If found to be necessary and after consultation with

Danfoss:

•

Lower the IGBT switching frequency

•

Modify the inverter waveform, 60° AVM vs.

SFAVM

•

Install a shaft grounding system or use an

isolating coupling between motor and load

•

Use minimum speed settings if possible

•

Use a dU/dt or sine-wave filter

3.4.16 Motor Thermal Protection

The electronic thermal relay in the frequency converter has

received UL-approval for single motor protection, when

parameter 1-90 Motor Thermal Protection is set for ETR Trip

and 1-24 Motor Current is set to the rated motor current

(see the motor name plate).

For thermal motor protection, it is also possible to use the

MCB 112 PTC Thermistor Card option. This card provides

ATEX certificate to protect motors in explosion hazardous

areas, Zone 1/21 and Zone 2/22. When

parameter 1-90 Motor Thermal Protection, set to [20] ATEX

ETR, is combined with the use of MCB 112, it is possible to

control an Ex-e motor in explosion hazardous areas.

Consult the Programming Guide for details on how to set

up the frequency converter for safe operation of Ex-e

motors.

To run STO, additional wiring for the frequency converter

is required. Refer to VLT

®

Frequency Converters Safe Torque

Off Operating Instructions for further information.

3.4.17

Control Cable Routing

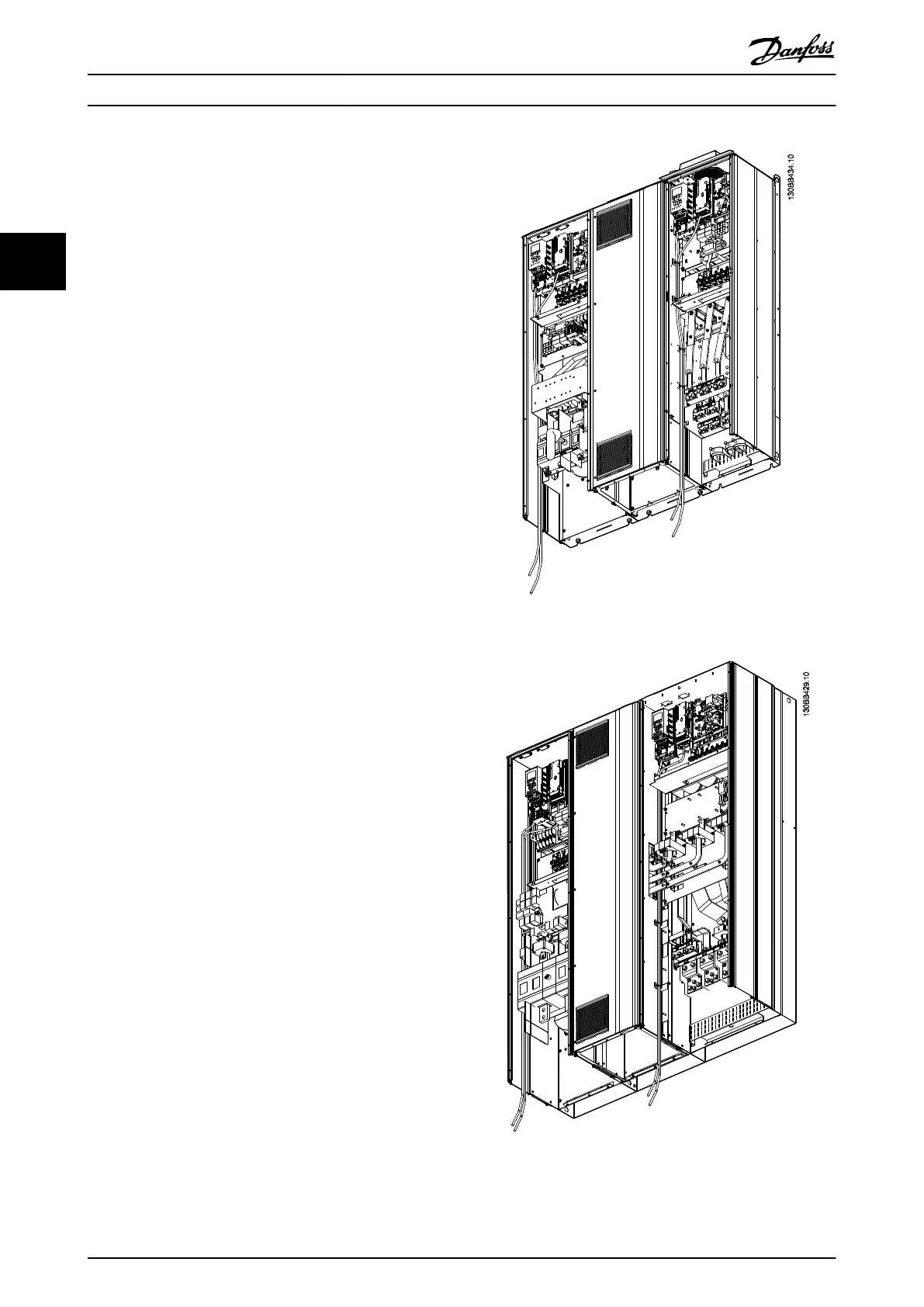

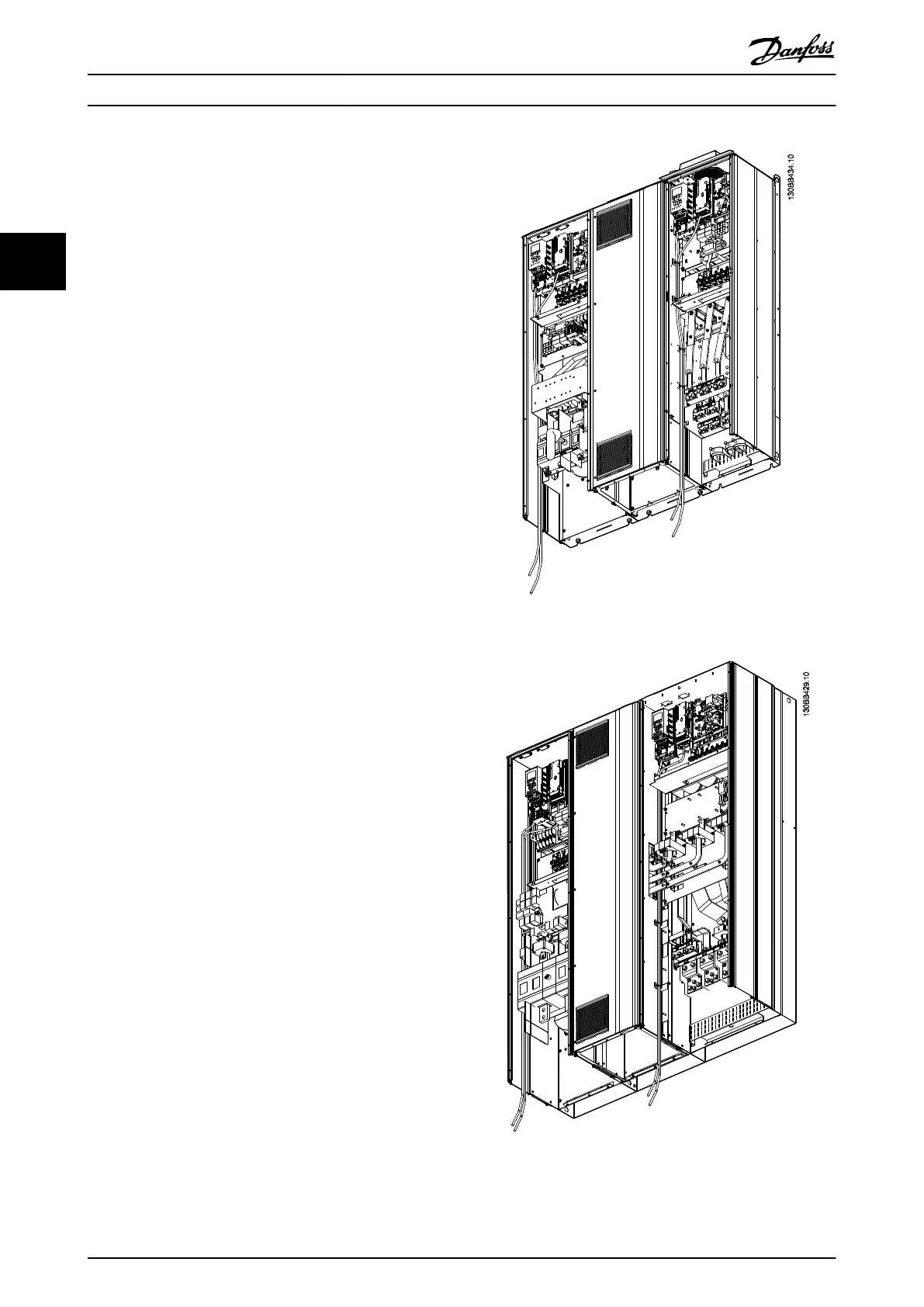

Tie down all control wires to the designated control cable

routing as shown in Illustration 3.21, Illustration 3.22, and

Illustration 3.23. Remember to connect the shields in a

proper way to ensure optimum electrical immunity.

Fieldbus connection

Connections are made to the relevant options on the

control card. For details, see the relevant fieldbus

instruction. The cable must be placed in the provided path

inside the frequency converter and tied down together

with other control wires (see Illustration 3.21 and

Illustration 3.22).

Illustration 3.21 Control Card Wiring Path for Frame Size D13

Illustration 3.22 Control Card Wiring Path for Frame Size E9

Installation Operating Instructions

30 Danfoss A/S © Rev. 2014-07-29 All rights reserved. MG37A202

33

Loading...

Loading...