3.4.2 Extra Protection (RCD)

ELCB relays, multiple protective grounding, or standard

grounding provide extra protection, if local safety

regulations are followed.

In the case of a ground fault, a DC component develops in

the fault current.

If using ELCB relays, observe local regulations. Relays must

be suitable for protection of 3-phase equipment with a

bridge rectifier and for a brief discharge on power-up.

3.4.3

RFI Switch

Mains supply isolated from ground

If the frequency converter is supplied from an isolated

mains source or TT/TN-S mains with grounded leg, turn off

the RFI switch via 14-50 RFI Filter on both frequency

converter and the filter. For further reference, see IEC

364-3. When optimum EMC performance is needed,

parallel motors are connected, or the motor cable length is

above 25 m, set 14-50 RFI Filter to [ON].

In OFF, the internal RFI capacitors (filter capacitors)

between the chassis and the intermediate circuit are cut

off to avoid damage to the intermediate circuit and reduce

ground capacity currents (IEC 61800-3).

Refer to the application note VLT on IT mains. It is

important to use isolation monitors that work together

with power electronics (IEC 61557-8).

3.4.4

Shielded Cables

It is important to connect shielded cables properly to

ensure high EMC immunity and low emissions.

Connection can be made using either cable glands or

clamps:

•

EMC cable glands: Generally available cable

glands can be used to ensure an optimum EMC

connection.

•

EMC cable clamp: Clamps allowing easy

connection are supplied with the unit.

3.4.5

Motor Cable

Connect the motor to terminals U/T1/96, V/T2/97, W/T3/98,

on the far right of the unit. Ground to terminal 99. All

types of 3-phase asynchronous standard motors can be

used with a frequency converter. The factory setting is for

clockwise rotation with the frequency converter output

connected as follows:

Terminal No. Function

96, 97, 98

99

Mains U/T1, V/T2, W/T3

Ground

Table 3.4 Terminal Functions

•

Terminal U/T1/96 connected to U-phase

•

Terminal V/T2/97 connected to V-phase

•

Terminal W/T3/98 connected to W-phase

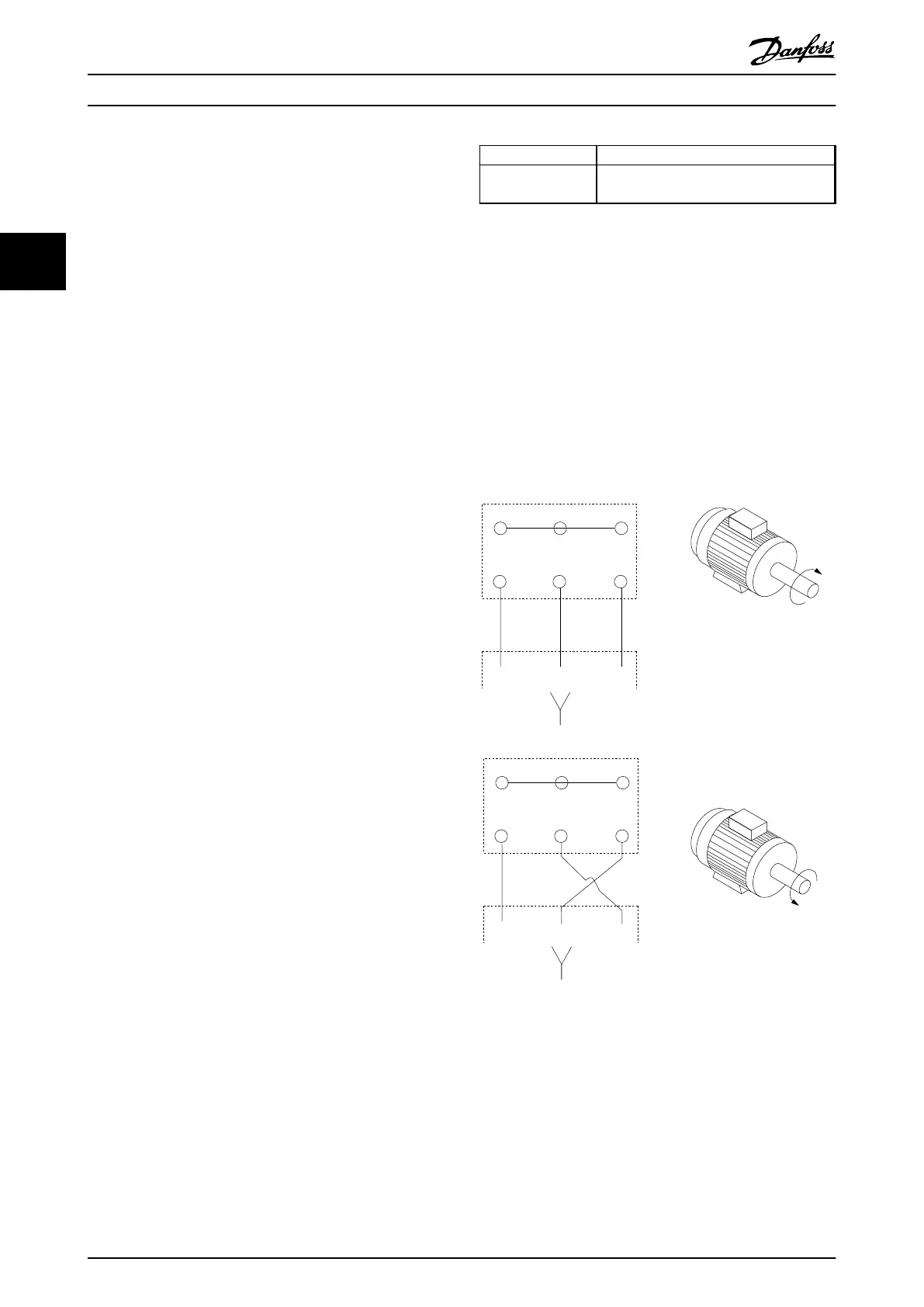

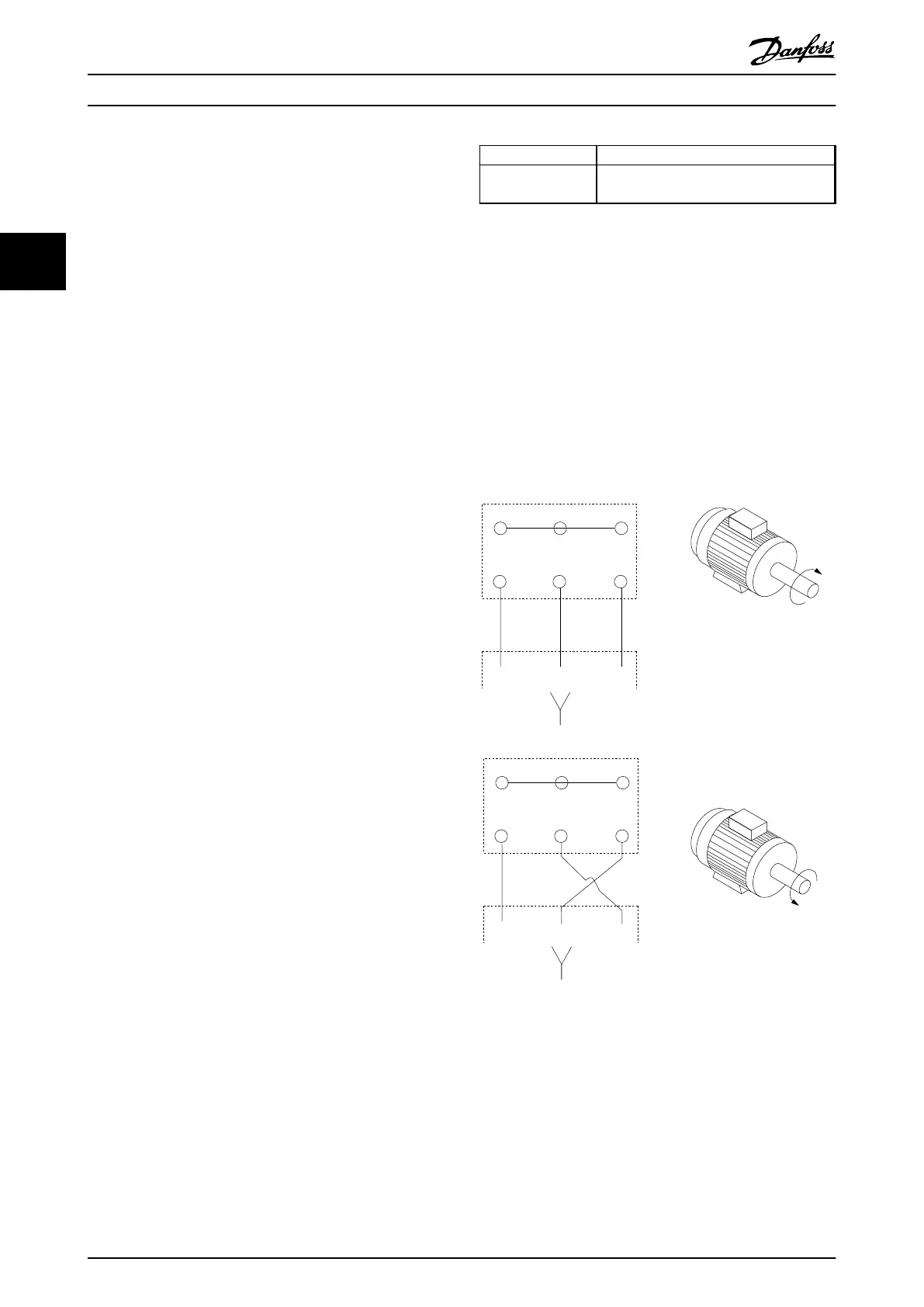

The direction of rotation can be changed by switching 2

phases in the motor cable or by changing the setting of

4-10 Motor Speed Direction.

Motor rotation check can be performed via 1-28 Motor

Rotation Check and following the steps shown in the

display.

175HA036.11

U

1

V

1

W

1

96 97 98

FC

Motor

U

2

V

2

W

2

U

1

V

1

W

1

96 97 98

FC

Motor

U

2

V

2

W

2

Illustration 3.18 Motor Rotation Check

F-frame requirements

Use motor phase cables in quantities of 2, resulting in 2, 4,

6, or 8 to obtain an equal number of wires on both

inverter module terminals. The cables are required to be

equal length within 10% between the inverter module

terminals and the first common point of a phase. The

recommended common point is the motor terminals.

Installation

Operating Instructions

26 Danfoss A/S © Rev. 2014-07-29 All rights reserved. MG37A202

33

Loading...

Loading...