11.2.18 DC Bus Rails

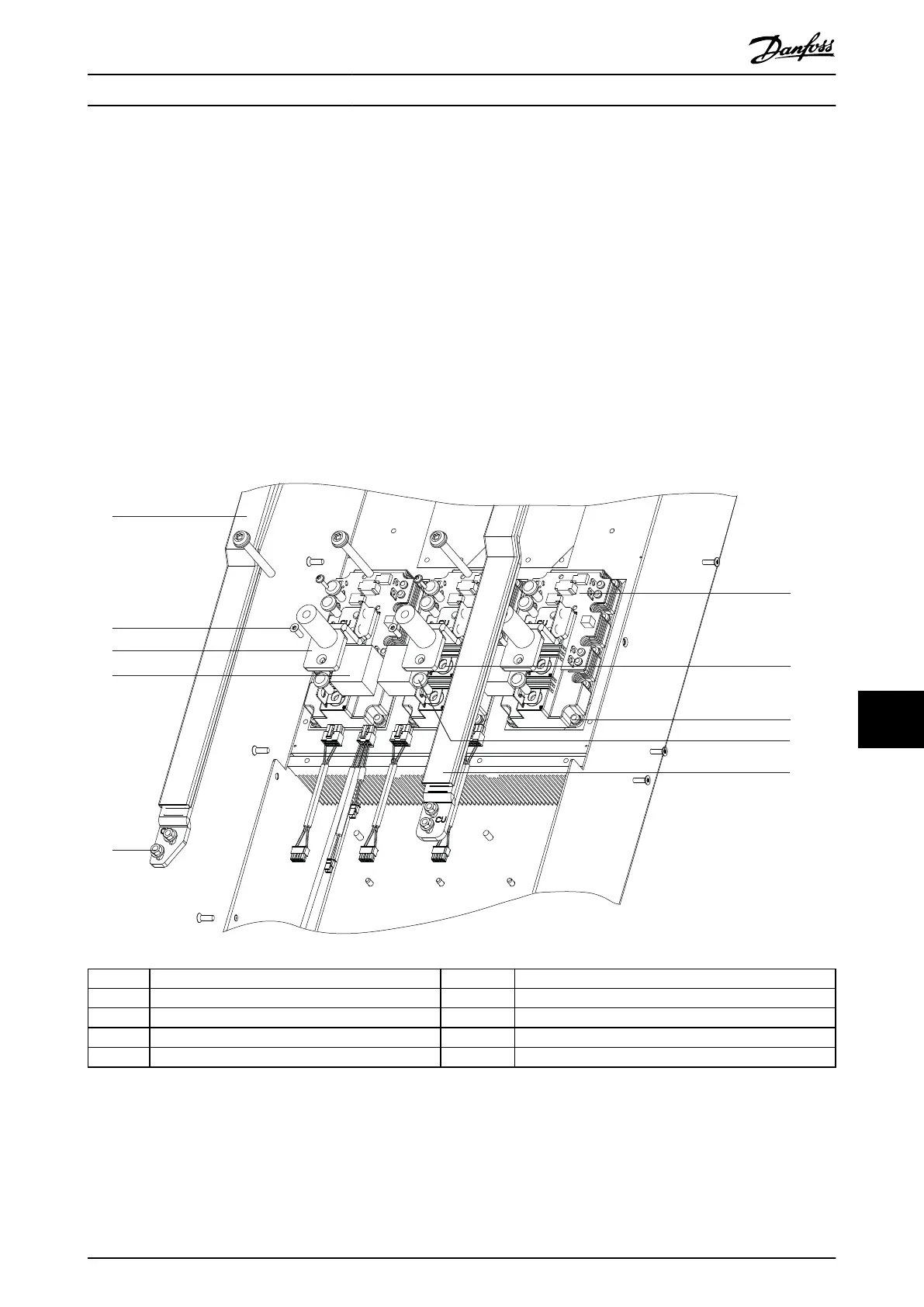

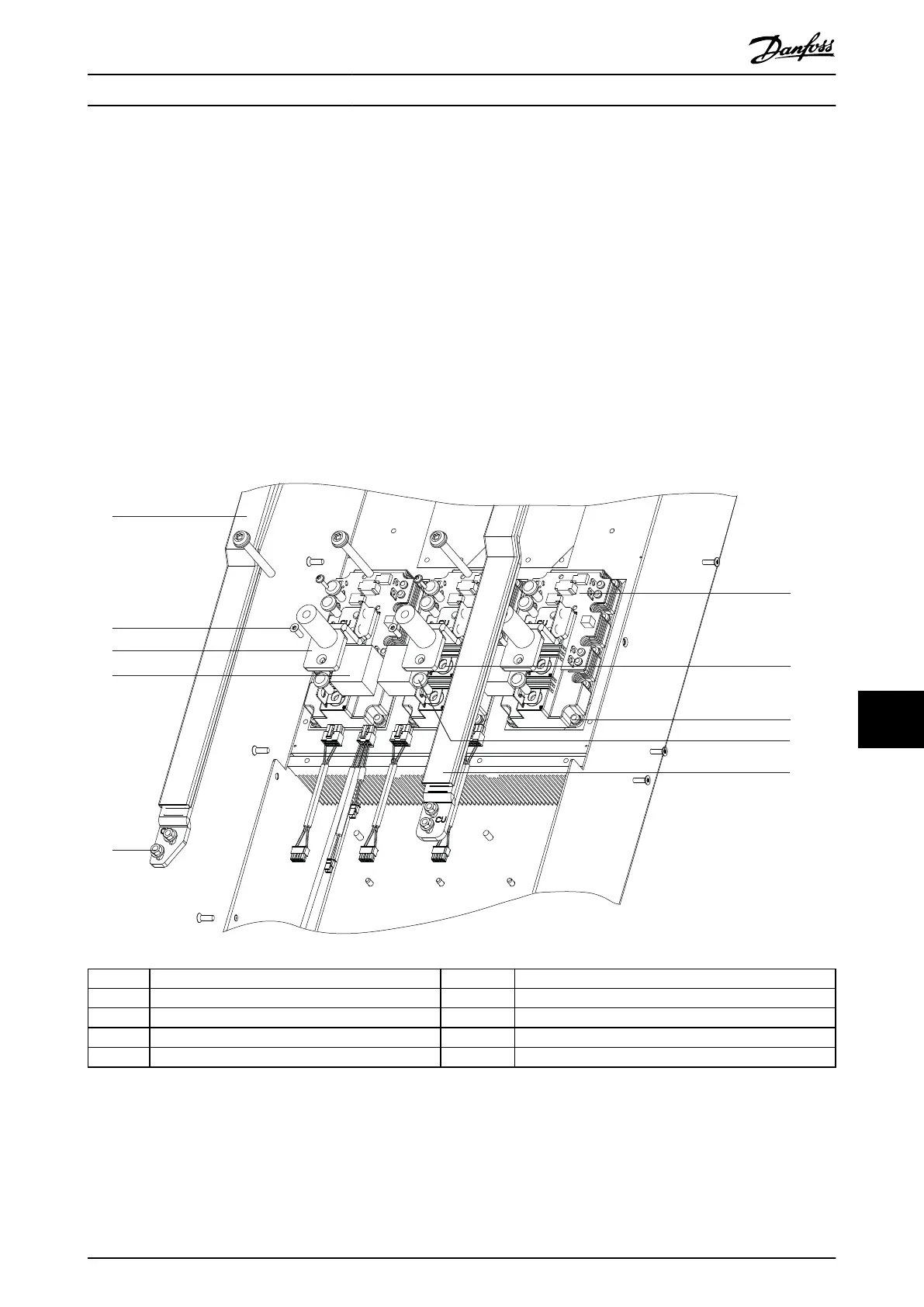

To remove or reinstall the DC bus rails with brake option, use the following steps. Refer to Illustration 11.11.

11.2.18.1 Without Optional Brake

Disassembly

1. Remove the power card mounting plate. Refer to

chapter 11.2.3 Power Card Mounting Plate.

2. Remove the power terminal mounting plate. Refer

to chapter 11.2.11 Power Terminal Mounting Plate.

3. Remove the 2 screws (T40) at the top end of the

DC bus rails, 1 per bus rail.

4. From the lower end of the DC bus rails, remove 4

nuts (10 mm), 2 per bus rail.

Reassembly

Tighten hardware according to chapter 14.1 Fastener Torque

Ratings.

1. Secure 2 screws (T40) at the top end of the DC

bus rails, 1 per bus rail.

2. Fasten 4 nuts (10 mm) at the lower end of the DC

bus rails, 2 per bus rail.

3. Replace the power terminal mounting plate. Refer

to chapter 11.2.11 Power Terminal Mounting Plate.

4. Replace the power card mounting plate. Refer to

chapter 11.2.3 Power Card Mounting Plate.

1 DC(+) bus rail 6 IGBT module

2 Screw (T20) 7 IGBT output busbar

3 IGBT output busbar 8 Screw (T40)

4 Snubber capacitor 9 Screw (T25)

5 Nut (8 mm) 10 DC(-) bus rail

Illustration 11.11 DC Bus Rails without Brake Option

D2h/D4h/D7h/D8h/J9 Unit Dis... Service Guide

MG94A502 Danfoss A/S © 02/2019 All rights reserved. 211

11 11

Loading...

Loading...