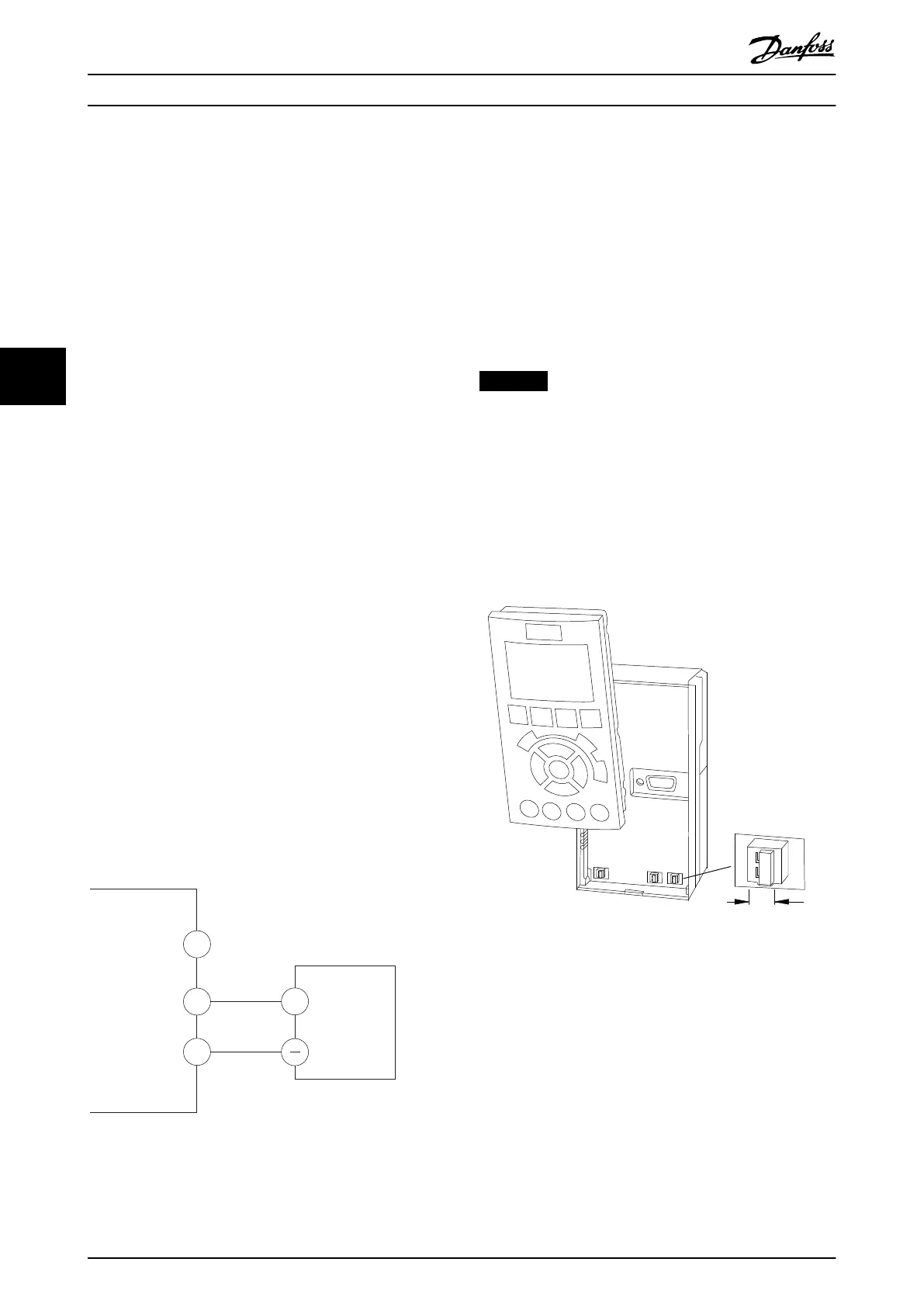

A switch (BUS TER) is provided on the control

card for bus termination resistance. See

Illustration 5.16.

For basic serial communication set-up, perform the

following steps:

1. Connect RS485 serial communication wiring to

terminals (+)68 and (-)69.

1a Use shielded serial communication cable

(recommended).

1b See chapter 5.4 Connecting to Ground for

proper grounding.

2. Select the following parameter settings:

2a Protocol type in parameter 8-30 Protocol.

2b Drive address in parameter 8-31 Address.

2c Baud rate in parameter 8-32 Baud Rate.

Illustration 5.15 Serial Communication Wiring Diagram

5.8.6 Selecting Voltage/Current Input

Signal

The analog input terminals 53 and 54 allow setting of

input signal to voltage (0–10 V) or current (0/4–20 mA).

Default parameter setting:

•

Terminal 53: Speed reference signal in open loop

(see parameter 16-61 Terminal 53 Switch Setting).

•

Terminal 54: Feedback signal in closed loop (see

parameter 16-63 Terminal 54 Switch Setting).

NOTICE

Disconnect power to the drive before changing switch

positions.

1. Remove the LCP (local control panel).

See chapter 3.7 LCP Menus.

2. Remove any optional equipment covering the

switches.

3. Set switches A53 and A54 to select the signal

type (U = voltage, I = current).

BUS TER.

OFF-ON

A53 A54

U- I U- I

Illustration 5.16 Location of Terminal 53 and 54 Switches

Electrical Installation VLT® AutomationDrive FC 361

34 Danfoss A/S © 06/2018 All rights reserved. MG06I102

55

Loading...

Loading...