6.1.3 2-2* Mechanical Brake

Controlling operation of an electro-magnetic (mechanical) brake, typically required in hoisting applications requires special

parameters.

To control a mechanical brake, a relay output (relay 01 or relay 02) or a programmed digital output (terminal 27 or 29) is

required. Normally, this output must be closed during periods when the frequency converter is unable to ‘hold’ the motor,

due to an excessive load. Select [32] Mechanical Brake Control for applications with an electro-magnetic brake in

parameter 5-40 Function Relay, 5-30 Terminal 27 Digital Output, or 5-31 Terminal 29 Digital Output. When selecting [32]

Mechanical brake control, the mechanical brake is closed from startup until the output current is above the level selected in

parameter 2-20 Release Brake Current. During stop, the mechanical brake activates when the speed falls below the level

specified in parameter 2-21 Activate Brake Speed [RPM]. If the frequency converter enters an alarm condition or an over-

current or overvoltage situation, the mechanical brake immediately cuts in, as in the Safe Torque Off function.

NOTICE

Protection mode and trip delay features (14-25 Trip Delay at Torque Limit and 14-26 Trip Delay at Inverter Fault) can

delay the activation of the mechanical brake in an alarm condition. Disable these features in hoisting applications.

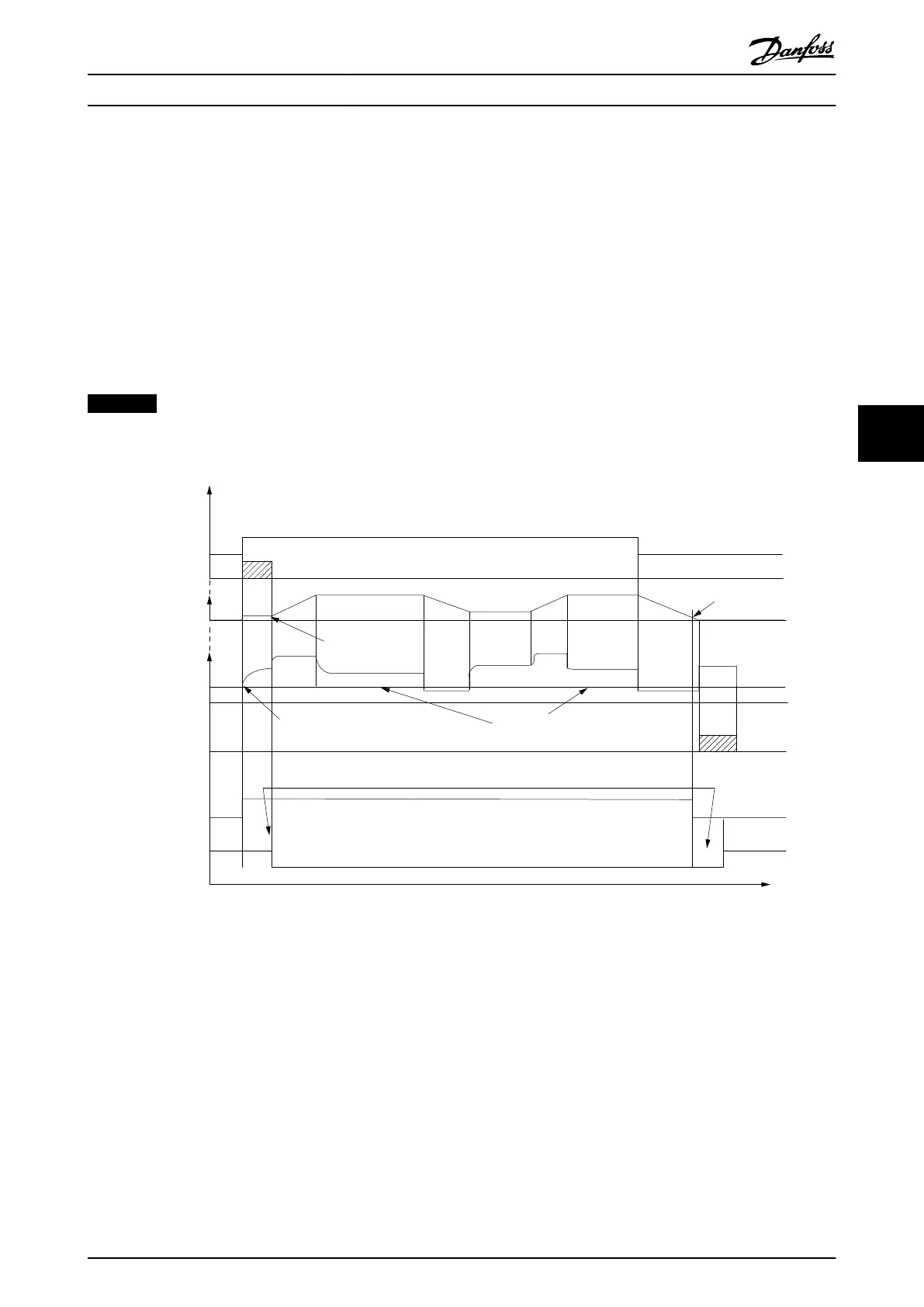

Start

term.18

1=on

0=o

Shaft speed

Start delay time

on

o

Brake delay time

Time

Output current

Relay 01

Pre-magnetizing

current or

DC hold current

Reaction time EMK brake

Par 2-20

Release brake current

Par 1-76 Start current/

Par 2-00 DC hold current

Par 1-74

Start speed

Par 2-21

Activate brake

speed

Mechanical brake

locked

Mechanical brake

free

Par 1-71

Par 2-23

130BA074.12

Illustration 6.7 Mechanical Brake Function

Programming Operating Instructions

MG37A202 Danfoss A/S © Rev. 2014-07-29 All rights reserved. 57

6 6

Loading...

Loading...