3.3.6 Torque

Correct torque is imperative for all electrical connections.

The correct torque values are listed in Table 3.2. Incorrect

torque results in a bad electrical connection. Use a torque

wrench to ensure correct torque.

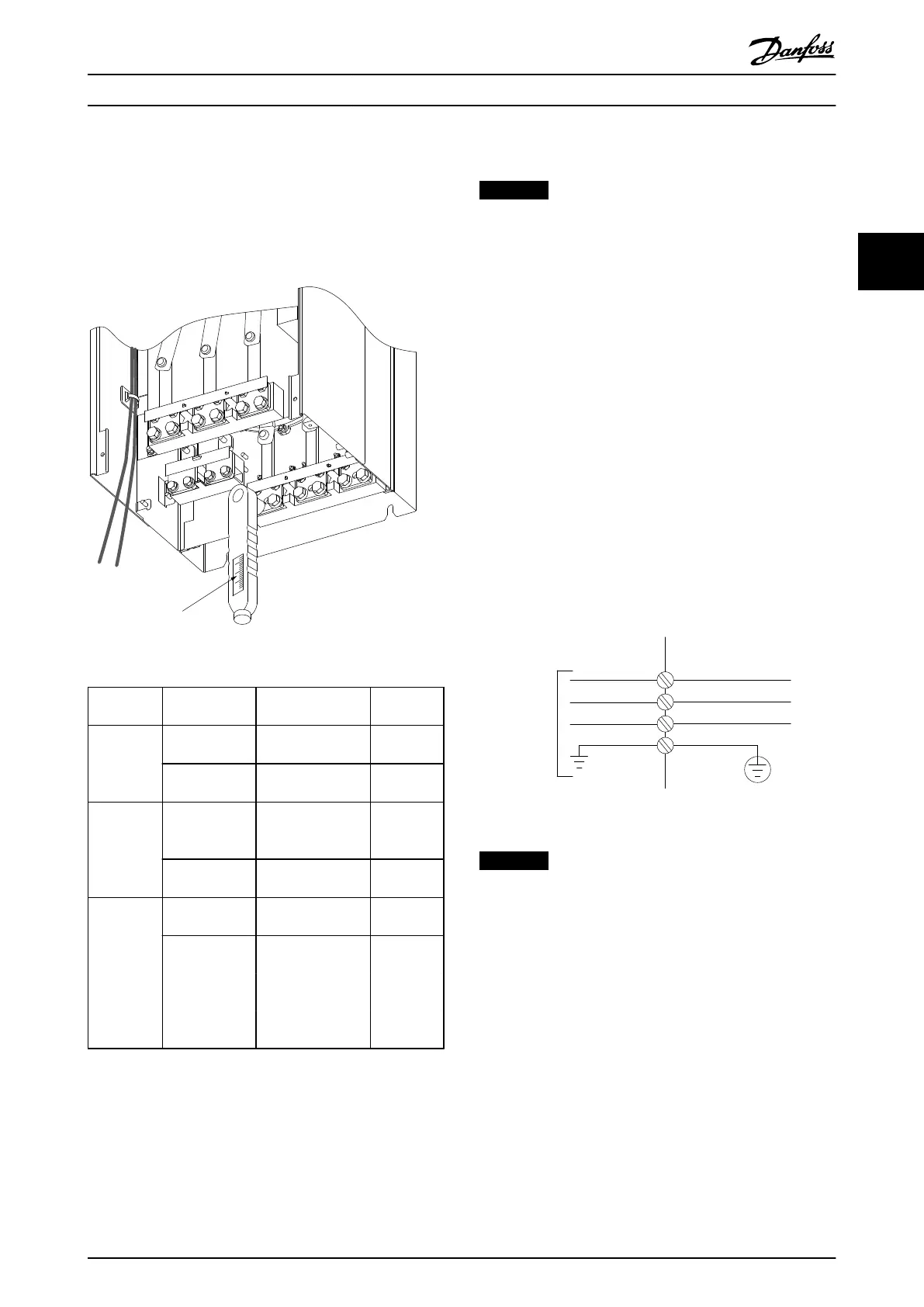

176FA247.12

Nm/in-lbs

-DC 88

+DC 89

R/L1 91

S/L2 92

T/L3 93

U/T1 96

V/T2 97

W/T3

Illustration 3.14 Use a Torque Wrench to Tighten the Bolts

Frame size Terminal Torque [Nm] (in-

lbs)

Bolt size

D

Mains

Motor

19–40

(168–354)

M10

Load sharing

Brake

8.5–20.5

(75–181)

M8

E

Mains

Motor

Load sharing

19–40

(168–354)

M10

Brake

8.5–20.5

(75–181)

M8

F

Mains

Motor

19–40

(168–354)

M10

Load sharing

19–40

(168–354)

M10

Brake

8.5–20.5

(75–181)

M8

Regen

8.5–20.5

(75–181)

M8

Table 3.2 Torque for Terminals

3.4

Electrical Installation

NOTICE

Cables–General Information

All cabling must comply with national and local

regulations on cable cross-sections and ambient

temperature. UL applications require 75 °C copper

conductors. For non-UL applications, 75 and 90 °C

copper conductors are thermally acceptable.

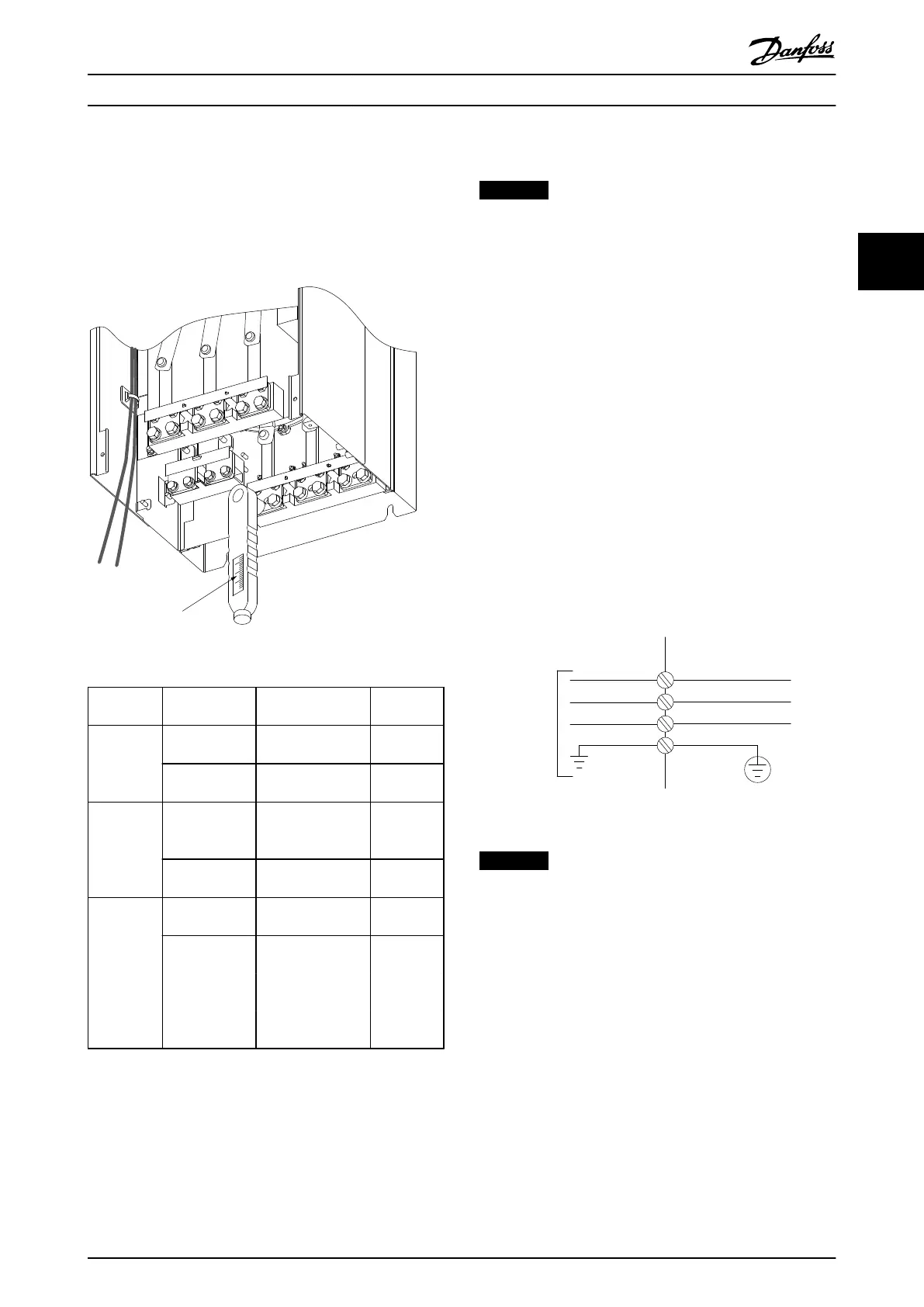

The power cable connections are situated as shown in

Illustration 3.15. Dimension cable cross-section in

accordance with the current ratings and local legislation.

See chapter 11.3.1 Cable lengths and cross-sections for

details.

For protection of the frequency converter, use the

recommended fuses if there are no built-in fuses. Fuse

recommendations are provided in chapter 11.5 Fuses.

Ensure that proper fusing is made according to local

regulation.

The mains connection is fitted to the mains switch, if

included.

3 Phase

power

input

130BA026.10

91 (L1)

92 (L2)

93 (L3)

95 PE

Illustration 3.15 Power Cable Connections

NOTICE

To comply with EMC emission specifications, screened/

armoured cables are recommended. If an unscreened/

unarmoured cable is used, see chapter 3.4.10 Power and

Control Wiring for Unscreened Cables.

See chapter 11 Specifications for correct dimensioning of

motor cable cross-section and length.

Screening of cables

Avoid installation with twisted screen ends (pigtails). They

spoil the screening effect at higher frequencies. If breaking

the screen is necessary to install a motor isolator or

contactor, continue the screen at the lowest possible HF

impedance.

Connect the motor cable screen to both the de-coupling

plate of the frequency converter and to the metal housing

of the motor.

Installation

Operating Instructions

MG37A202 Danfoss A/S © Rev. 2014-07-29 All rights reserved. 23

3 3

Loading...

Loading...