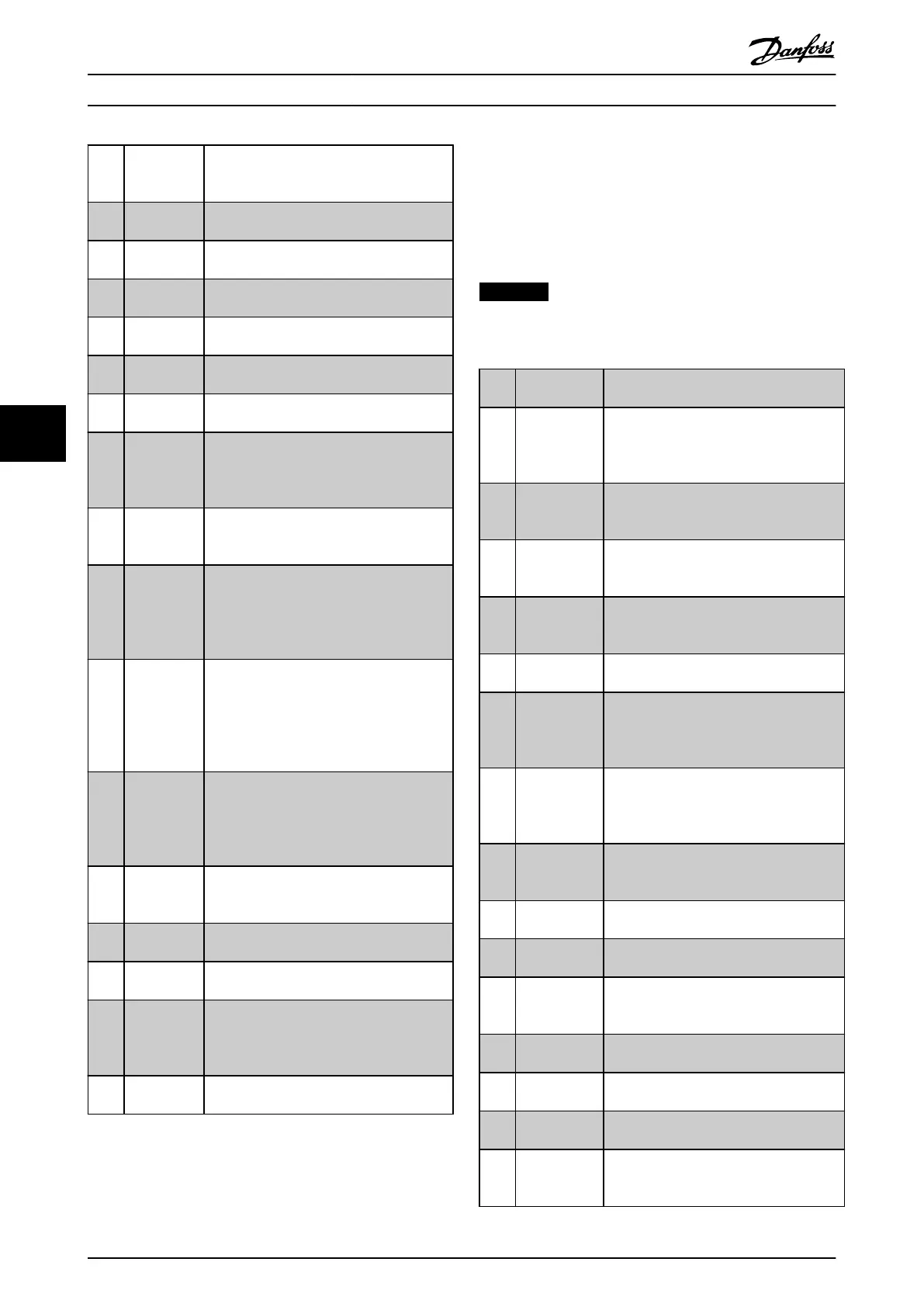

[57] DigiPot Clear Clears the digital potentiometer reference

described in parameter group 3-9* Digital

Pot.Meter

[60] Counter A (Terminal 29 or 33 only) Input for increment

counting in the SLC counter.

[61] Counter A (Terminal 29 or 33 only) input for

decrement counting in the SLC counter.

[62] Reset

Counter A

Input for reset of counter A.

[63] Counter B (Terminal 29 or 33 only) Input for increment

counting in the SLC counter.

[64] Counter B (Terminal 29 or 33 only) Input for

decrement counting in the SLC counter.

[65] Reset

Counter B

Input for reset of counter B.

[70] Mech. Brake

Feedback

Brake feedback for hoisting applications: Set

1-01 Motor Control Principle to [3] Flux w/

motor feedback; set 1-72 Start Function to [6]

Hoist mech brake Ref.

[71] Mech. Brake

Feedback

inv.

Inverted brake feedback for hoisting

applications

[72] PID error

inverse

When enabled, it inverts the resulting error

from the process PID controller. Available

only if configuration mode is set to "Surface

Winder", "Extended PID Speed OL" or

"Extended PID Speed CL".

[73] PID reset I-

part

When enabled, resets the I-part of the

Process PID controller. Equivalent to

7-40 Process PID I-part Reset. Available only if

configuration mode is set to "Surface

Winder," "Extended PID Speed OL," or

"Extended PID Speed CL".

[74] PID enable Enables the extended process PID controller.

Equivalent to 7-50 Process PID Extended PID.

Available only if configuration mode is set

to "Extended PID Speed OL" or "Extended

PID Speed CL."

[80] PTC Card 1

All digital inputs can be set to [80] PTC Card

1. However, only one digital input must be

set to this choice.

[91] Profidrive

OFF2

The functionality is the same as the control

word bit of the profibus/profinet option.

[92] Profidrive

OFF3

The functionality is the same as the control

word bit of the profibus/profinet option.

[98] Start edge

triggered

Edge triggered start command. Keeps the

start command alive, even if the input is

going back to low. Can be used for a start

push button.

[100] Safe Option

Reset

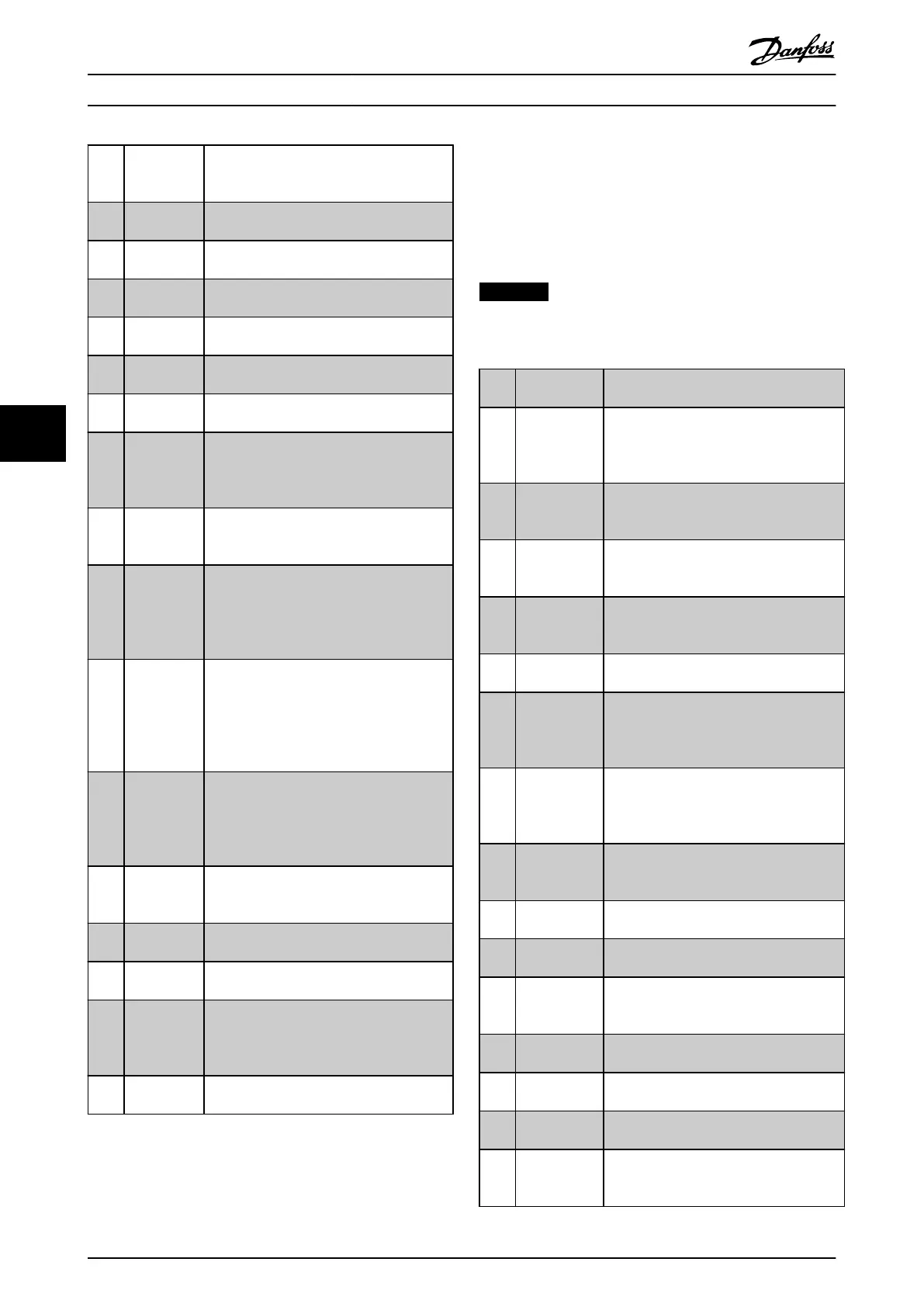

6.1.5 5–3* Digital Outputs

The 2 solid-state digital outputs are common for terminals

27 and 29. Set the I/O function for terminal 27 in 5–

01 Terminal 27 Mode, and set the I/O function for terminal

29 in parameter 5-02 Terminal 29 Mode.

NOTICE

These parameters cannot be adjusted while the motor is

running.

[0] No operation Default for all digital outputs and relay

outputs

[1] Control ready The control card is ready. For example, the

control is supplied by an external 24 V

(MCB 107) and the main power to the unit

is not detected.

[2] Drive ready The frequency converter is ready for

operation and applies a supply signal on

the control board.

[3] Drive ready/

remote

control

The frequency converter is ready for

operation and is in [Auto on] mode.

[4] Enable/no

warning

Ready for operation. No start or stop

command given (start/disable). No

warnings are active.

[5] VLT running Motor is running and shaft torque is

present.

[6] Running/no

warning

Output speed is higher than the speed set

in 1-81 Min Speed for Function at Stop

[RPM]. The motor is running and there are

no warnings.

[7] Run in

range/no

warning

Motor is running within the programmed

current and speed ranges set in

4-50 Warning Current Low to 4-53 Warning

Speed High. There are no warnings.

[8] Run on

reference/no

warning

Motor runs at reference speed. No

warnings.

[9] Alarm An alarm activates the output. No

warnings.

[10] Alarm or

warning

An alarm or a warning activates the

output.

[11] At torque

limit

The torque limit set in 4-16 Torque Limit

Motor Mode or 4-17 Torque Limit Generator

Mode has been exceeded.

[12] Out of current

range

The motor current is outside the range set

in 4-18 Current Limit.

[13] Below current,

low

Motor current is lower than that set in

4-50 Warning Current Low.

[14] Above

current, high

Motor current is higher than that set in

4-51 Warning Current High.

[15] Out of range Output frequency is outside the frequency

range set in 4-52 Warning Speed Low and

4-53 Warning Speed High.

Programming Operating Instructions

64 Danfoss A/S © Rev. 2014-07-29 All rights reserved. MG37A202

66

Loading...

Loading...