3 Product Overview

3.1 Introduction

The VLT

®

HVAC Drive series is designed for the HVAC

market. These drives operate in variable torque mode or

constant torque down to 15 Hz and include special

features and options designed for fan and pump

applications.

The VLT

®

Refrigeration Drive series is designed for use with

refrigeration systems. These drives oer continuous

variable speed control and provide energy savings in a

range of applications including pumps, fans, compressors,

condensers, and evaporators.

The VLT

®

AQUA Drive series is designed for water and

waste water markets. These drives can operate in either

constant torque or variable torque with limited overload

capabilities. Their features and options make them suitable

for various water pumping and processing applications.

The VLT

®

AutomationDrive series is fully programmable for

either constant torque or variable torque industrial

applications. These drives operate various applications and

incorporate a wide range of control and communication

options.

These models are available in IP20 (protected chassis), IP21

(UL type 1), and IP54 (UL type 12) enclosures.

Special versions of these 3 drive types are available as VLT

®

Parallel Drive Modules in IP00 enclosures. They are used by

panel builders to create 2-module or 4-module systems.

NOTICE

PARALLEL MODULE CONFIGURATION

VLT® Parallel Drive Modules have specialized software

and hardware congurations that dier from standalone

D-sized units. To avoid equipment malfunction, never

attempt to replace standalone modules with VLT

®

Parallel Drive Modules.

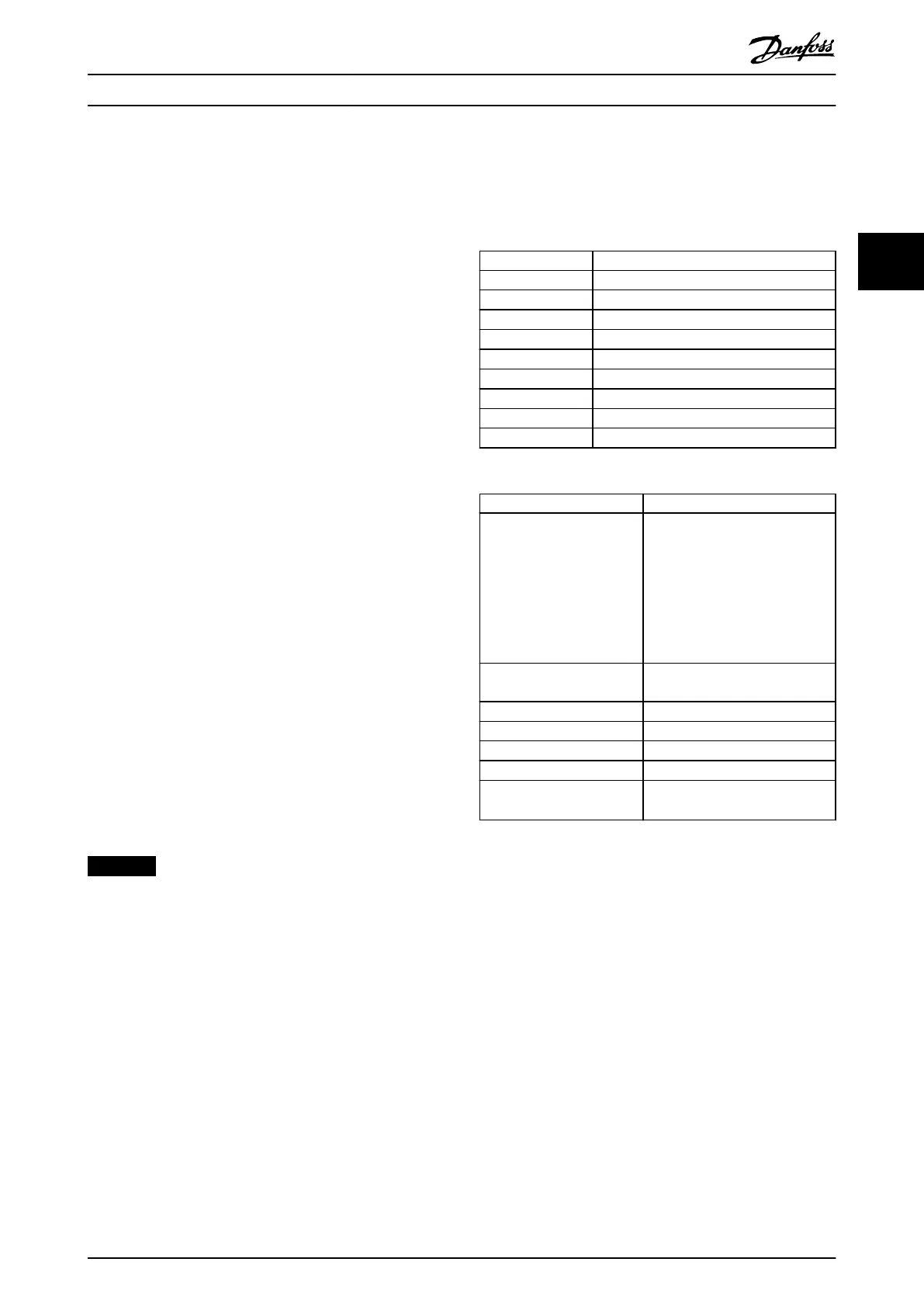

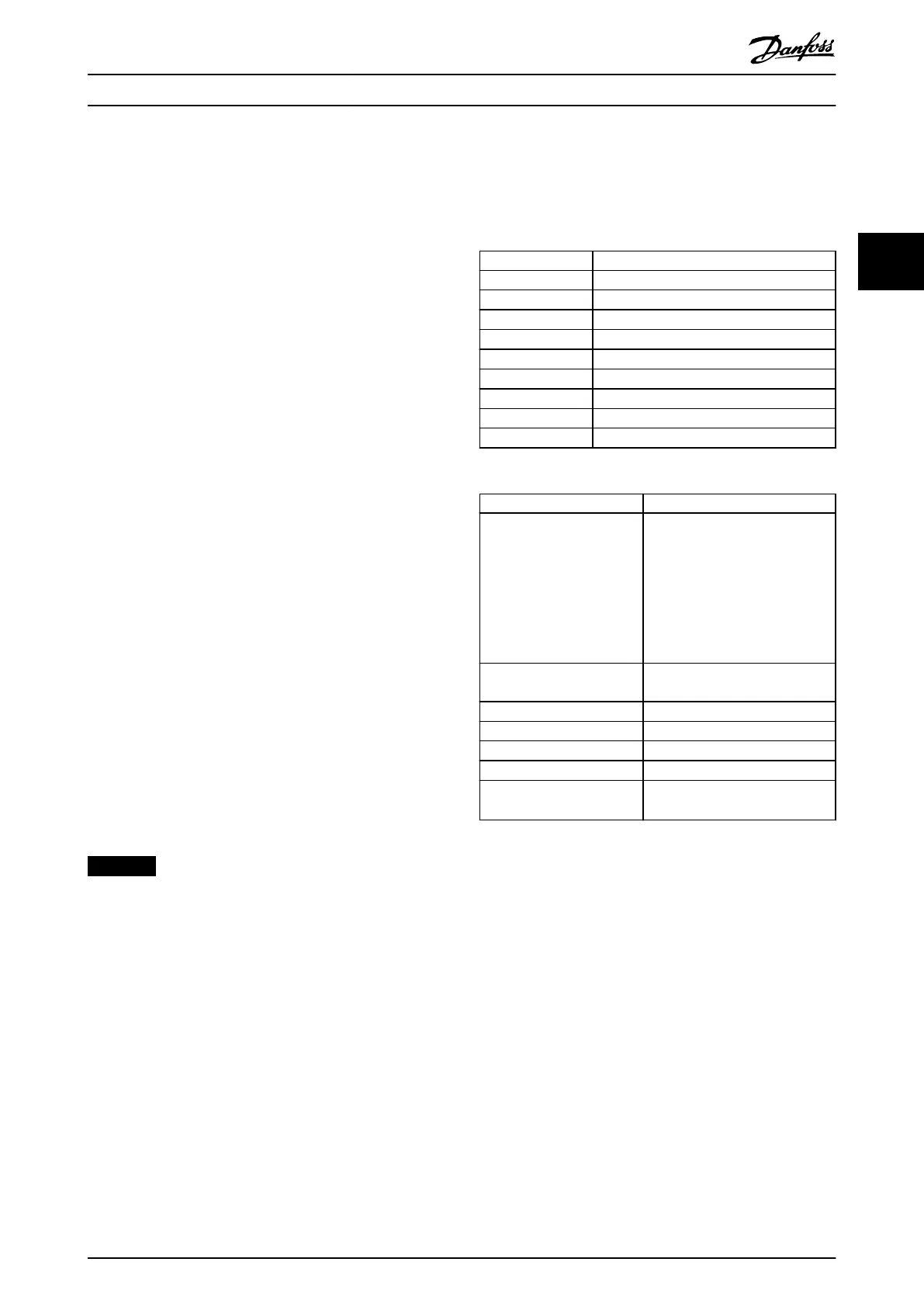

3.2 Tools Required

Item Description

ESD protection kit Wrist strap and mat

Metric socket set 7–19 mm

Socket extensions 100–150 mm (4 in and 6 in)

Magnetic sockets –

Ratchet wrench –

Torque wrench Torque range 0.5–19 Nm (6–170 in-lb)

Torx driver set T10–T50

Needle nose pliers –

Screwdrivers Standard and Phillips

Table 3.1 Tools Required

Item Description

Digital Volt-Ohm Meter

(PWM-compatible)

•

Rated for true RMS.

•

Rated for the mains AC

voltage and DC-link voltage of

the drive.

(DC-link voltage = 1.414 x

mains voltage).

•

Supports the diode mode.

Analog voltmeter (with

safety probe tip extenders)

–

Oscilloscope –

Clamp-on ammeter Rated for true RMS

Split bus power supply p/n 130B3146

Signal test board p/n 176F8437

Parallel drive module service

kit

1)

p/n 176F3745

Table 3.2 Instruments Recommended to Test Drives

1) Used for testing only VLT

®

Parallel Drive Modules.

3.3

Service Report

Report the serial number (S/N) of the drive when

requesting support, or preparing the service report. The

serial number is listed on the nameplate. Refer to

Illustration 3.1 for details.

Product Overview Service Guide

MG94A502 Danfoss A/S © 02/2019 All rights reserved. 15

3 3

Loading...

Loading...