Output junction box requirements

The length, minimum 2.5 m, and quantity of cables must

be equal from each inverter module to the common

terminal in the junction box.

NOTICE

If a retrofit application requires an unequal number of

wires per phase, consult the factory or use the top/

bottom entry side cabinet option, instruction 177R0097.

3.4.6 Brake Cable

Frequency converters with factory installed brake chopper

option

(Only standard with letter B in position 18 of type code).

The connection cable to the brake resistor must be

screened and the max. length from frequency converter to

the DC bar is limited to 25 m.

Terminal No. Function

81, 82 Brake resistor terminals

Table 3.5 Terminal Functions

The connection cable to the brake resistor must be

screened. Connect the screen with cable clamps to the

conductive back plate of the frequency converter and the

metal cabinet of the brake resistor.

Size the brake cable cross-section to match the brake

torque.

WARNING

Note that voltages up to 790 V DC, depending on the

supply voltage, are possible on the terminals.

F-frame requirements

The brake resistors must be connected to the brake

terminals in each inverter module.

3.4.7

Brake Resistor Temperature Switch

The input for the brake resistor temperature switch can be

used to monitor the temperature of an externally

connected brake resistor. If the connection between 104

and 106 is removed, the frequency converter trips on

warning/alarm 27, Brake IGBT.

Install a Klixon switch that is 'normally closed' in series

with the existing connection on either 106 or 104. Any

connection to this terminal must be double insulated

against high voltage to maintain PELV.

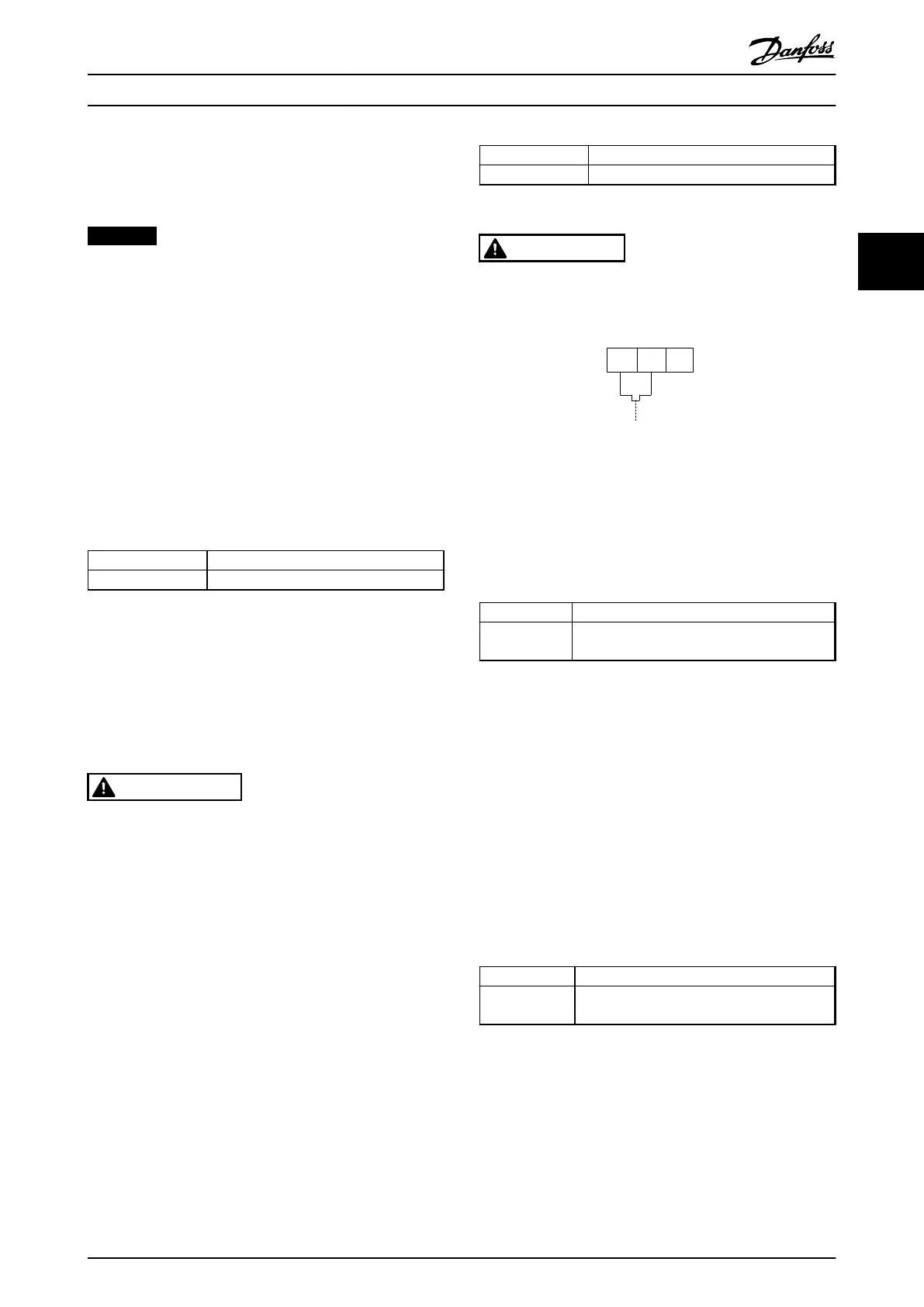

Normally closed: 104–106 (factory installed jumper).

Terminal No. Function

106, 104, 105 Brake resistor temperature switch.

Table 3.6 Terminal Functions

CAUTION

If the temperature of the brake resistor is too high and

the thermal switch drops out, the frequency converter

stops braking. The motor coasts.

175ZA877.10

106

NC

104

C

105

NO

Illustration 3.19 Factory-installed Jumper

3.4.8 Mains Connection

Mains must be connected to terminals 91, 92 and 93 on

the far left of the unit. Ground is connected to the

terminal on the right of terminal 93.

Terminal No. Function

91, 92, 93

94

Mains R/L1, S/L2, T/L3

Ground

Table 3.7 Terminal Functions

Ensure that the power supply can supply the necessary

current to the frequency converter.

If the unit is without built-in fuses, ensure that the

appropriate fuses have the correct current rating.

3.4.9

External Fan Supply

If the frequency converter is supplied by DC or the fan

must run independently of the power supply, use an

external power supply. Make the connection on the power

card.

Terminal No. Function

100, 101

102, 103

Auxiliary supply S, T

Internal supply S, T

Table 3.8 Terminal Functions

The connector on the power card provides the connection

of line voltage for the cooling fans. The fans are connected

from the factory to be supplied from a common AC line

(jumpers between 100–102 and 101–103). If external

power supply is needed, remove the jumpers and connect

the supply to terminals 100 and 101. Protect with a 5 A

fuse. In UL applications, use a LittelFuse KLK-5 or

equivalent.

Installation

Operating Instructions

MG37A202 Danfoss A/S © Rev. 2014-07-29 All rights reserved. 27

3 3

Loading...

Loading...