14 Product Specications

14.1 Fastener Torque Ratings

14.1.1 General Torque Tightening Values

Use a torque wrench to ensure that correct torque is

applied. Incorrect torque can cause electrical connection

problems. For fastening hardware described in this guide,

use the values listed in Table 14.1 to Table 14.3.

NOTICE

TORQUE VALUES

The torque values in the following tables are not

intended for SCR, diode, or IGBT fasteners. Refer to the

instructions included with those replacement parts for

correct values.

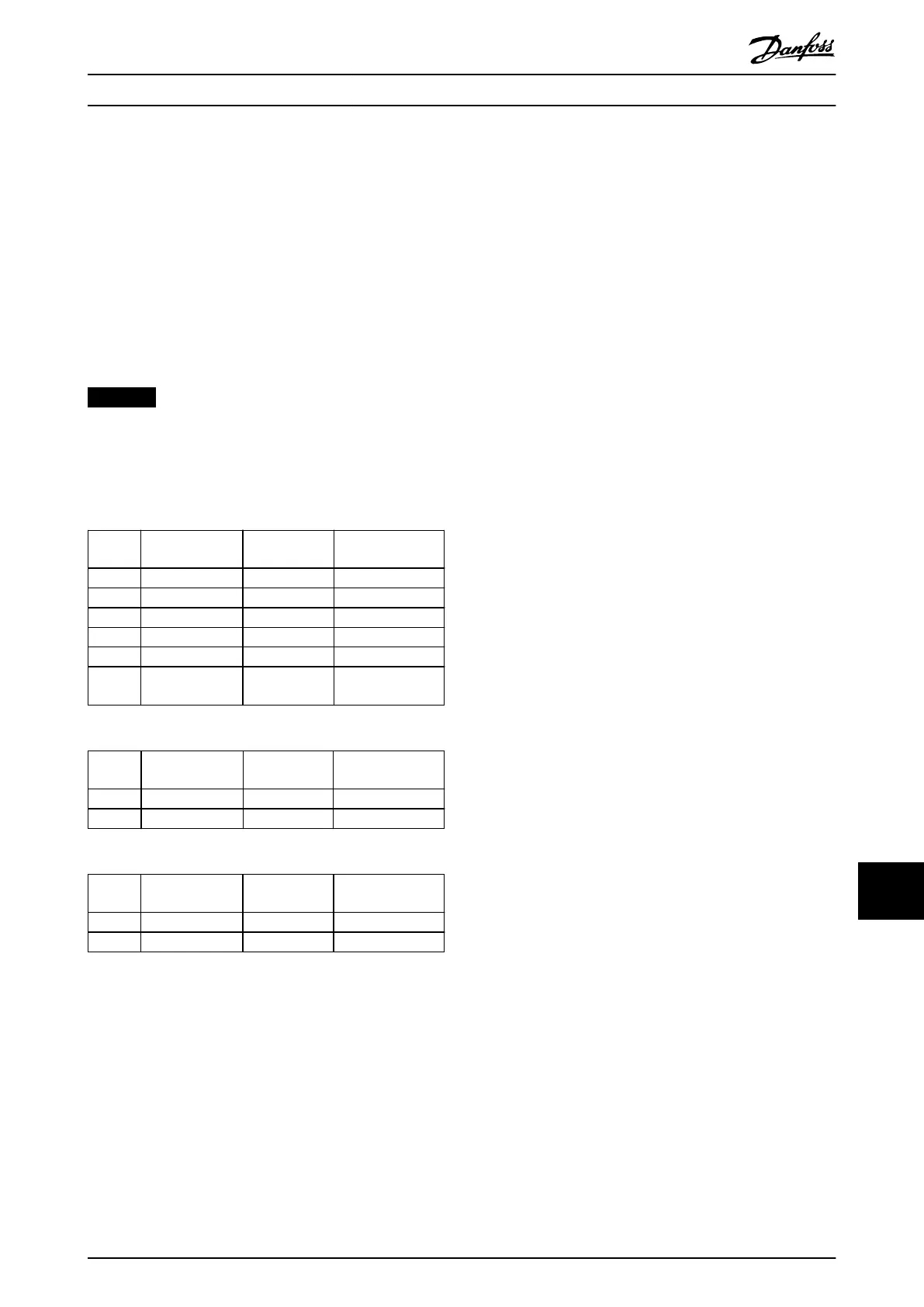

Shaft

size

Torx/hex

drives size

Class A

Nm (in-lb)

Class B

Nm (in-lb)

M4 T20/7 mm 1.2 (10) 0.8 (7)

M5 T25/8 mm 2.3 (20) 1.2 (10)

M6 T30/10 mm 3.9 (35) 2.3 (20)

M8 T40/13 mm 9.6 (85) 3.9 (35)

M10 T50/17 mm 19.1 (169) 9.6 (85)

M12 –/18 mm or

19 mm

37.9 (335) –

Table 14.1 Torque Values Standard Thread

Shaft

size

Torx drives

size

Class A

Nm (in-lb)

Class B

Nm (in-lb)

M4.8 T25 5.7 (50) 3.1 (27)

M5 T25 1.7 (15) 1.7 (15)

Table 14.2 Torque Values for Thread-cutting into Metal

Shaft

size

Torx drives

size

Class A

Nm (in-lb)

Class B

Nm (in-lb)

M4 T20 2.8 (24) 2.8 (24)

M5 T25 5.1 (45) 4.0 (35)

Table 14.3 Torque Values for Thread-forming into Plastic

Class A: Clamping metal

Class B: Clamping PCA or plastic

Product Specications Service Guide

MG94A502 Danfoss A/S © 02/2019 All rights reserved. 319

14 14

Loading...

Loading...